System and method for making, mounting and filling fluid product dispensing device

A technology for dispensing devices and fluid products, which can be used in spraying devices, packaging, packaging protection, etc., and can solve problems such as no guarantee of disinfection of puncture needles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

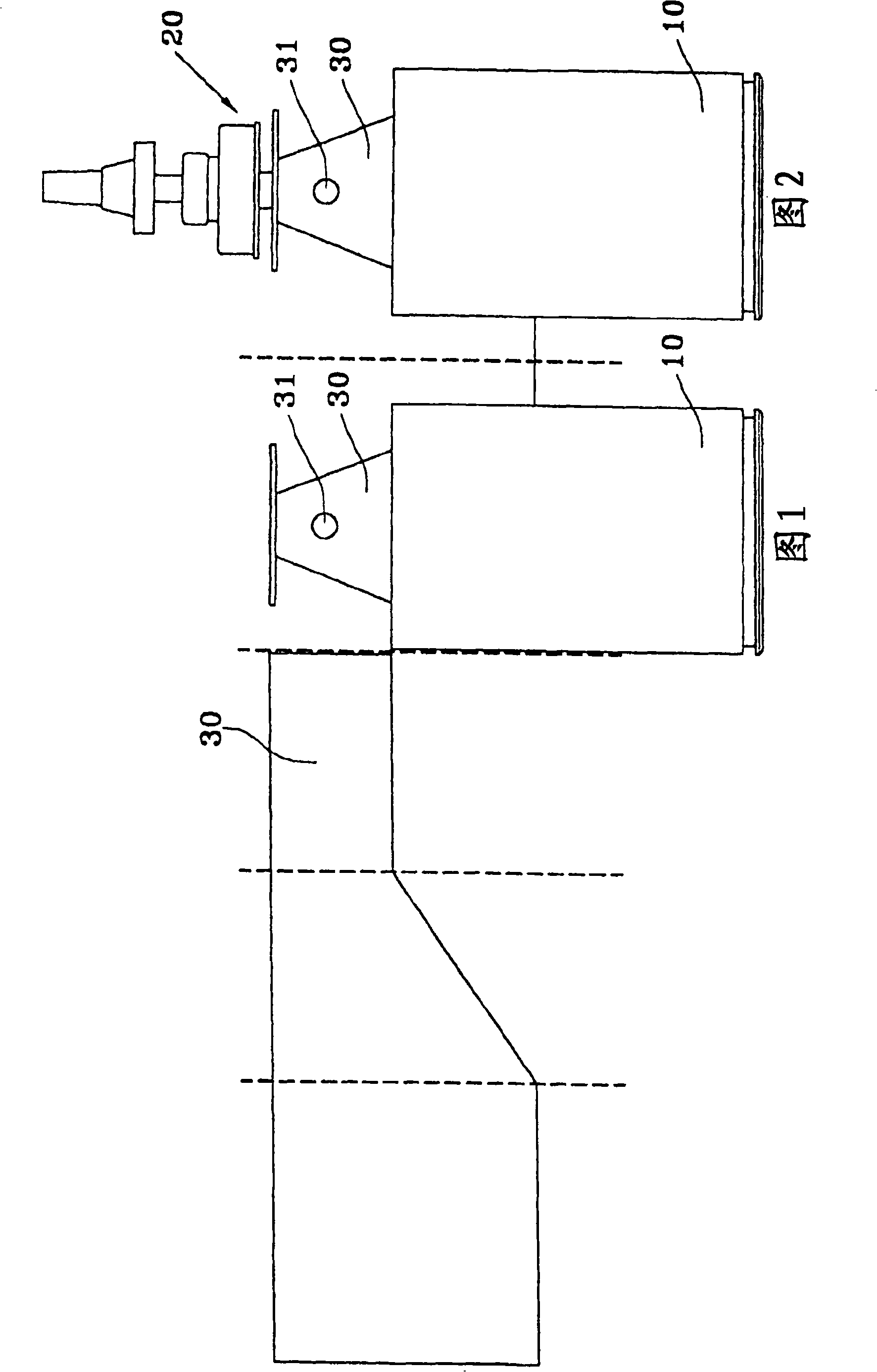

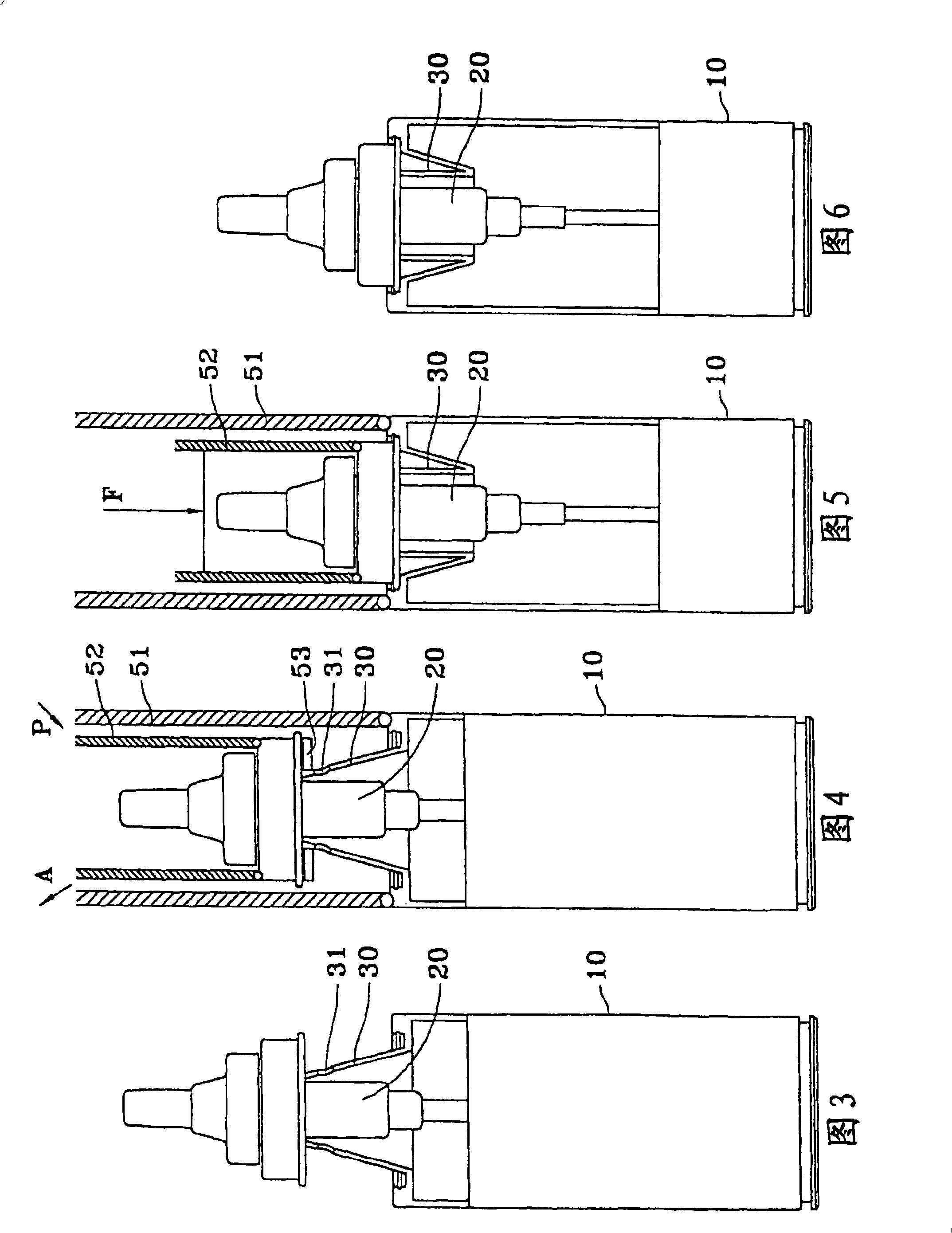

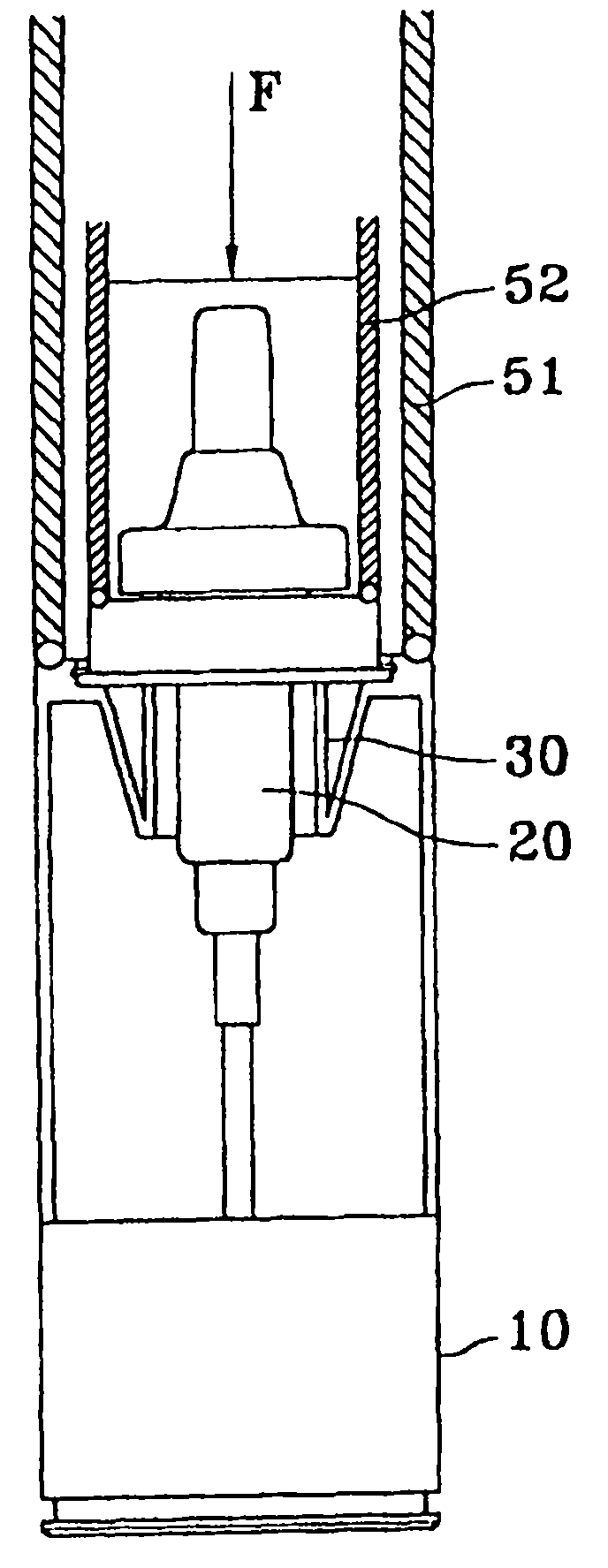

[0032] A particular embodiment of the invention is shown in the figure. In this embodiment, a system is provided for manufacturing, assembling and filling a fluid dispensing device comprising a product container 10 on which a dispensing member 20, such as a pump, is assembled.

[0033] According to the invention, the system comprises a device for manufacturing a container 10, a device for filling said container 10 and a fixing device for fixing said dispensing member 20 on said container 10, said device being in a controlled environment Medium, especially continuous operation under sterile conditions. Thus, the system of the present invention makes it possible to carry out all the steps of the manufacturing, filling and assembling process of the fluid product dispensing device in the same controlled environment without any interruption, which guarantees the absolute sterility of the final product.

[0034] Referring to the drawings showing a particular embodiment, the contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com