Button switch

A switch and button technology, applied in electric switches, key key mechanisms, emergency connections, etc., can solve the problems of deviation in operation amount, hindering the thinning of button switches, and poor operating feeling, and achieve thinning and low cost. , the effect of a good sense of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

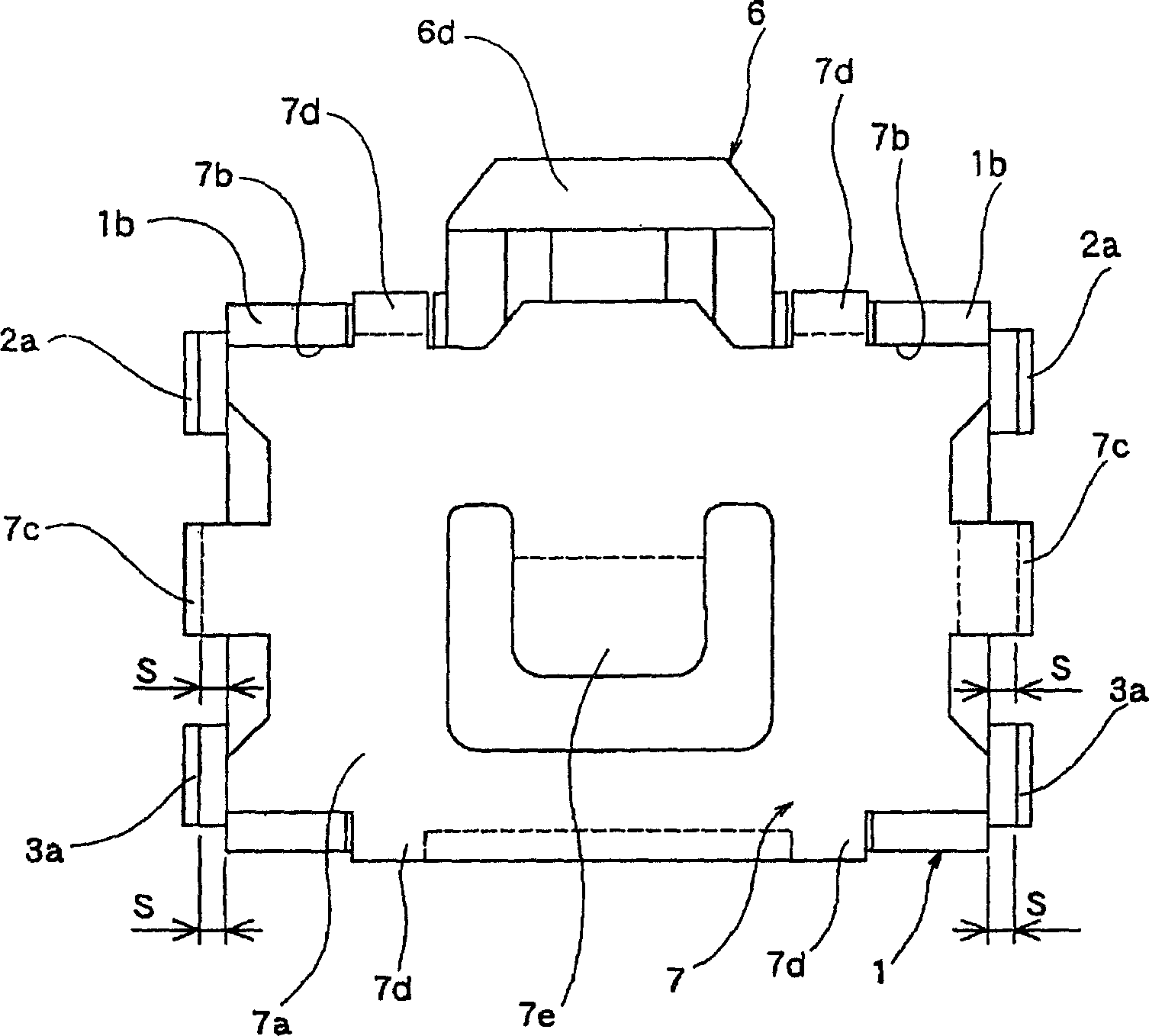

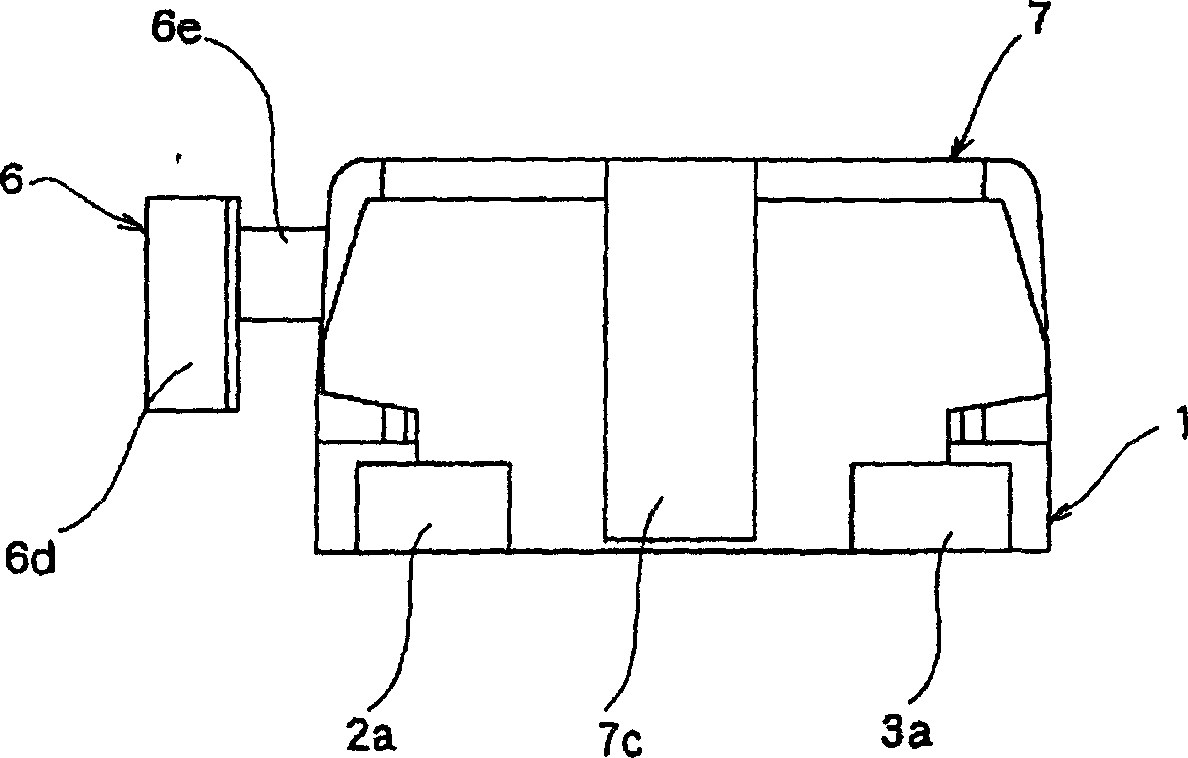

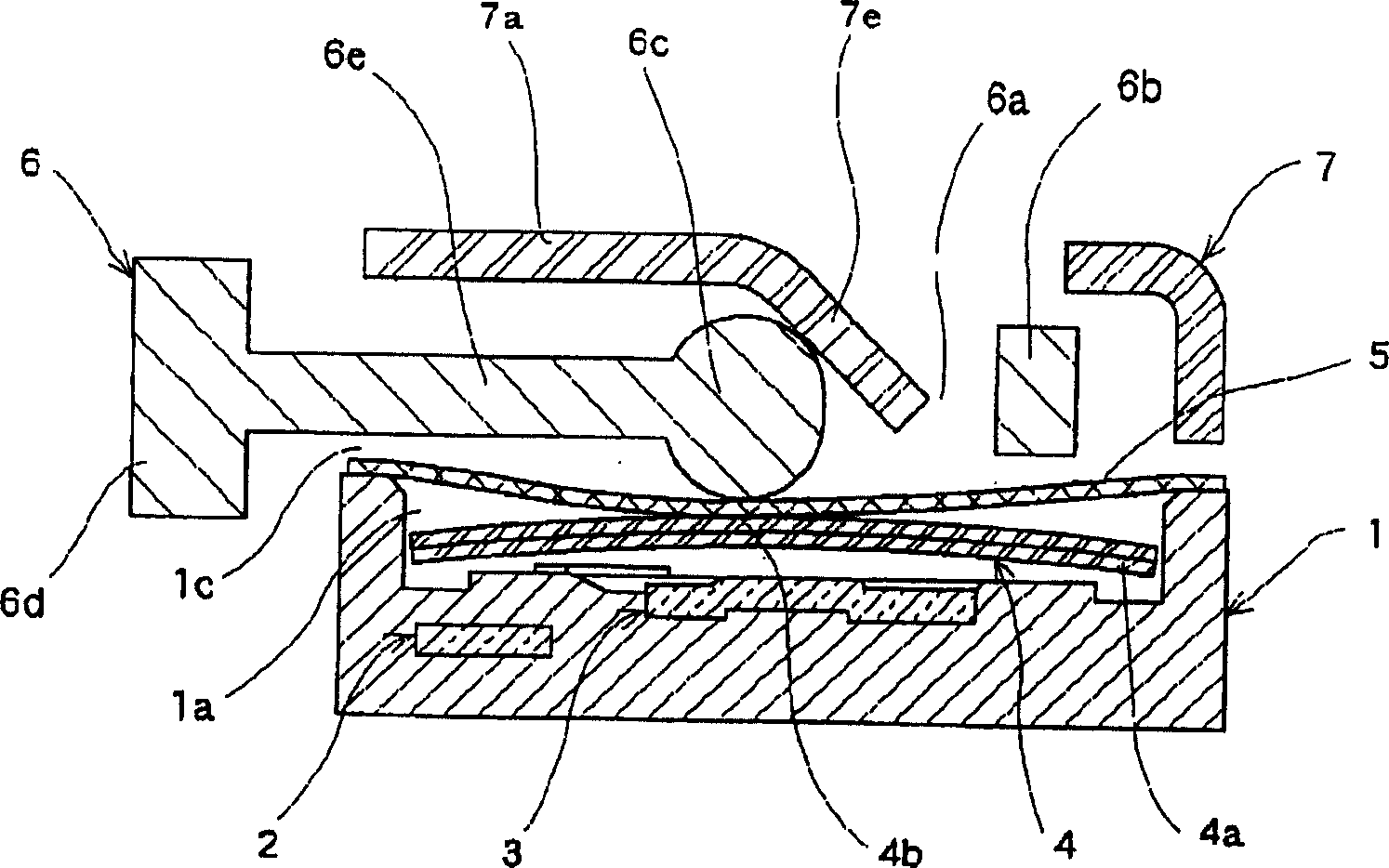

[0041] The embodiment of the button switch of the present invention is shown below in Figure 1 to Figure 9 middle. figure 1 is the top view of the push button switch, figure 2 is the side view of the push button switch, image 3 It is a sectional view of the main part of the push button switch, Figure 4 It is a sectional view of the main part at the time of the push of the push button switch, Figure 5 is the top view of the shell, Image 6 It is a side view showing the state where the pushbutton switch is soldered and mounted on the surface mount substrate, Figure 7 It is a side view showing the state where the leg of the cover is widened and soldered, Figure 8 It is a plan view showing the state in which the ribs are formed on the cover body, Figure 9 It is a side view which shows that the locking part is provided in the leg part of a cover.

[0042] like Figure 1 to Figure 3 and Figure 5 As shown, the push button switch of this embodiment consists of a hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com