Backlight module

The technology of a backlight module and a light source module, which is applied in the directions of optics, nonlinear optics, identification devices, etc., can solve the problems of uneven illumination intensity, poor display quality of the display panel 12, and uneven distribution of illumination intensity, etc., so as to improve product quality. Competitiveness, guaranteed display quality, evenly distributed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

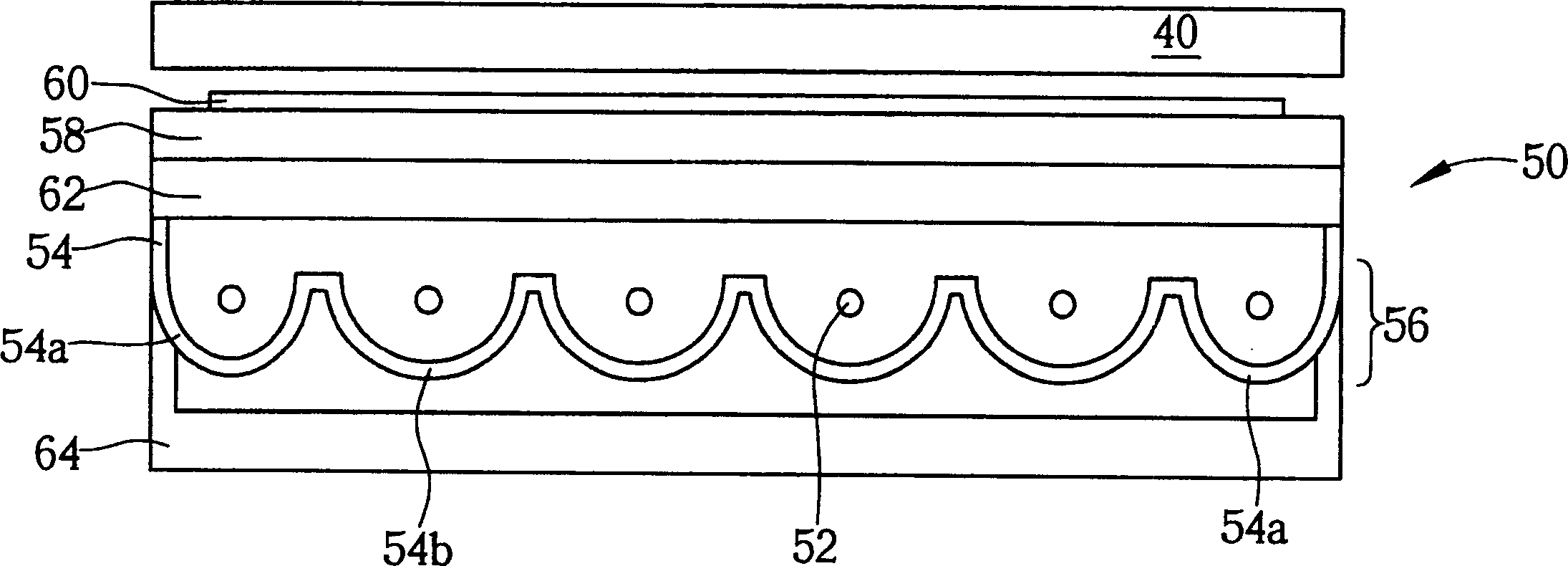

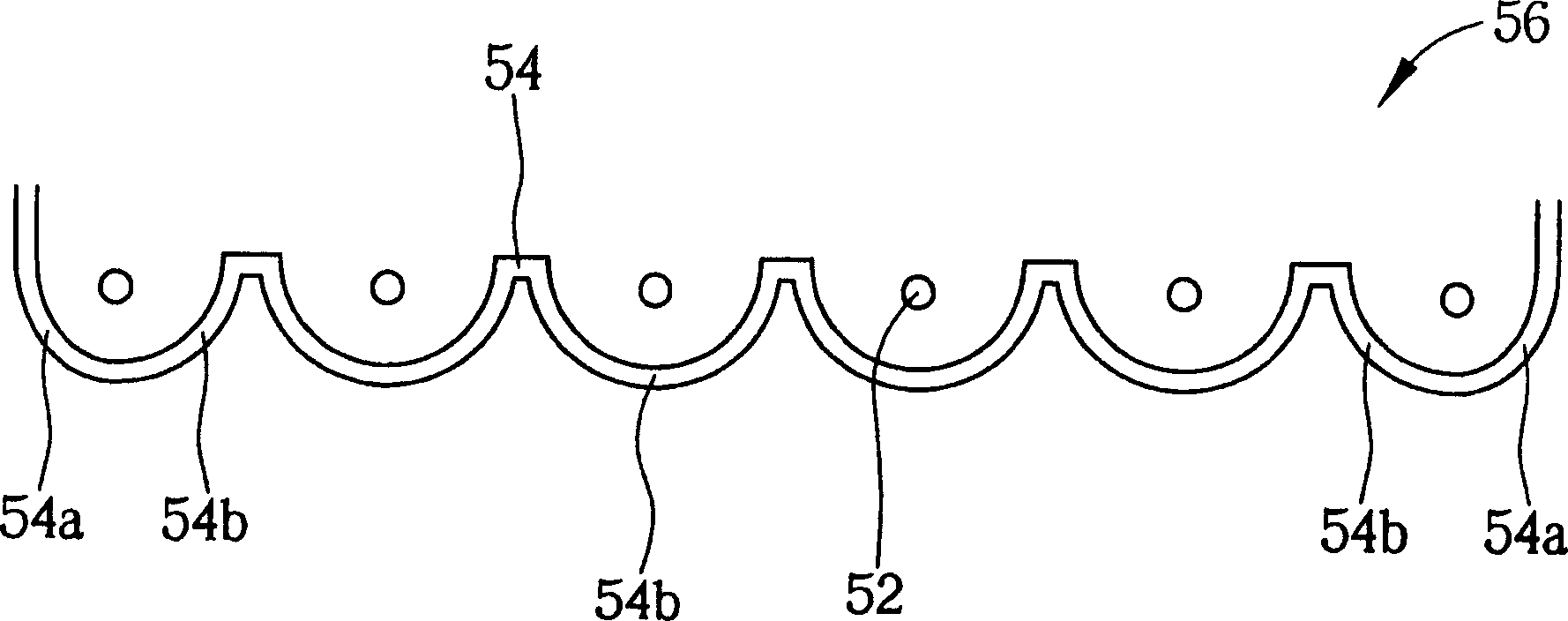

[0022] Please refer to figure 2 , figure 2 It is a schematic cross-sectional view of a back light module 50 of the present invention. Such as figure 2 As shown, the backlight module 50 is arranged below a display panel (display panel) 40, and the backlight module 50 includes a reflective plate ( A light source module (light source unit) 56 composed of a reflecting sheet 54, a diffusing plate (diffusing plate) 58 disposed between the light source generator 52 and the display panel 40, at least one prism (prism) 60 disposed on the surface of the diffusing plate 58 , a light guide plate (LGP) 62 disposed between the light source generator 52 and the diffuser plate 58 , and a housing (housing) 64 disposed below the reflective plate 54 and wrapping around the reflective plate 54 .

[0023] The light source generators 52 are lamp tubes arranged in parallel to provide a light source (not shown), and the reflector 54 is used to reflect the light source upward to the display pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com