Optical fiber connector disassembling tool

A technology for optical fiber connectors and disassembly tools, which is applied in the direction of optical fiber/cable installation, optics, light guides, etc., and can solve the problems that no one has raised about optical fiber connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

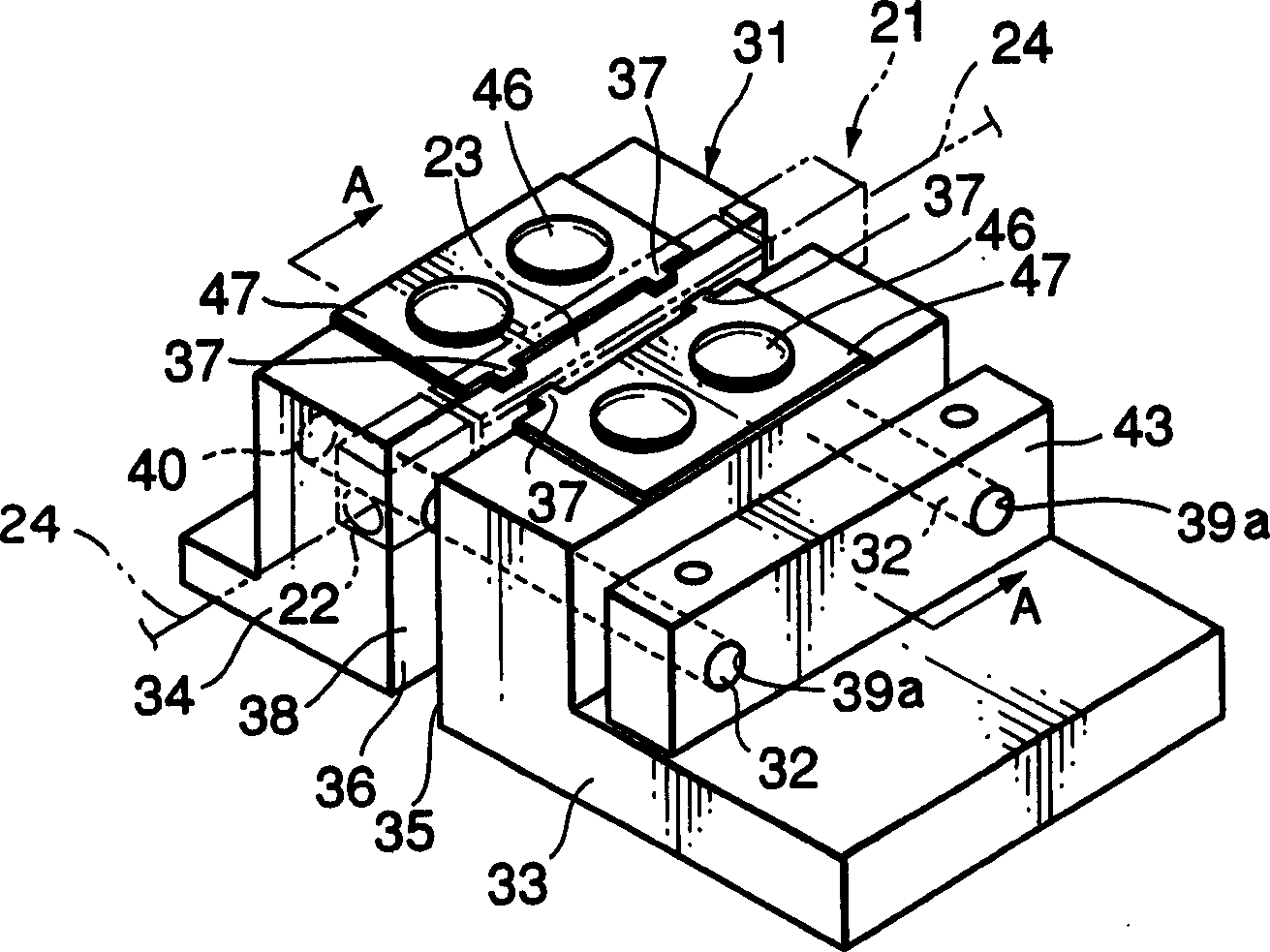

[0038] Refer to the following Figure 6-16 A fiber optic connector removal tool according to one embodiment of the present invention is described.

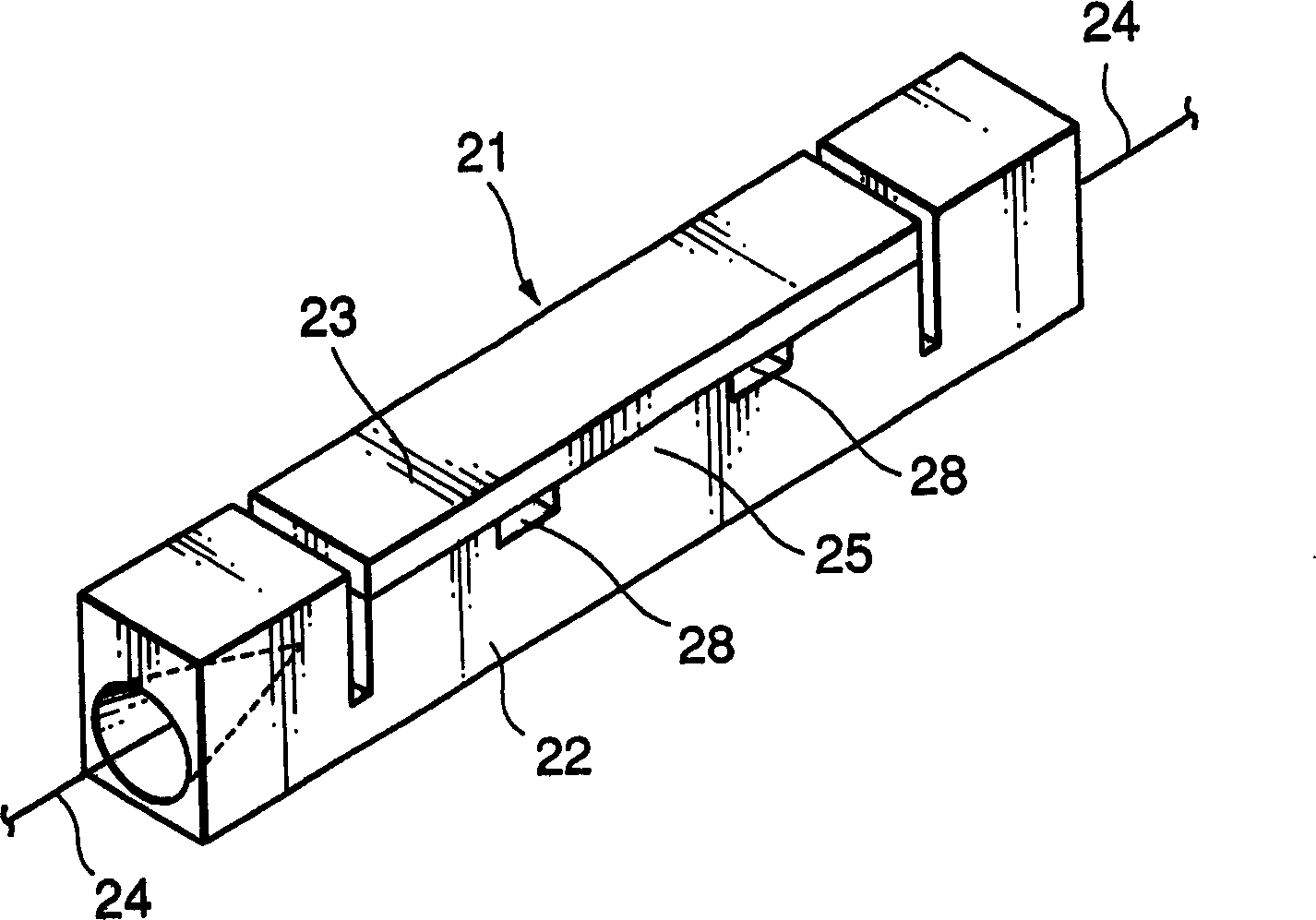

[0039] Figure 6 The perspective view of FIG. 2 shows a removal tool 1 and a plug connector (ie, an optical fiber connector) 11 to be removed by the removal tool 1 .

[0040] The removal tool 1 includes a rectangular plate-shaped body part 2, a holding block 3 fixed to the body part 2, a rail 2a provided on the surface of the body part 2, a slider 4 slidably movable on the rail 2a, and a block for sliding the slider. 4 of the operation part 5.

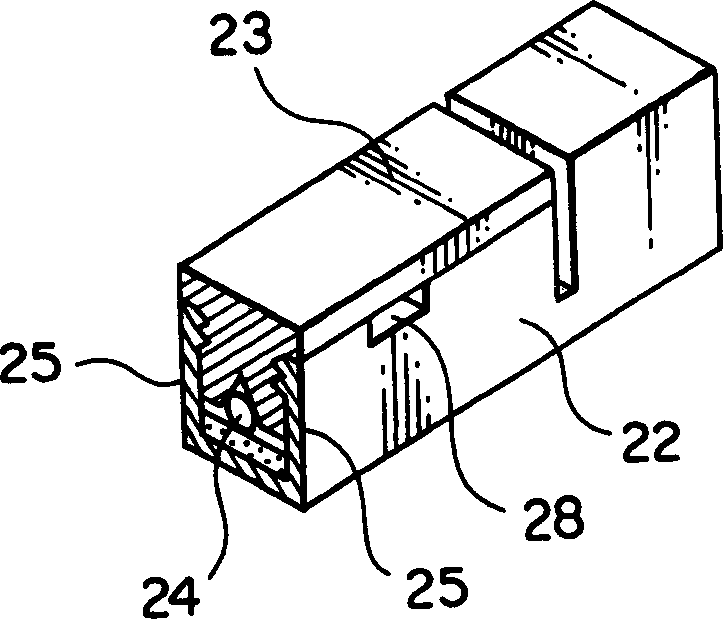

[0041] A pair of rectangular plates 3a, 3a are respectively fixed to the upper surface of the holding block 3 with two pairs of screws 3b, 3b. The intermediate space between the pair of plates 3 a , 3 a is a housing part 3 c for accommodating the plug connector 11 . A curved guide plate 3 d for guiding a cord connected to the plug connector 11 is fixed at the center of one side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com