Roller control switch

A technology for controlling switches and rollers, applied in electrical switches, electrical components, circuits, etc., can solve the problems of increasing the possibility of rollers, accidental triggering, inconvenient operation, etc., to reduce the possibility of false triggering, obvious operation feeling, and processing handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

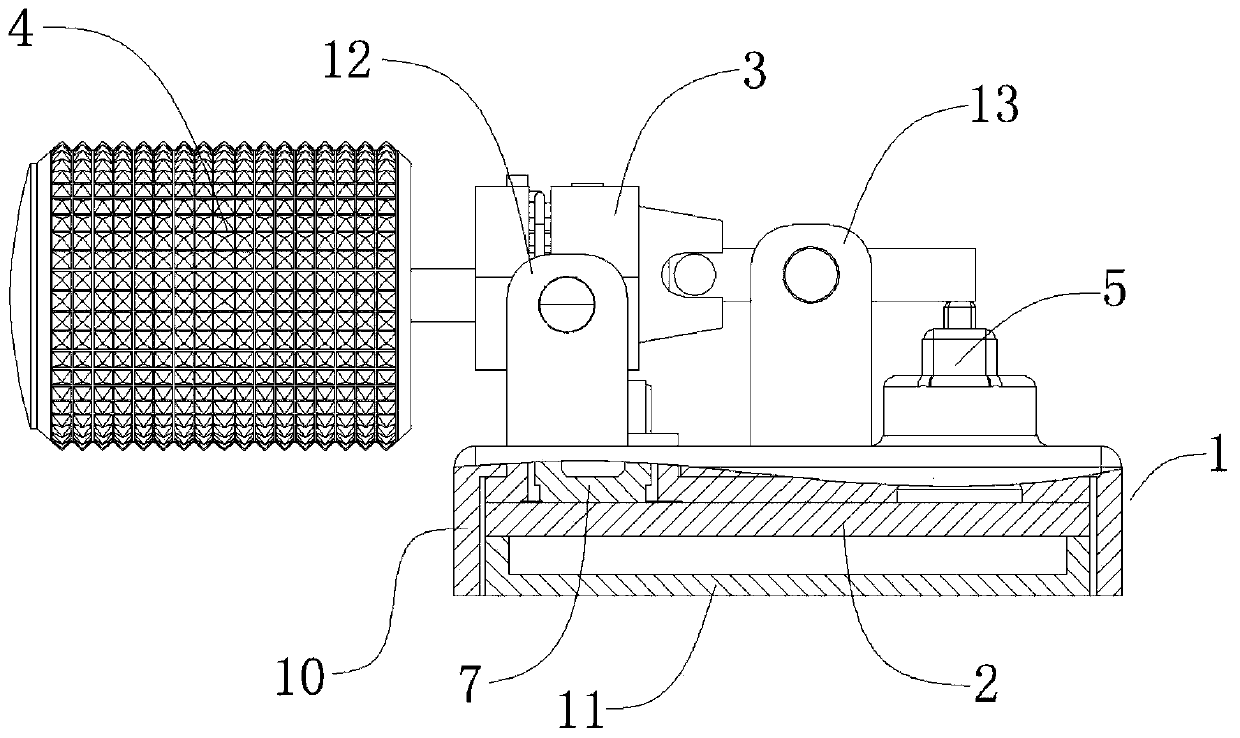

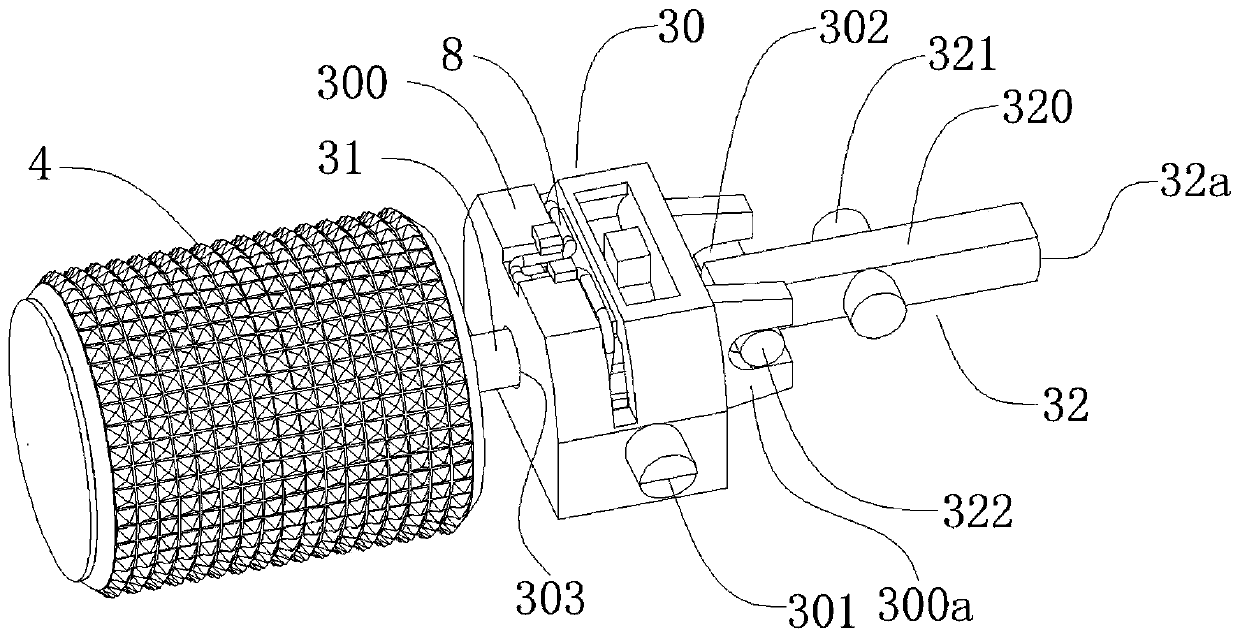

[0035] like figure 1 As shown, the roller control switch corresponding to a preferred embodiment of the present invention includes a base 1, and the base 1 includes an upper shell 10 and a lower shell 11 that are snap-fitted to each other. The circuit board 2 between the housing 10 and the lower housing 11.

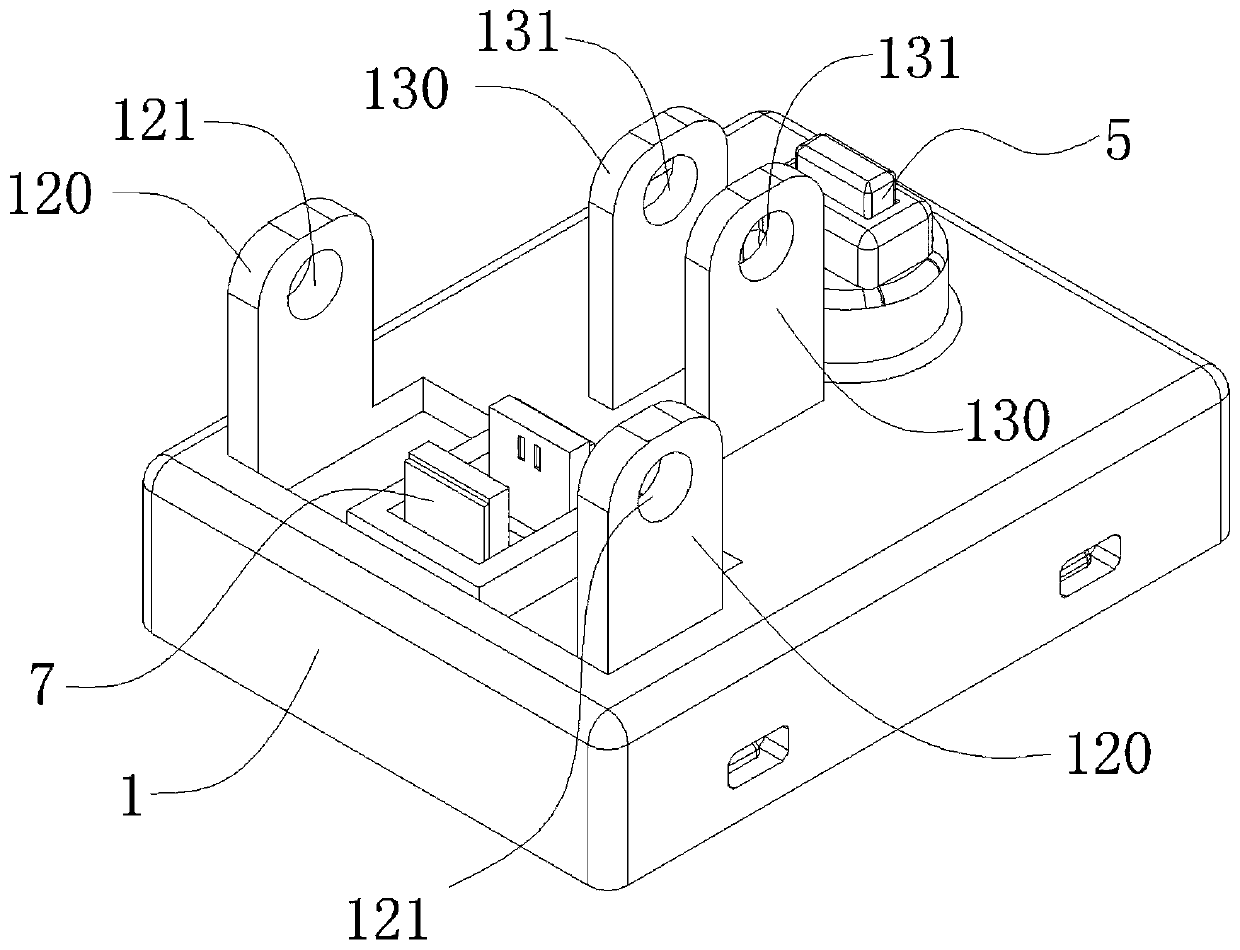

[0036] The base 1 is also provided with a first rotating shaft frame group 12 and a second rotating shaft frame group 13 protruding upward. further reference figure 2 , the first rotating shaft frame group 12 is provided with two first rotating shaft frames 120 which are arranged oppositely, and the first rotating shaft holes 121 arranged on the same axis are opened on the two first rotating shaft frames 120; the second rotating shaft frame group 13 and the first rotating shaft frame The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com