Instrument exchanging device

A tool exchange, tool technology, used in positioning devices, manufacturing tools, transportation and packaging, etc., can solve problems such as applying impact load, loosening rod wear, loosening pin wear and loosening time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

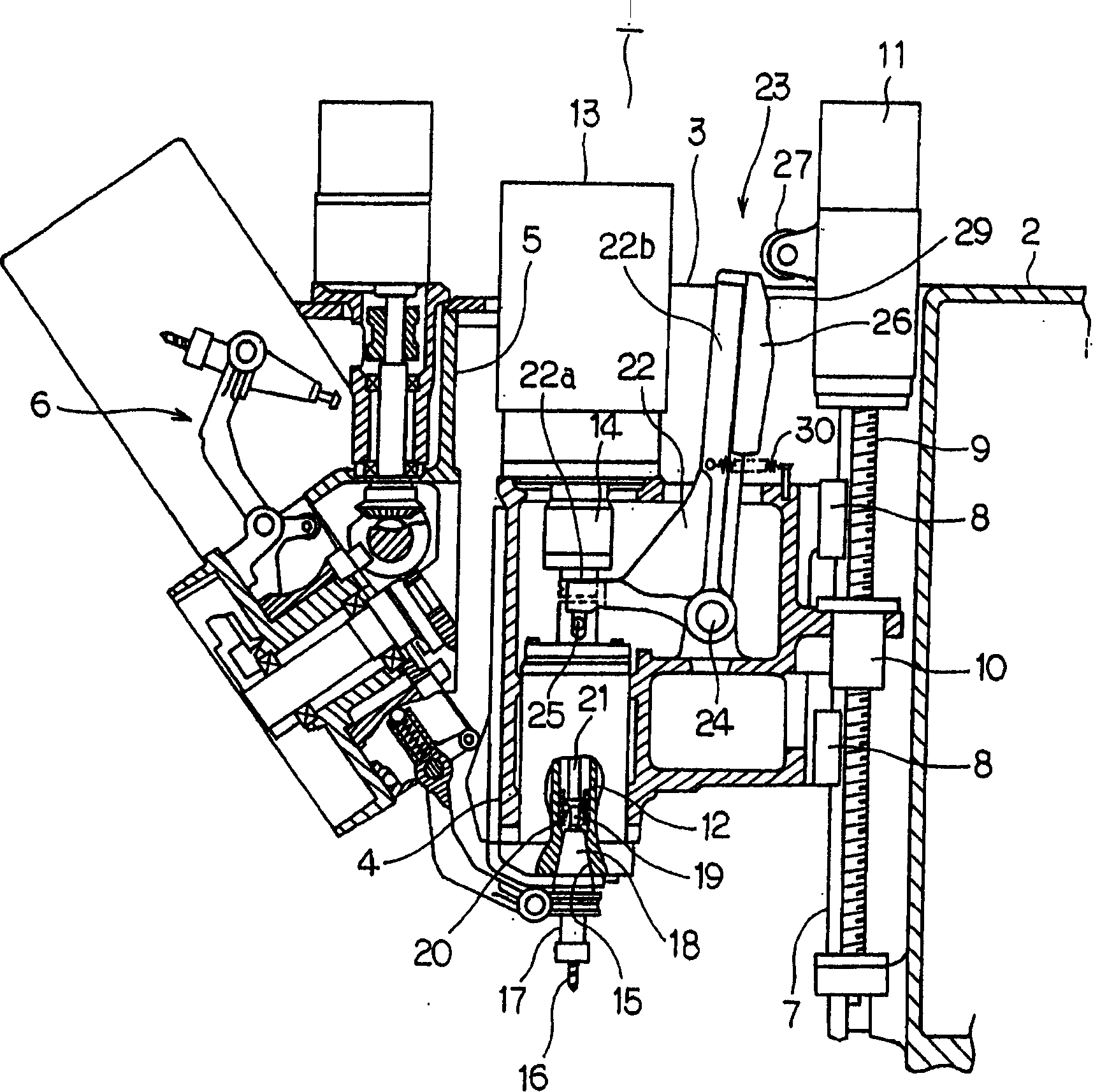

[0015] Refer below Figure 1 ~ Figure 3 The first embodiment of the present invention will be described. first, figure 1 It is a longitudinal sectional view showing a schematic structure of a machine tool to which this embodiment is applied. Such as figure 1 As shown, the machine tool 1 has: a column 2 erected on the base platform (not shown); a frame 3 composed of a box-shaped hollow shell horizontally arranged and fixed on the front surface of the column 2; The main shaft head 4 arranged in the frame 3 ; the rotatable indexing tool box 6 arranged on the frame 3 through the box supporting seat 5 .

[0016] A guide rail 7 is arranged vertically on the column 2 , and a spindle head 4 is provided on the guide rail 7 so as to be able to move up and down (Z-axis) freely via slide blocks 8 , 8 . A rotatable ball screw 9 is provided parallel to the guide rail 7 on the column 2 , and the ball screw 9 is screwed into and passed through a nut 10 fixed on the back of the spindle hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com