Mounting structure of rubber buffer for connector of stock

A technology for rolling stock, mounting structures, used in buffers, rail car body components, transportation and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

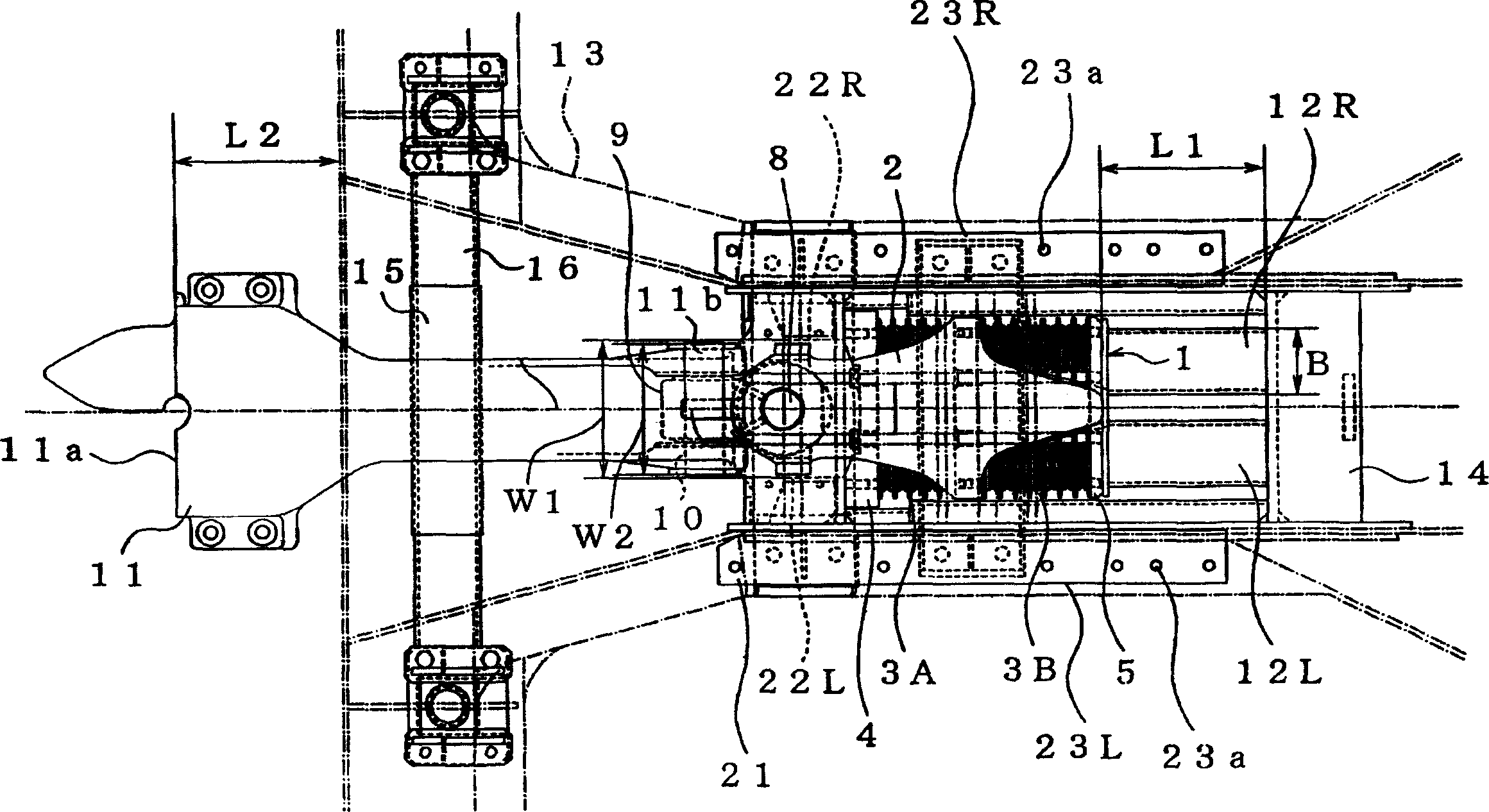

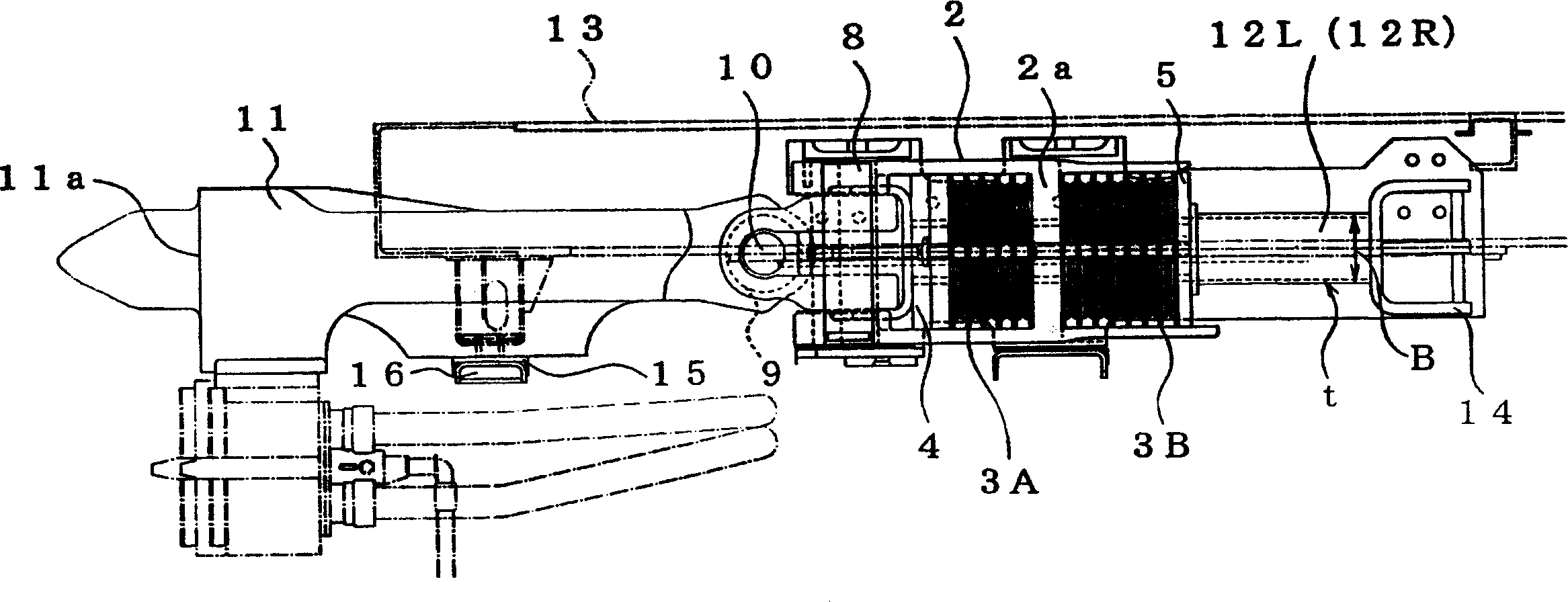

[0037] Embodiments of the present invention will be described below with reference to the drawings.

[0038] like figure 1 and figure 2 As shown, at the frontmost part (or rear end) of the railway vehicle, the rubber buffer 1 is connected to the rear end of the connector 11, and a square cylinder is arranged side by side symmetrically on the rear side of the rubber buffer 1 for absorbing Shock fittings 12L, 12R. That is, the connector 11, the rubber bumper 1, and the pipes 12L, 12R for absorbing shock are sequentially arranged in the front-rear direction of the vehicle body. The vehicle body underframe 13 bears the impact load in the front-rear direction of the vehicle body through the pipes 12L and 12R for absorbing impact. The structure of the rubber buffer 1 is basically the same as the rubber buffer described in the prior art column.

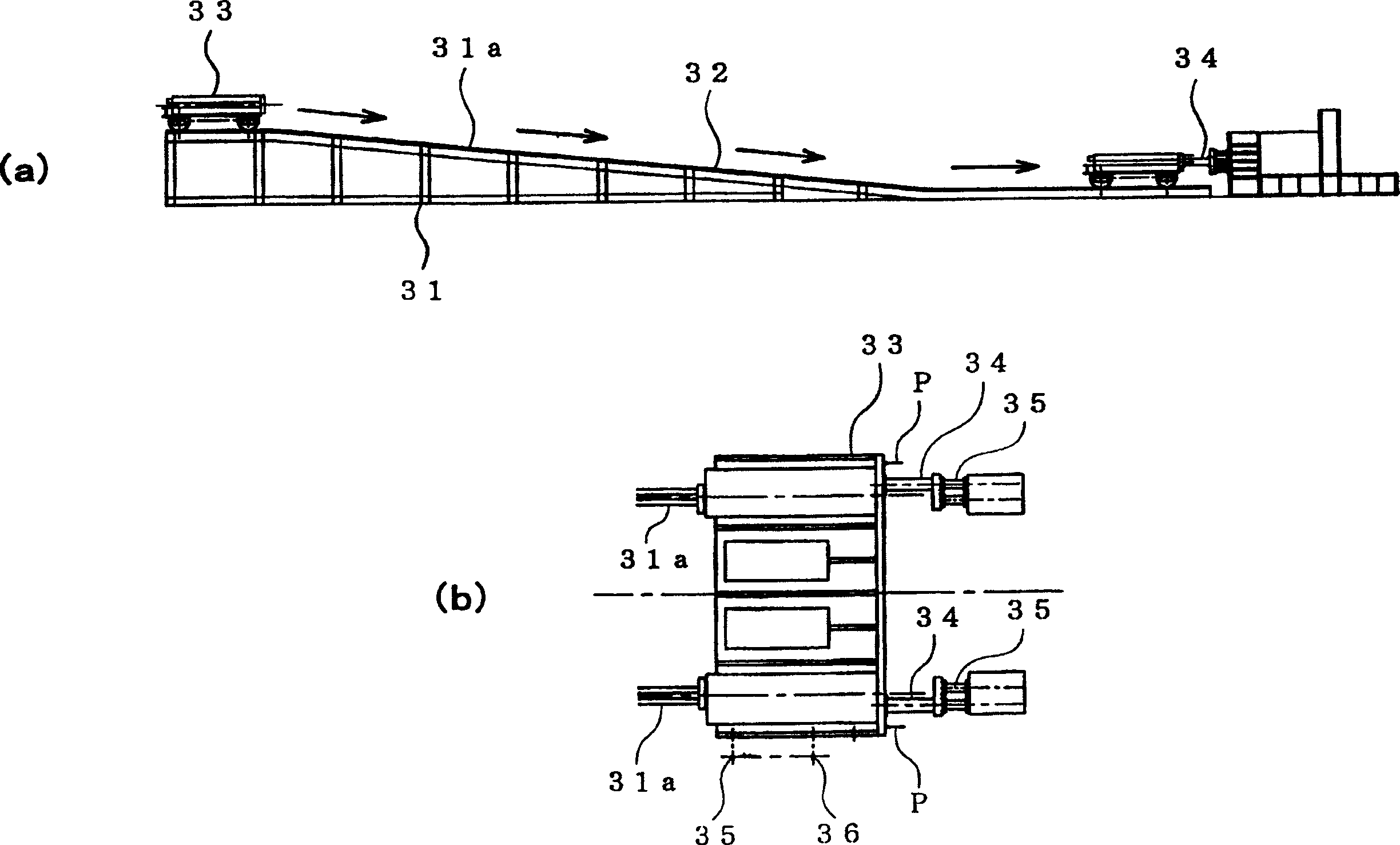

[0039] The impact-absorbing pipe members 12L, 12R are constructed in a closed-section structure (square-section pipe) having four pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com