Alginate capsule immobilized with cell and preparation method thereof

An alginate and capsule technology, applied in directions such as being fixed on/in an organic carrier, can solve the problems of high preparation cost, complicated process, affecting solute diffusion, etc., and achieves low price, good biocompatibility, and good The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

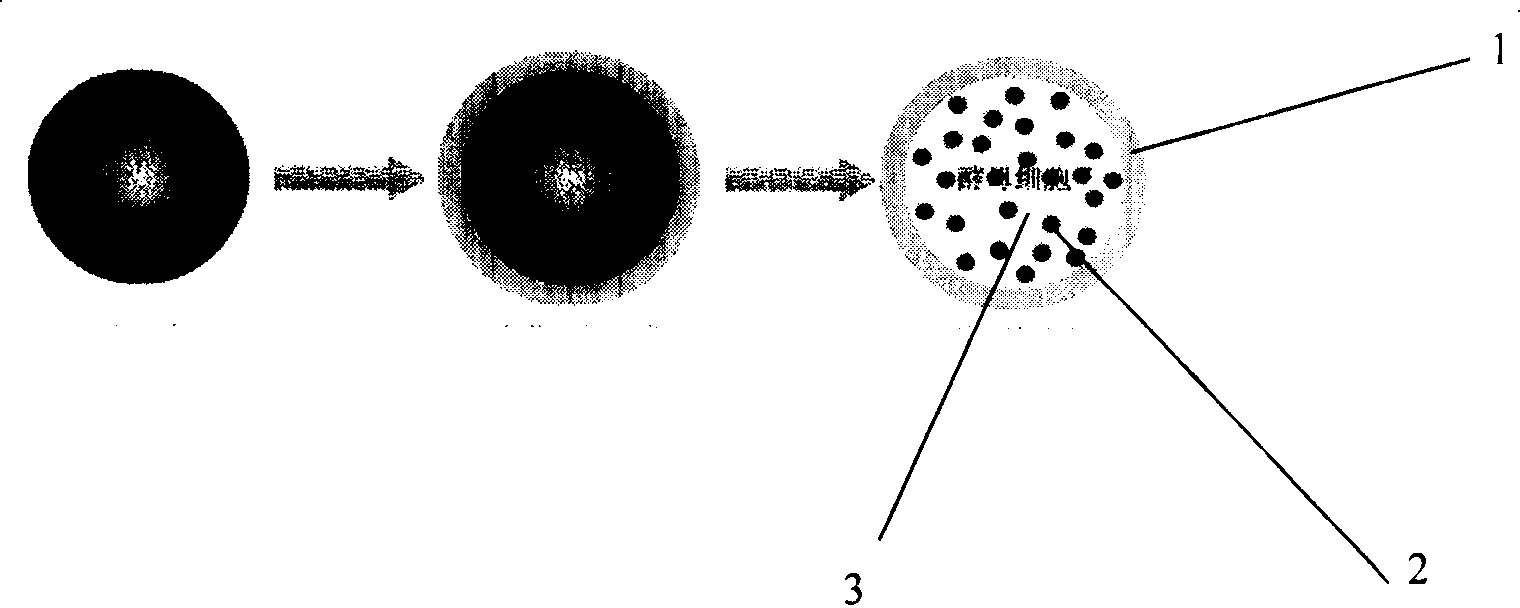

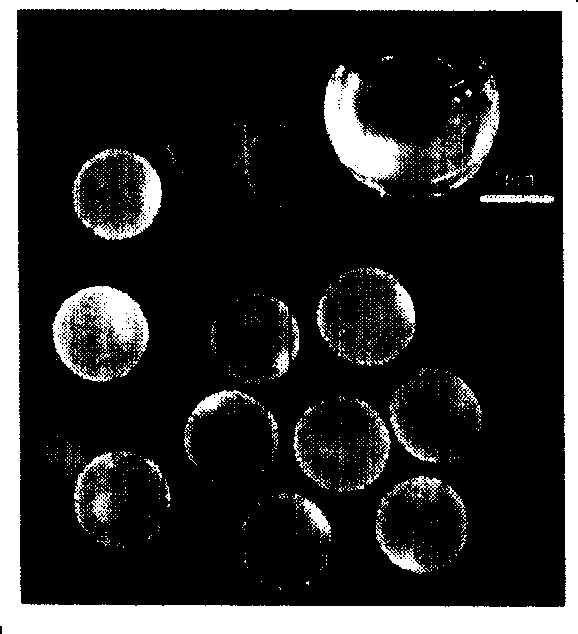

[0028] Example 1, preparation of calcium alginate capsules immobilized with yeast cells

[0029] The yeast in the logarithmic growth phase of the suspension culture is centrifuged to collect the thalline, and at 37 ° C with gelatin-calcium chloride solution (making the gelatin concentration after mixing is 15% (wt %), the calcium chloride concentration is 0.1mol / L ) and mix evenly, then drop into low-temperature hydroxy silicone oil (5°C), and cool for ten minutes to form a gelatin pellet with a particle size of 2.5-3.0mm, then add 0.5% (wt%) alginic acid to the pellet under stirring Film-forming reaction in sodium solution for 90 seconds, then filter out with a sieve, and continue to react in 0.1mol / L calcium chloride solution for 10 minutes under stirring to enhance the strength of the capsule membrane. Finally, filter with a sieve, wash three times with Tris buffer, and treat at a constant temperature of 37°C in Tris buffer to obtain calcium alginate encapsulated yeast (suc...

Embodiment 2

[0032] Example 2, preparation of calcium alginate capsules immobilized with Escherichia coli

[0033]Escherichia coli (E.coli JM109 (pKST11)) in the logarithmic growth phase of the suspension culture was centrifuged to collect the thalline, and mixed with gelatin-calcium chloride solution (so that the gelatin concentration after mixing was 25% (wt %), Calcium chloride concentration is 0.1mol / L) and mixed evenly, drop into low-temperature hydroxyl silicone oil (10°C), and cool for ten minutes to form gelatin balls with a particle size of 3.5-4.0mm, and then add the balls to 1.5 % (wt%) sodium alginate solution for film-forming reaction for 120 seconds, then filter out with a sieve, and continue to react in 0.1mol / L calcium chloride solution for 10 minutes under stirring to enhance the strength of the capsule membrane. Finally, it was filtered with a sieve, washed three times with Tris buffer, and treated at a constant temperature of 37°C in Tris buffer to obtain Escherichia col...

Embodiment 3

[0035] Example 3, preparation of alginate capsules immobilized with yeast cells

[0036] The yeast in the logarithmic growth phase of the suspension culture was centrifuged to collect the thalline, and mixed with gelatin-barium chloride solution (making the gelatin concentration 5% (wt%) and barium chloride concentration 0.05mol / L after mixing) at 37°C Mix evenly, drop into low-temperature liquid paraffin (2°C), and cool for ten minutes to form gelatin pellets with a particle size of 1.0-1.5mm, and then add the pellets to 0.5% (wt%) sodium alginate solution under stirring Film-forming reaction for 40 seconds, then filter out with a sieve, and continue to react in 0.05mol / L barium chloride solution for 10 minutes under stirring, so as to enhance the strength of the capsule membrane. Finally, it was filtered through a sieve, washed three times with acetate buffer, and treated at a constant temperature of 25°C in acetate buffer to obtain barium alginate-encapsulated yeast.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com