Surface light source device

A surface light source and light source technology, which is applied in the direction of optics, nonlinear optics, diffuser elements, etc., can solve the problems of uneven light output and inability to change the local luminance of light, and achieve uniform output of light, change of luminance of light output, and uniform light output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

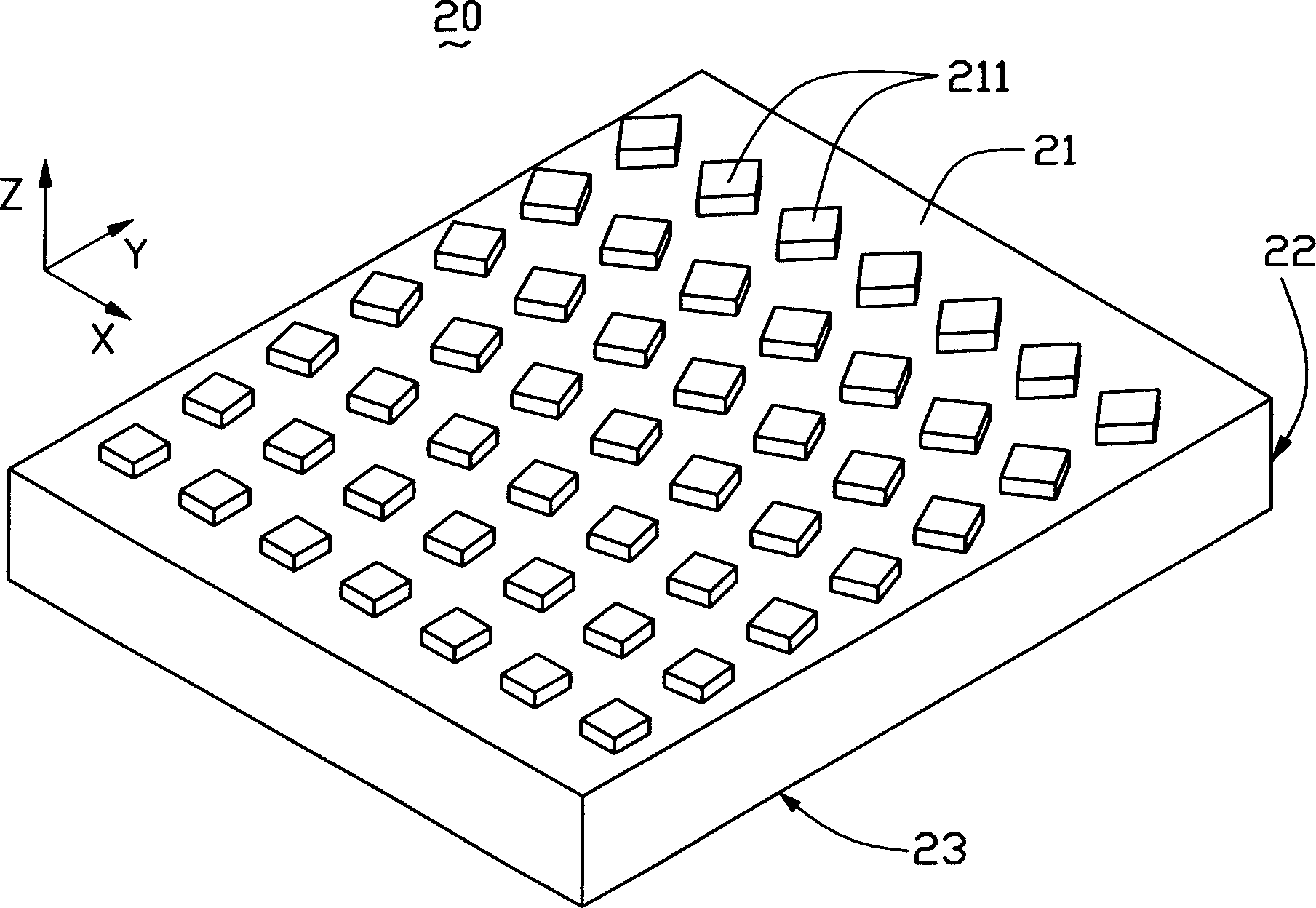

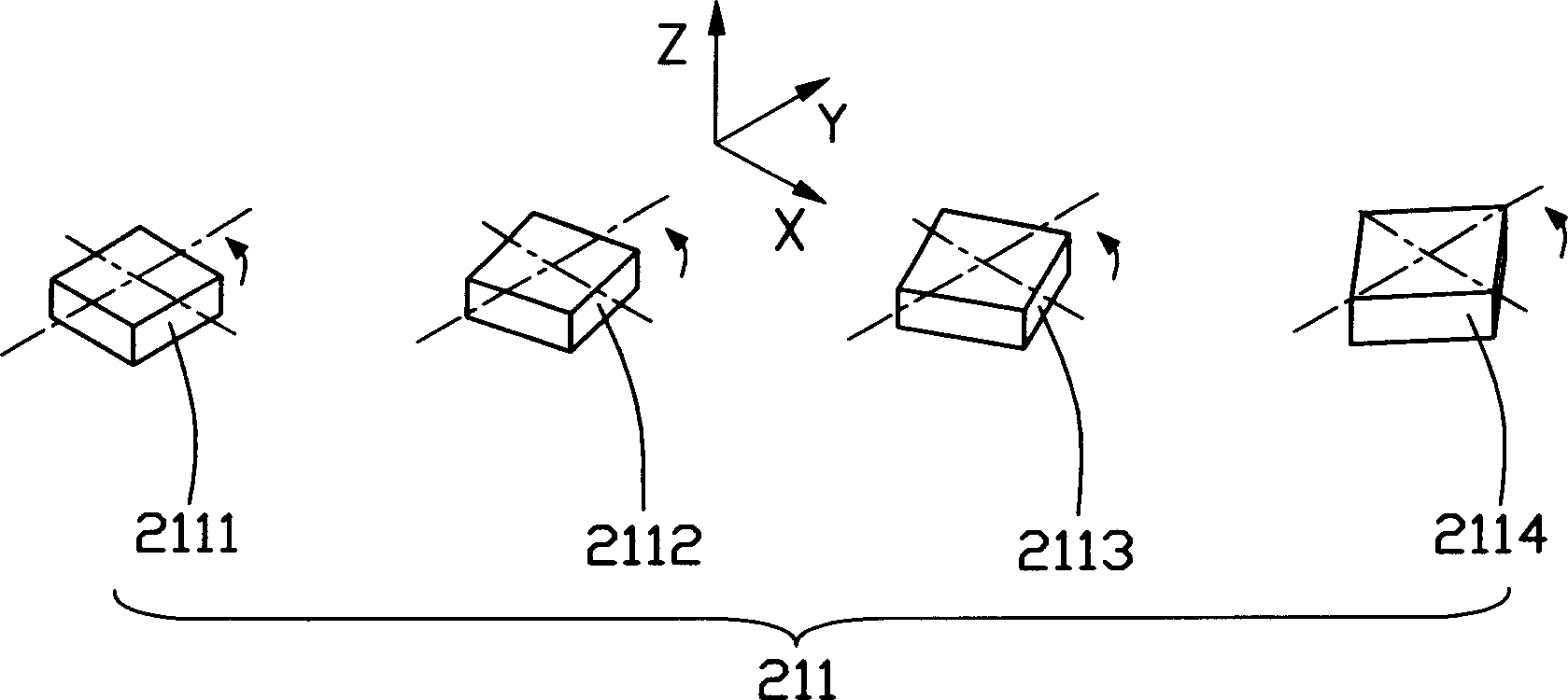

[0016] Light guide plate of the present invention such as figure 2 shown. The light guide plate 20 includes a light incident surface 22 for receiving incident light, a light exit surface 23 adjacent to the light incident surface 22, and a bottom surface 21 opposite to the light exit surface 23, wherein the bottom surface 21 is provided with Scattering point array 211, the arrangement of scattering points in the scattering point array 221 is as follows image 3 shown. Each scattering point in the scattering point array 221 is a rectangular scattering point with the same shape and size, and they are distributed on the bottom surface 21 with the same density. Each scattering point in the scattering point array 211 has a different angular distribution relative to the horizontal plane XY, that is, the scattering points 2112, 2113, 2114 rotate at different angles along the Z axis relative to the scattering point 2111, wherein the Z axis and the light incident surface 22 parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com