Direct lever overhead valve system

A lever and lever arm technology, applied in the field of directional lever valve jacking system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Before explaining the embodiments of the present invention in detail, it should be understood that the present invention is not limited to the arrangement of components and structural settings in the following drawings and embodiments. The invention can be implemented in a variety of ways. And it can also be understood that the words and technical terms used herein are for the purpose of description, and should not be interpreted as a limitation. The use of "including" and "comprising" and the different embodiments here all mean to include All parts plus additional parts.

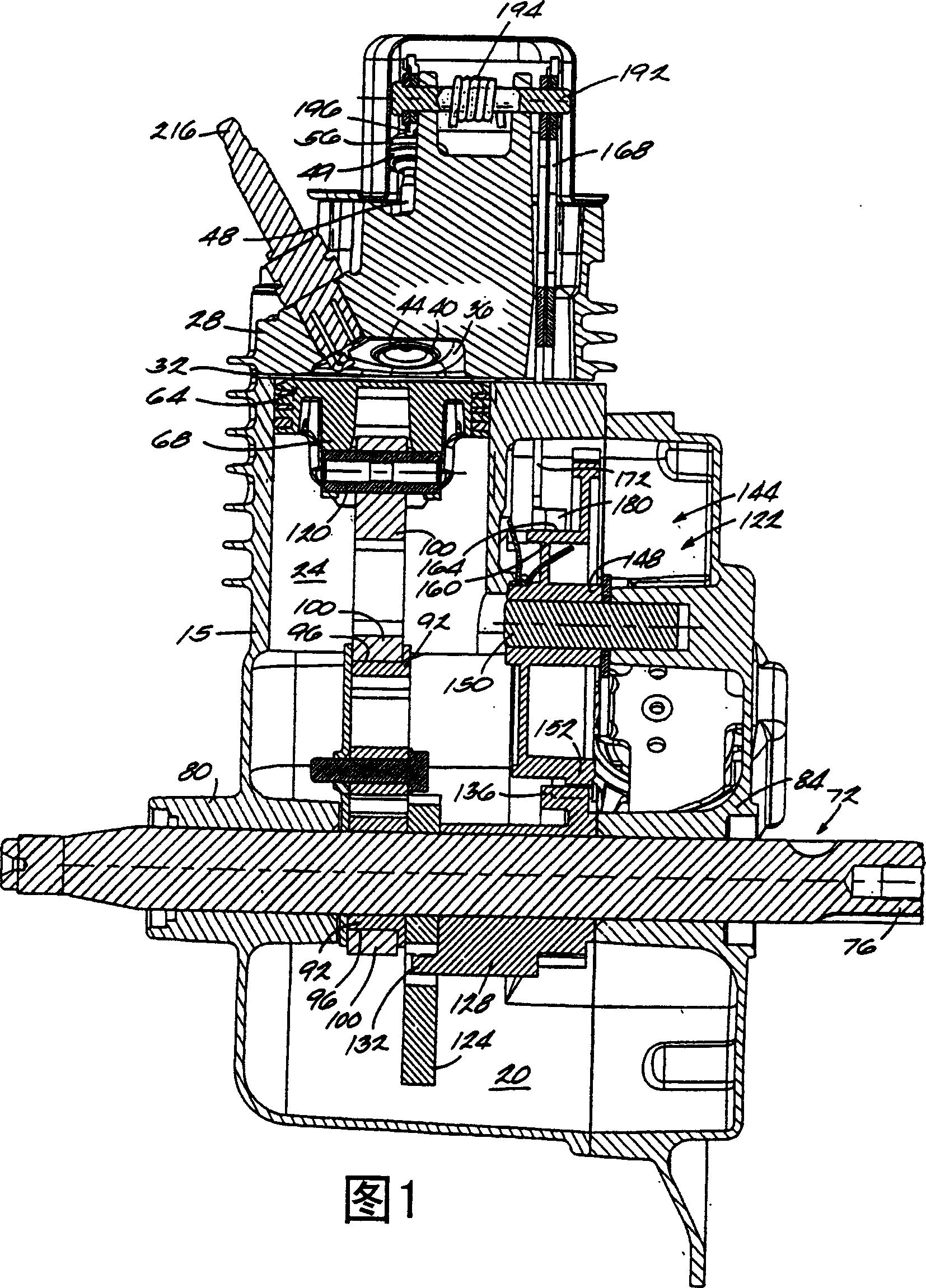

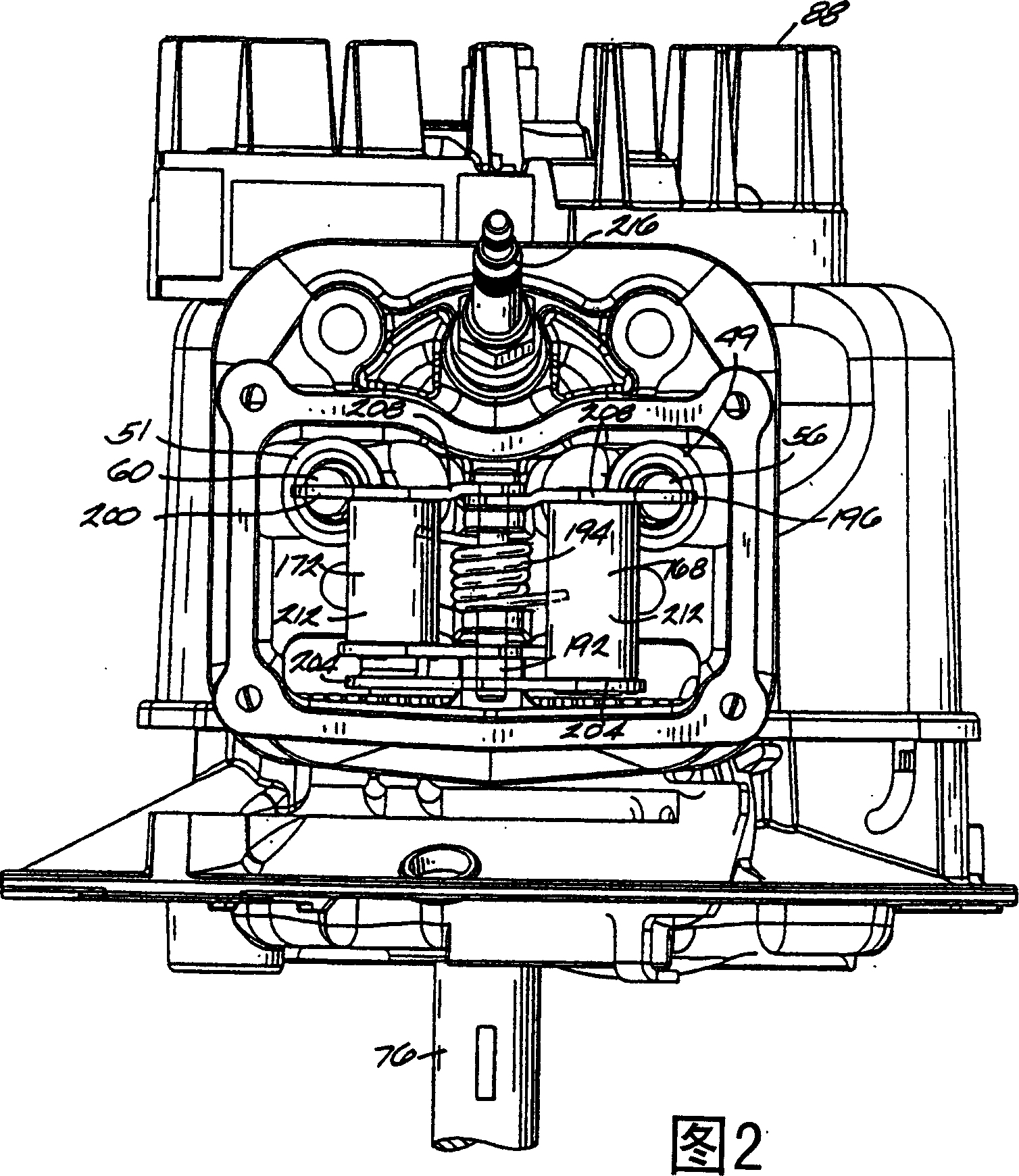

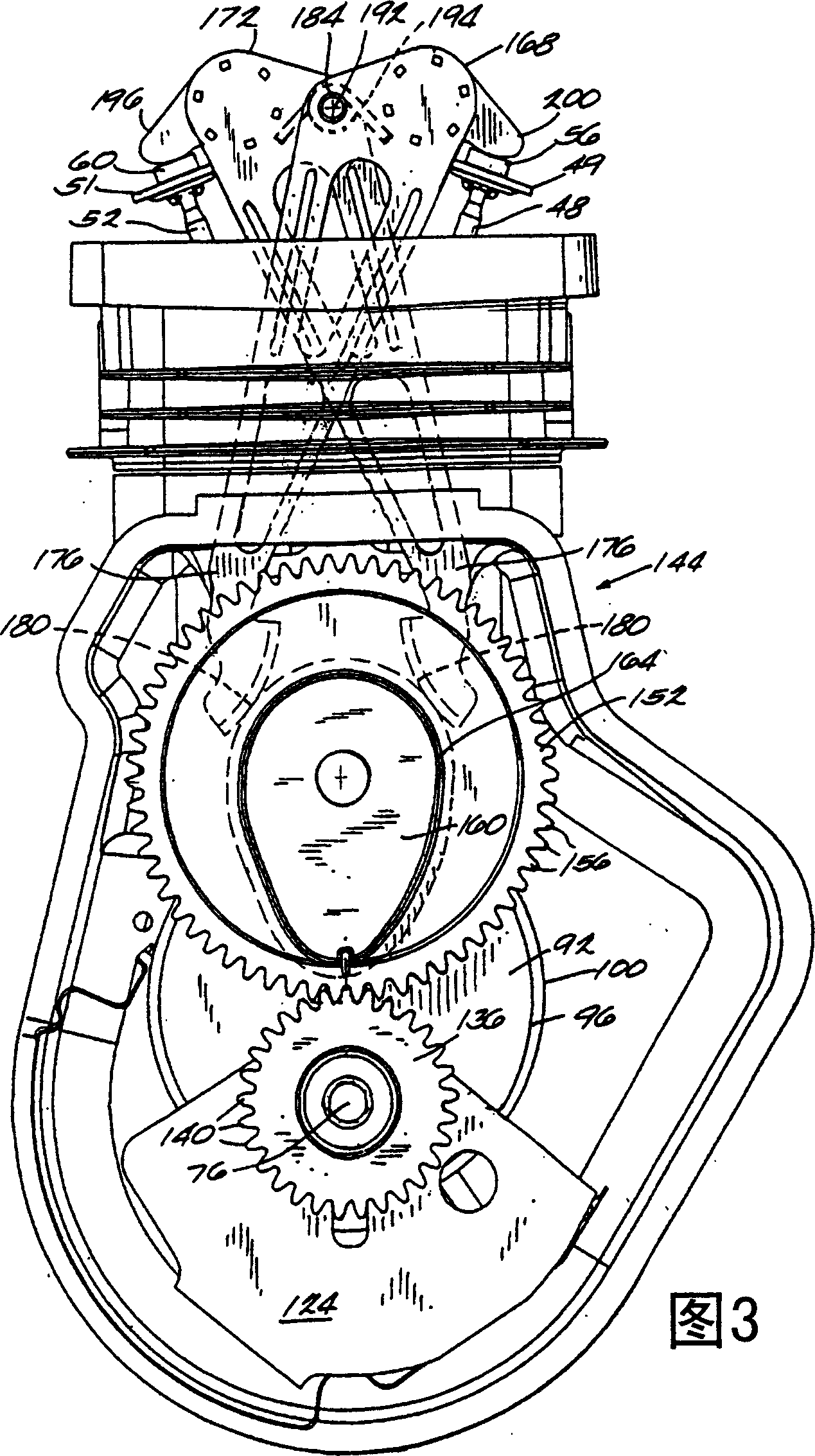

[0021] FIG. 1 is a cross-sectional view of an overhead valve engine 10 . The overhead valve engine includes an engine housing 15 which in turn includes a crankcase 20 and cylinder bores 24 . It should be noted that, here, "outside" refers to the direction away from the crankcase 20, "inside" refers to the direction towards the crankcase 20, and the cylinder bore 24 has an outer end 32, where the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com