Glass cone for cathode-ray tube

A technology for cathode ray tubes, which is applied to the sealing end of the angular deflection coil part, can solve the problems of deterioration of appearance and appearance around the welded part, inconsistent shape, and inability to weld, etc., and achieves suppression of appearance and appearance. Welded state, effect of thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

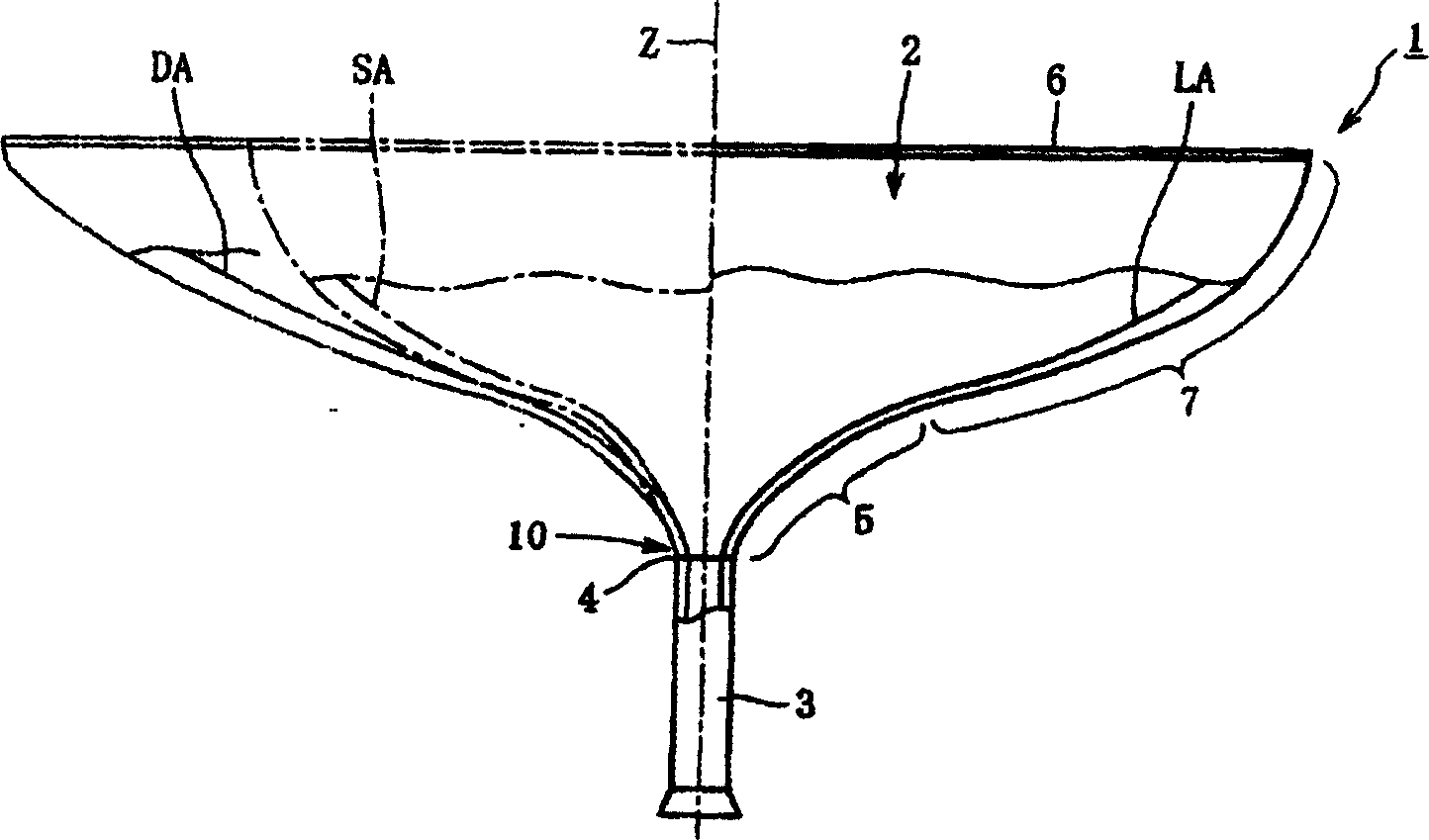

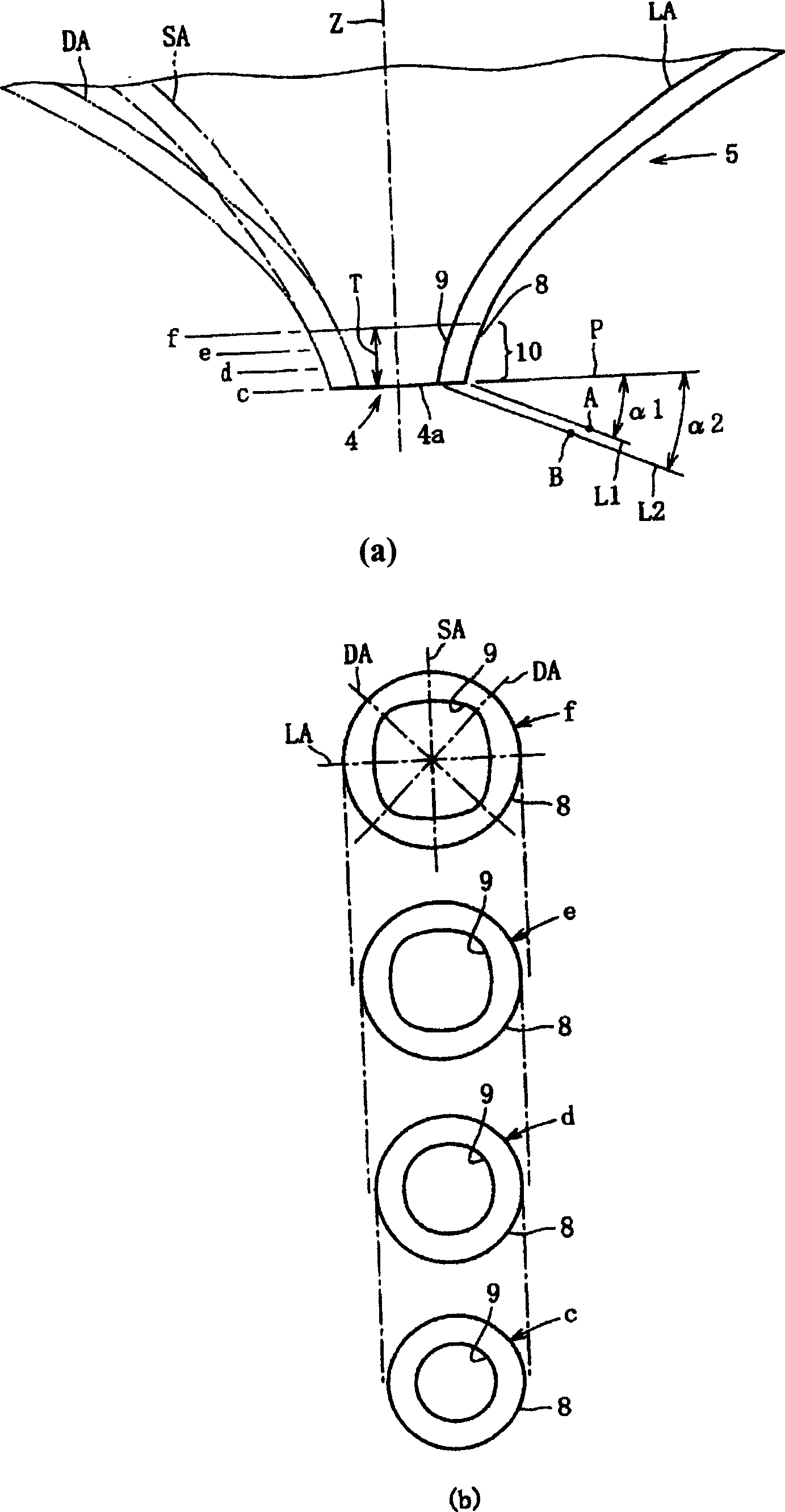

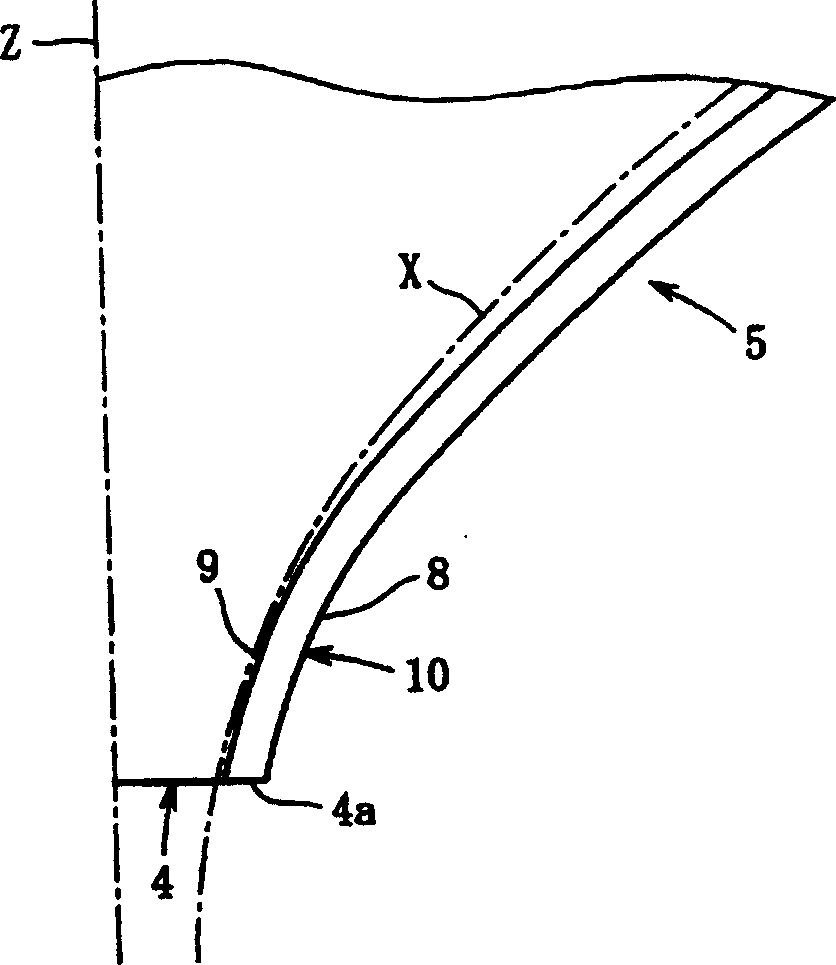

[0056] Embodiments of the present invention will be described below with reference to the attached drawings. In addition, the basic structure of the glass funnel for a cathode ray tube according to the embodiment of the present invention is different from that of the known Figure 6 The same as the existing example shown, so in the following description and each figure referred to in the description, the same as Figure 6 Components that are common to the shown conventional examples are denoted by the same symbols and their detailed descriptions are omitted.

[0057] figure 1 Shown is a front view showing a main part of the glass funnel for a cathode ray tube according to the first embodiment of the present invention. In addition, in the same figure, the section indicated by symbol SA (the section indicated by the dotted line) shows the section including the minor axis SA and the pipe axis Z, and the section indicated by the symbol LA (the section indicated by the solid line)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com