Automatic cooking machine and cooking gas regulating system

An adjustment system and automatic cooking technology, applied to cooking utensils, timing control ignition mechanisms, household appliances, etc., can solve the problem of not dynamically considering the fire state, failing to find an accurate detection method for the fire state, means of fire power, complicated heat transfer methods, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

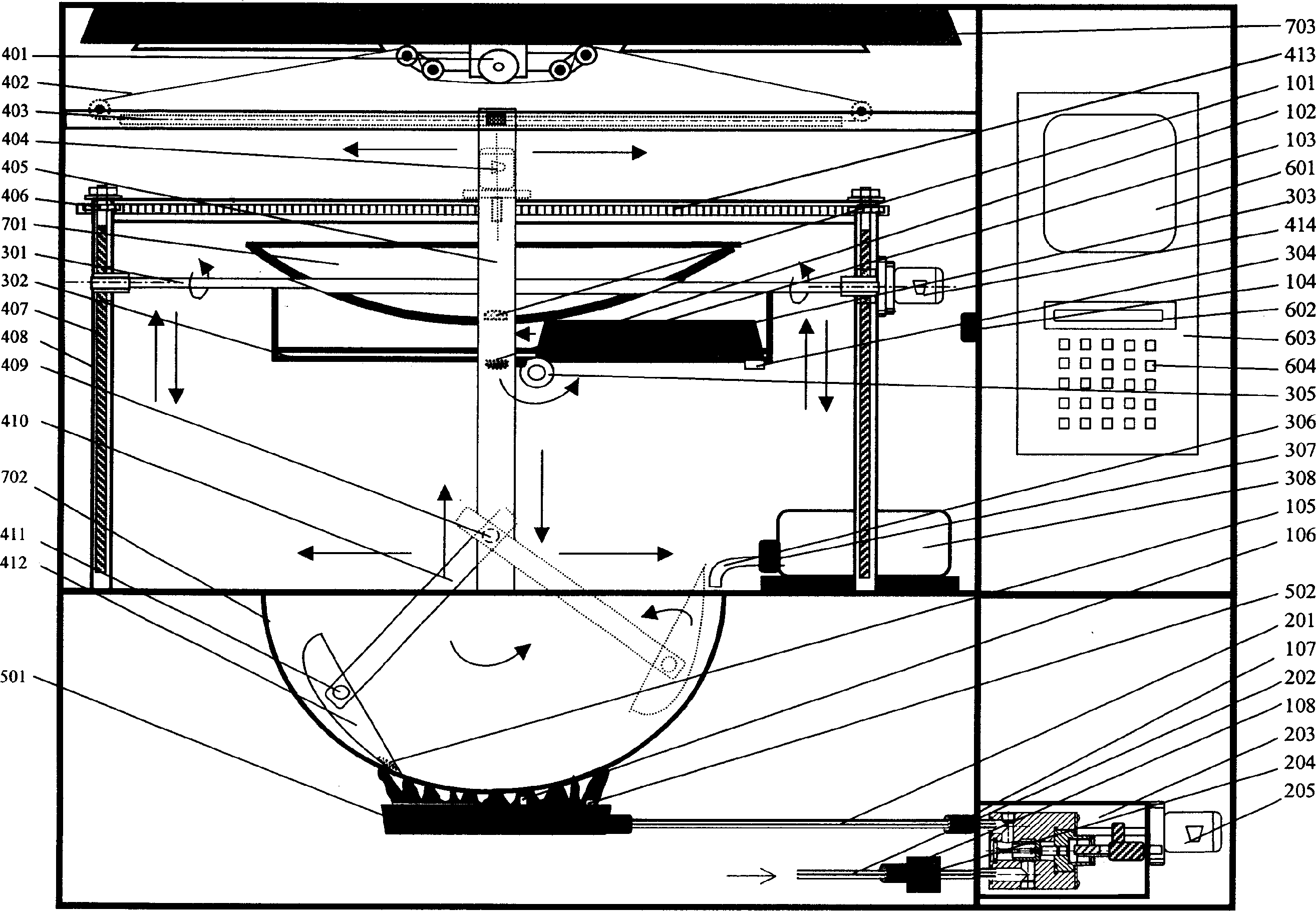

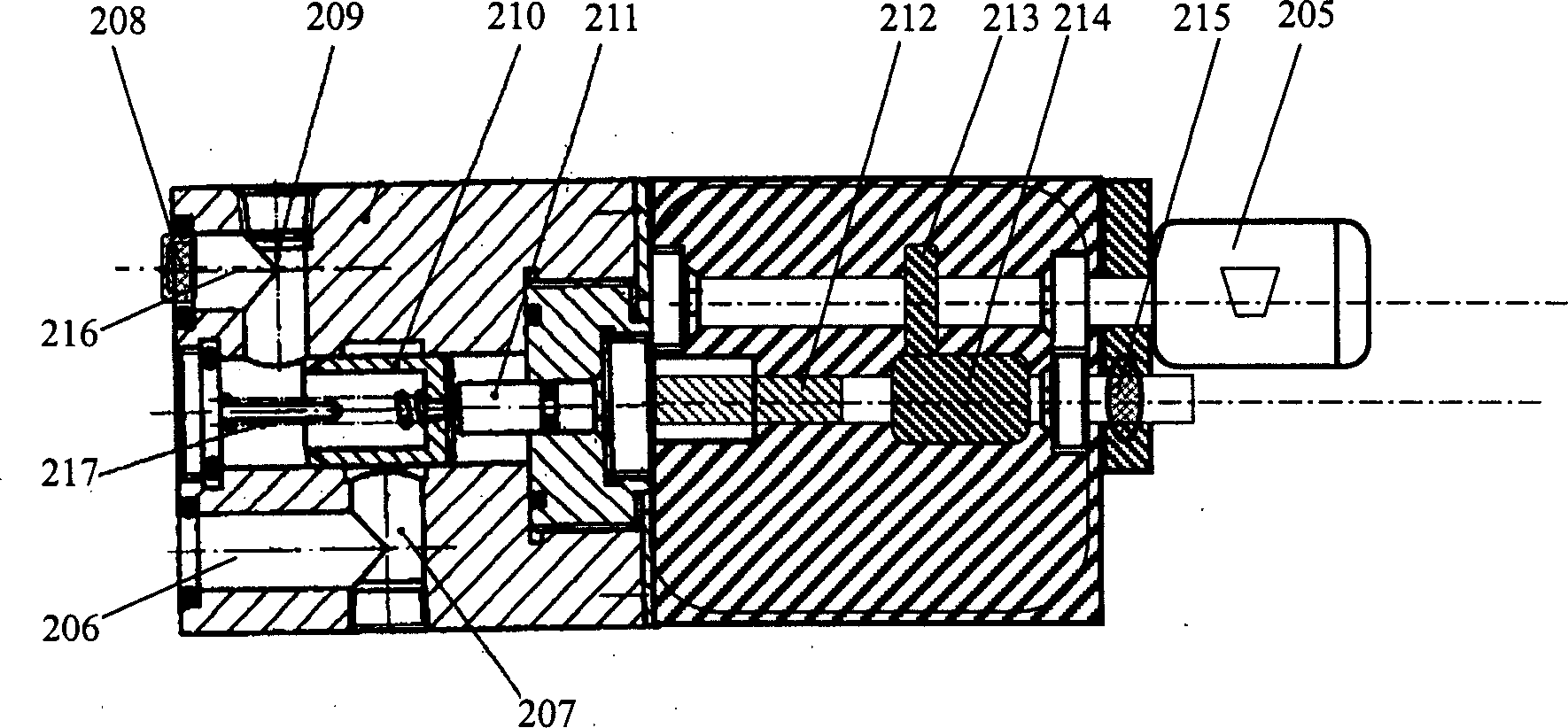

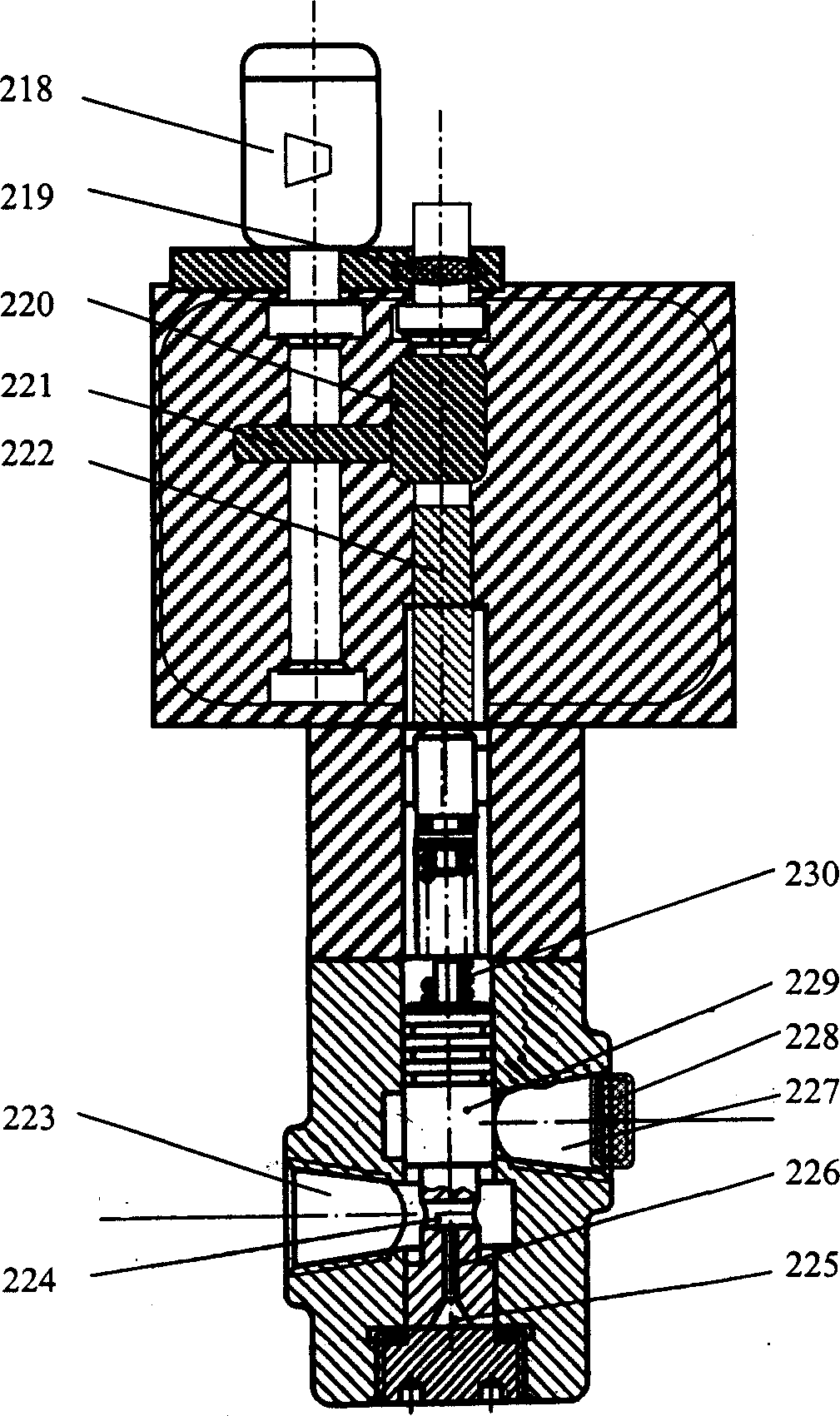

[0050] like Figure 17 As shown: a cooking gas fire power adjustment system, including a gas stove 241, characterized in that: the gas fire power adjustment system includes a sensor 100, a processing circuit 810, a gas regulator 252, the above-mentioned sensor 100, processing circuit 810, The gas regulator 252 is connected to form a control loop for the gas stove 241, the heat transfer medium, and the material to be cooked. The processing circuit 810 detects the value obtained by the sensor 100 according to its own or an external cooking control program. After processing, a gas adjustment instruction is sent to the gas regulator 252 .

[0051] The sensor 100 includes heat state sensors 112, 111 for detecting heat transfer medium, cooked materials, etc., which are related to the heat, and the heat state sensors 112, 111 are connected with the processing circuit 810 and the gas regulator 252 to form a main fire control loop. road.

[0052] The sensor 100 also includes operatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com