Backflow brazier

A technology of reflow soldering furnace and closed cavity, which is applied in the direction of welding equipment, welding equipment, manufacturing tools, etc., and can solve the problem of insufficient application of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

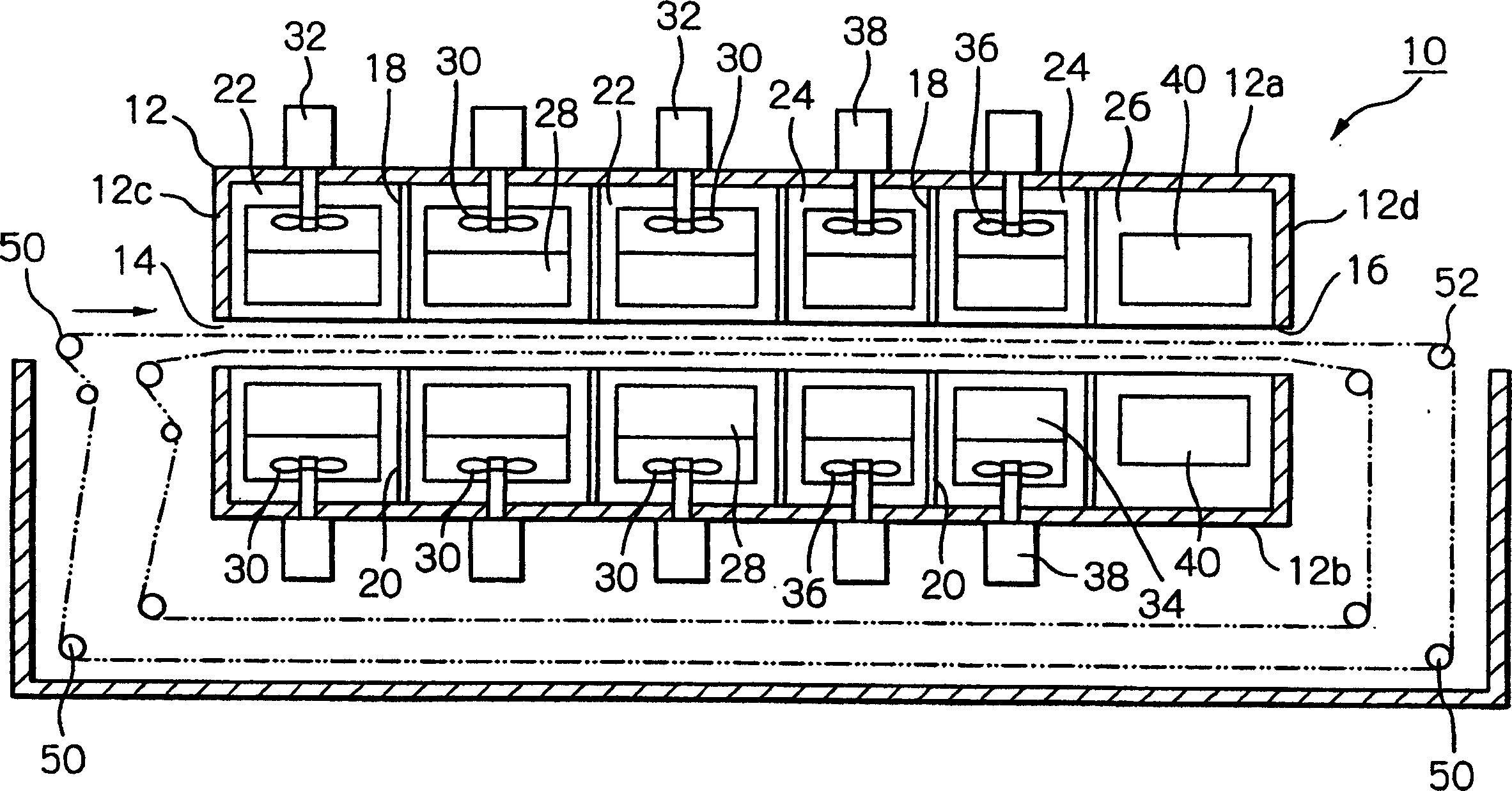

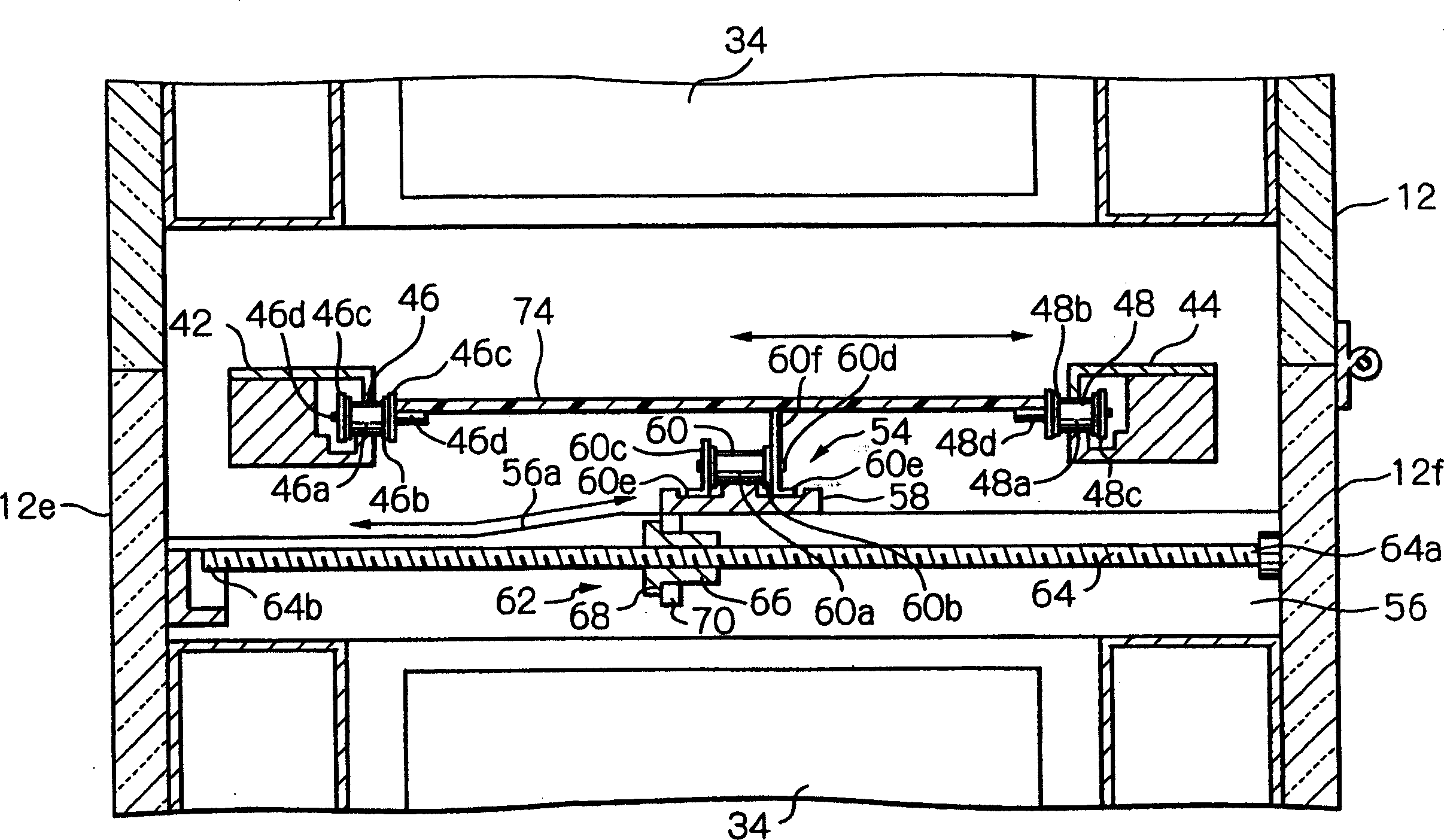

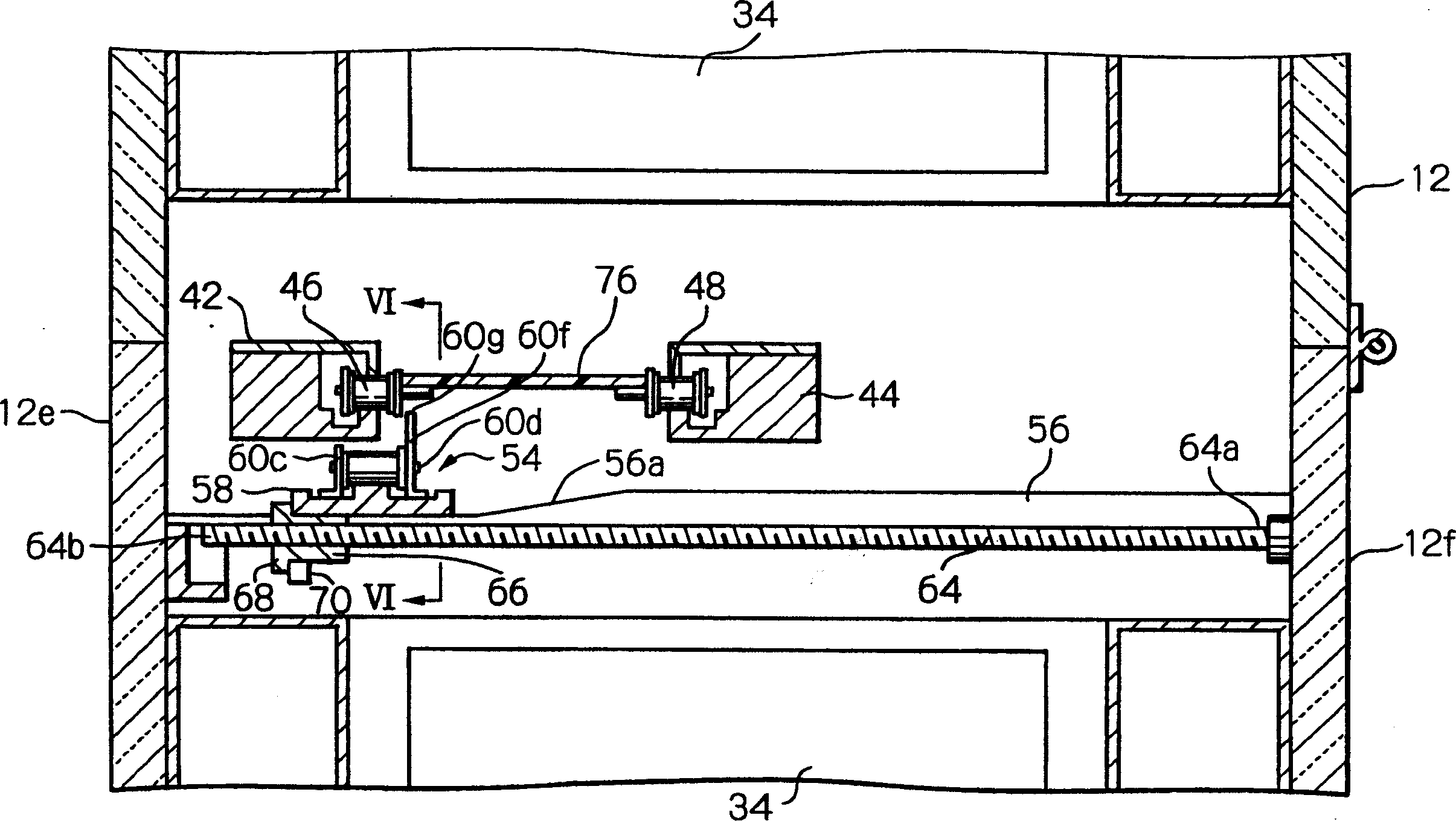

[0014] First refer to figure 1 , shows a reflow oven according to an embodiment of the present invention, and is indicated by reference numeral 10 . The reflow oven 10 has a closed cavity 12, which is composed of a top wall 12a, a bottom wall 12b, a front wall 12c between the top wall and the bottom wall 12a, 12b, and a rear wall between the top wall and the bottom wall 12a, 12b. A wall 12d, and two side walls 12e, 12f connecting all other walls 12a to 12b are formed. The front wall 12c has an inlet 14 and the rear wall 12d has an outlet 16 aligned horizontally with the inlet 14 . The reflow oven 10 includes a number of pairs of upper and lower baffles 18, 20 to form six independent vertical zones, that is, three preheat zones 22, two reflow zones 24 disposed downstream of the preheat zones 22, and A cooling zone 26 downstream of the recirculation zone 24 . Each preheat zone 22 is provided with mutually juxtaposed tip and bottom independent heaters 28,28. A corresponding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com