Ink fountain apparatus for rotary printing press

A printing press and rotary technology, which is applied to the ink fountain device field of rotary printing presses, can solve the problems of high pressure of the pressing device and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

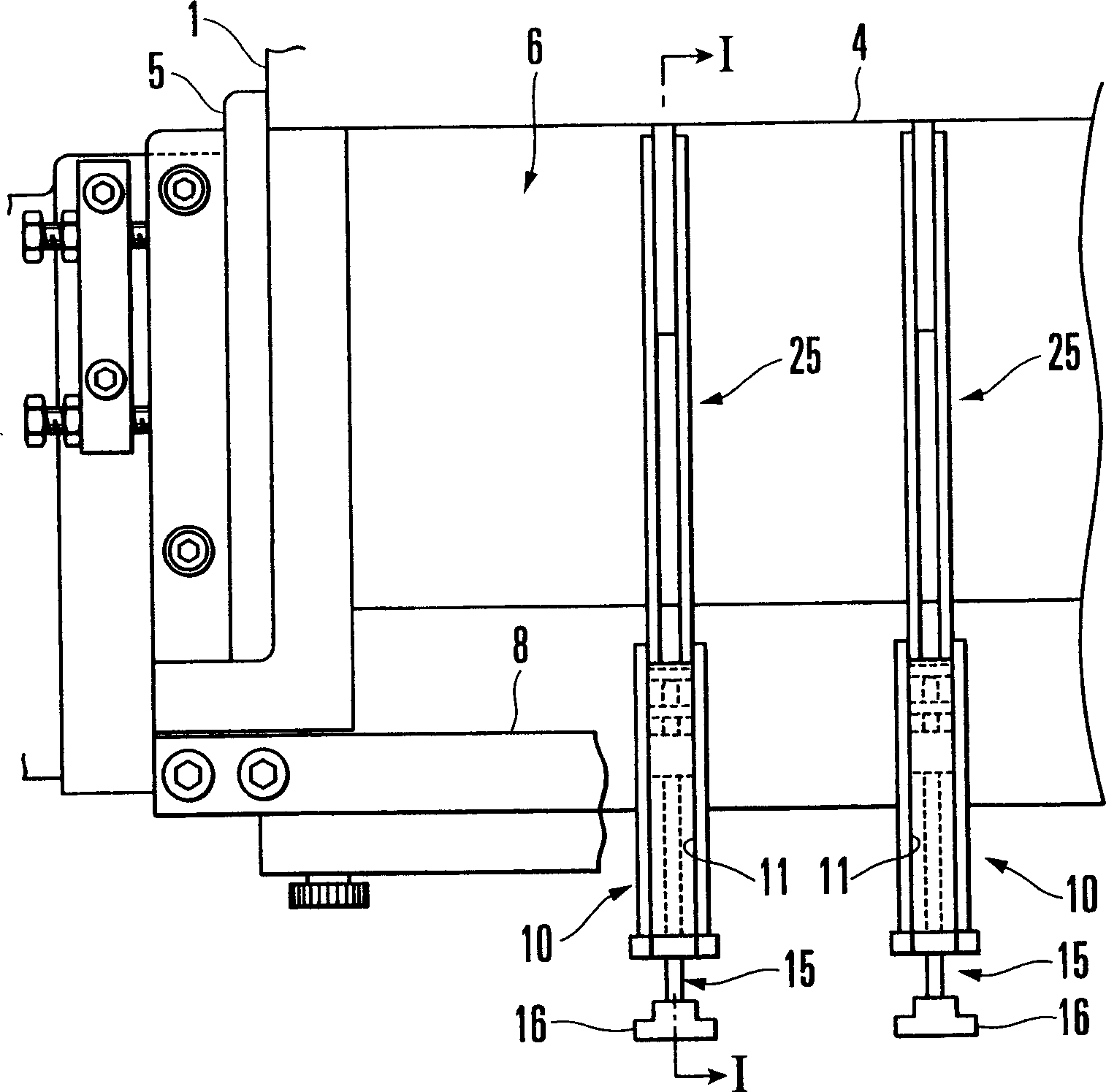

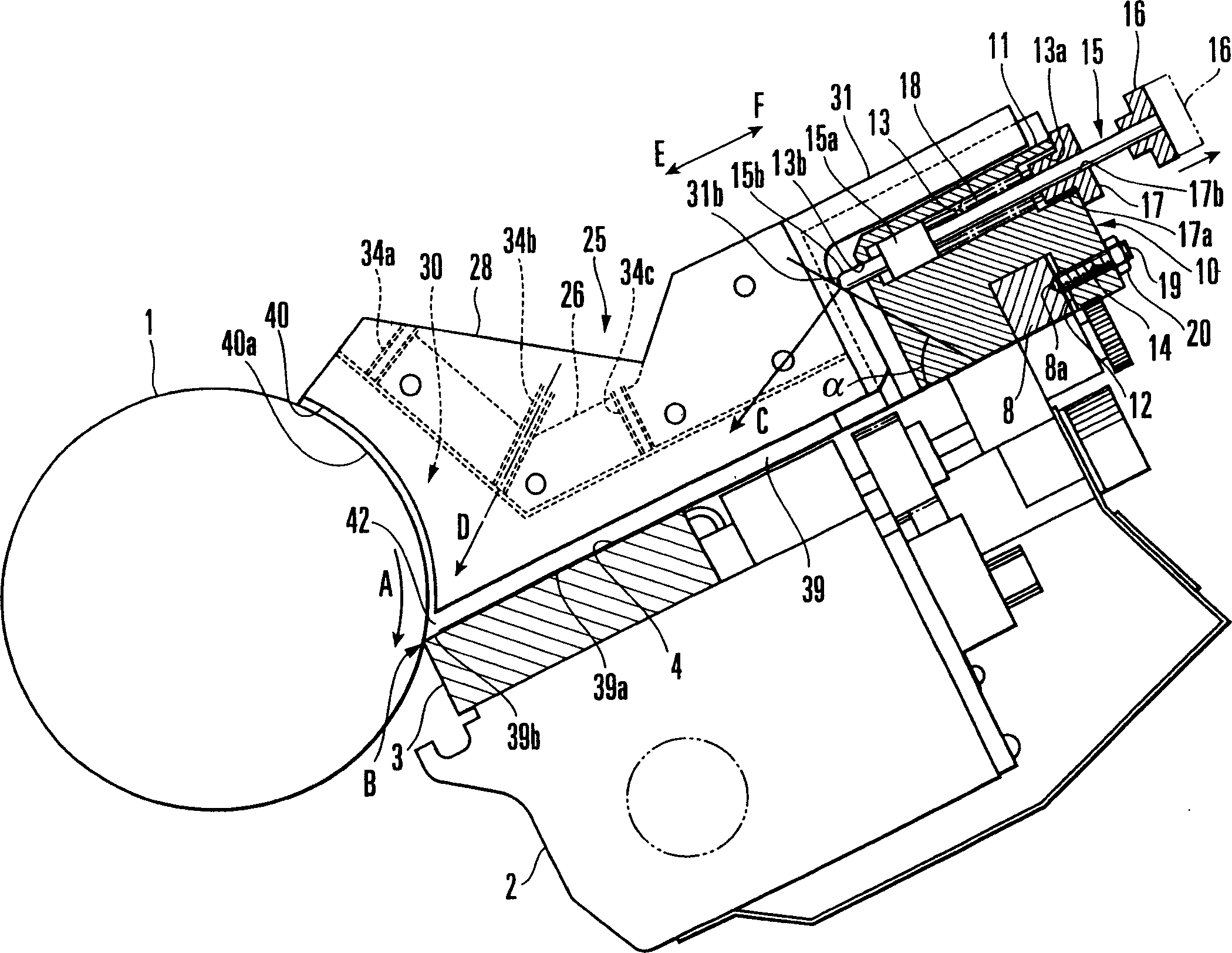

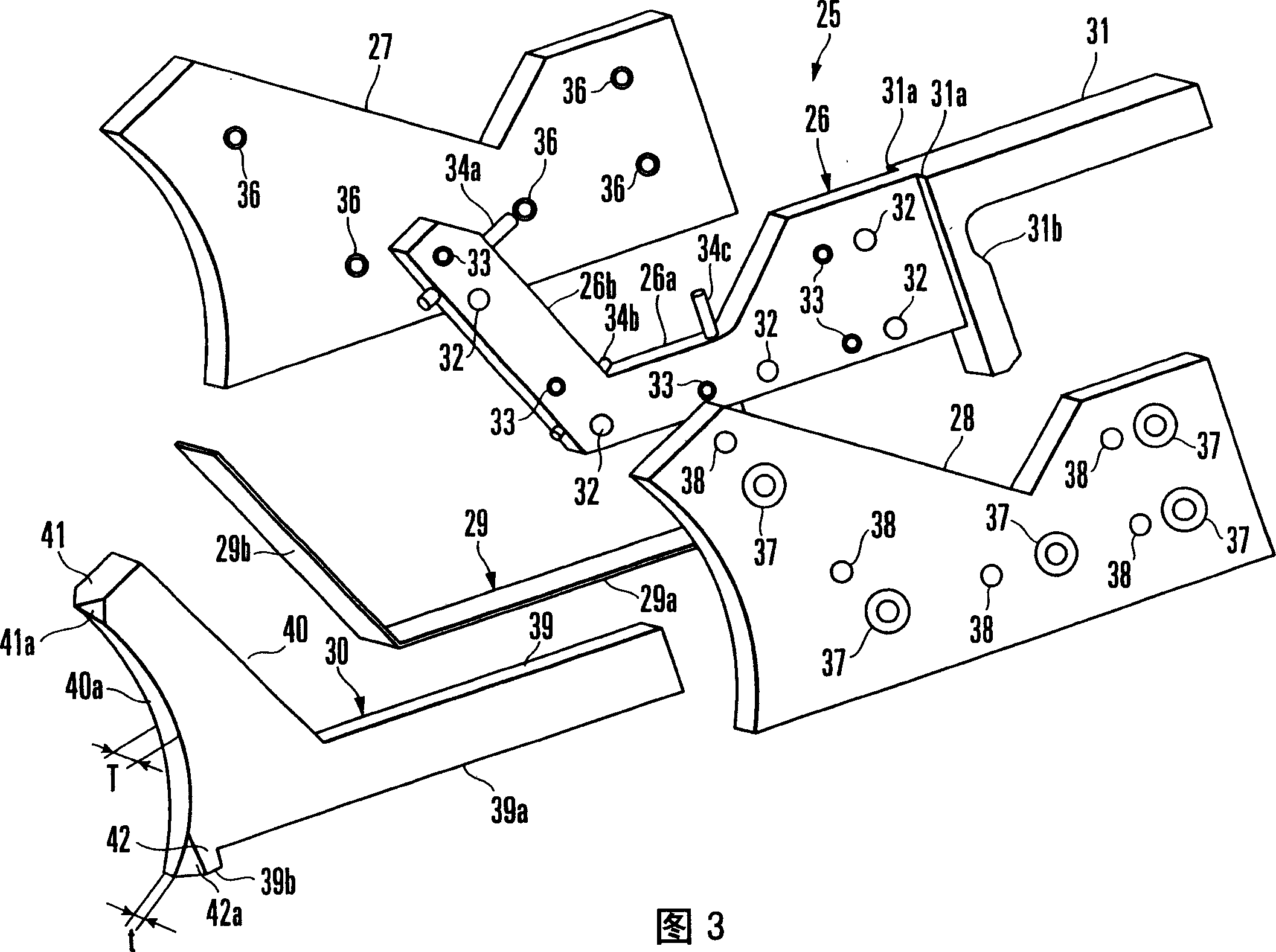

[0017] Refer to attached Figure 1-6 The present invention will be described in detail.

[0018] figure 2 An ink fountain device for a rotary printing press according to an embodiment of the present invention is shown. Refer to attached figure 2 , the ink fountain roller 1 rotatable in the direction shown by arrow A extends axially between a pair of frames (not shown) which are arranged to face each other through a predetermined distance, and the doctor blade base 2 is arranged on the ink fountain roller 1 so that its ends are supported by the pair of racks. A large number of fountain keys 3 divided in the axial direction of the fountain roller 1 are placed on an inclined surface at the upper end of the doctor blade base 2 . When a motor (not shown) is driven, the aperture ratio of the distal end or tip of the ink fountain key 3 is adjusted in various directions to approach and move away from the outer surface of the ink fountain roller 1 .

[0019] An ink fountain blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com