Air outlet assembly for a vehicle

A technology for ventilation outlets and motor vehicles, which is applied to vehicle components, heating/cooling equipment, transportation and packaging, etc., and can solve problems such as susceptibility to interference, high cost, and unstable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

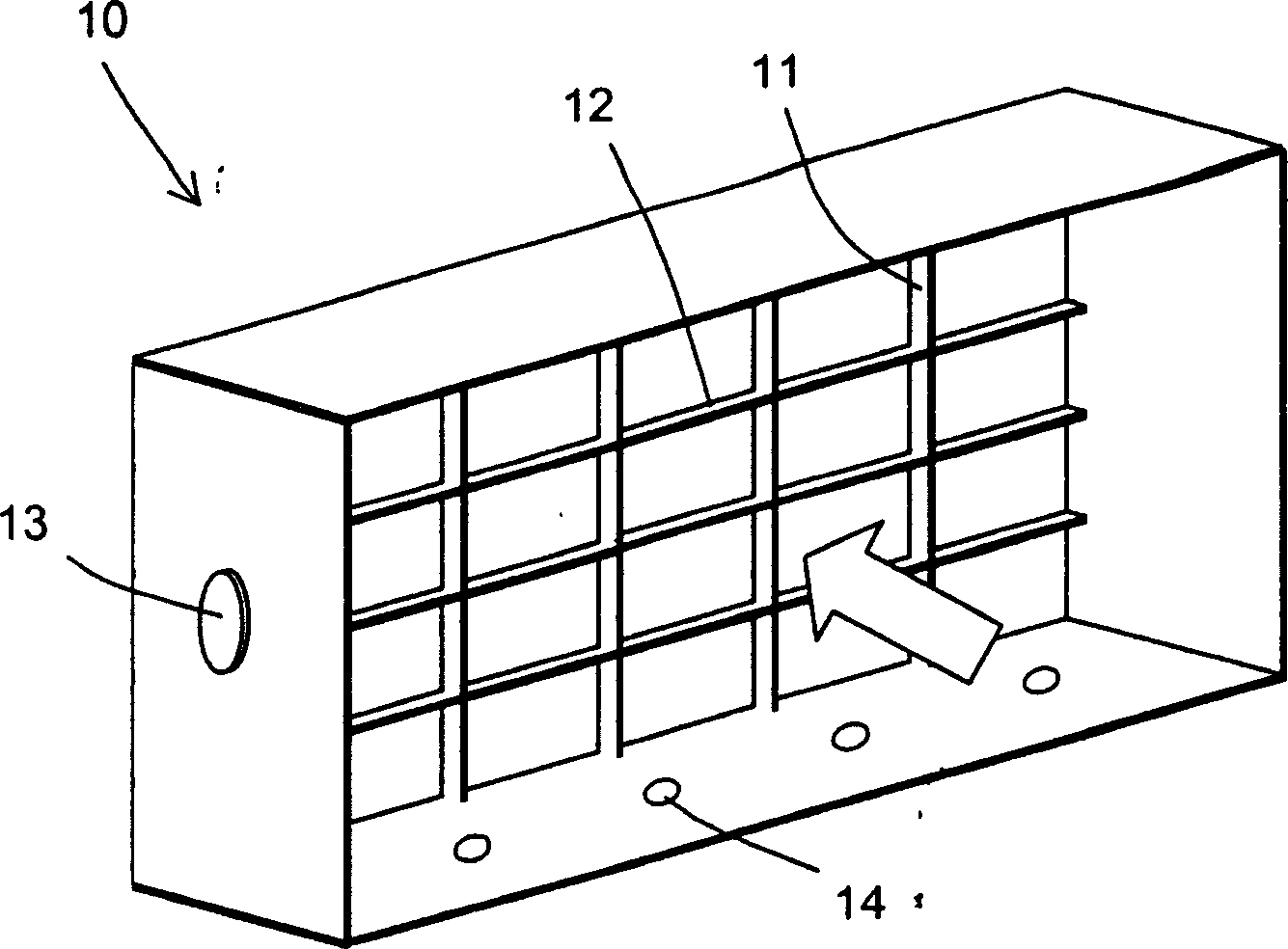

[0027] figure 1 A housing frame 10 according to the invention for an air vent of a motor vehicle is shown schematically. The housing frame 10 is substantially in the shape of a rectangular frame and has an intake side (front) and an exhaust side (rear). The direction of air flow when using the vent is indicated by a boxed arrow. The entire ventilation opening including the housing frame is preferably made of plastic.

[0028] The exhaust side facing the passenger compartment is covered in the example shown by a grid consisting of a plurality of vertical baffles 11 and a plurality of horizontal baffles 12 . These air deflector vanes 11 , 12 can be adjusted in a manner not shown and / or have operating elements such as knobs or sliding elements, by means of which components (guide vanes, slots) to be described below can be moved.

[0029] Also in figure 1 One of the two hinge pins 13 opposite to each other can be seen in the drawing, by means of which the housing frame 10 as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com