End plate for heat exchangers, heat exchanger having the same, and manufacturing method thereof

A technology of heat exchangers and end plates, which is applied in the manufacture of heat exchangers and heat exchangers, and in the field of end plates of heat exchangers, and can solve problems that do not need to be solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Reference will now be made in detail to the illustrative, non-limiting embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like parts. Embodiments of the present invention will be described below with reference to the drawings.

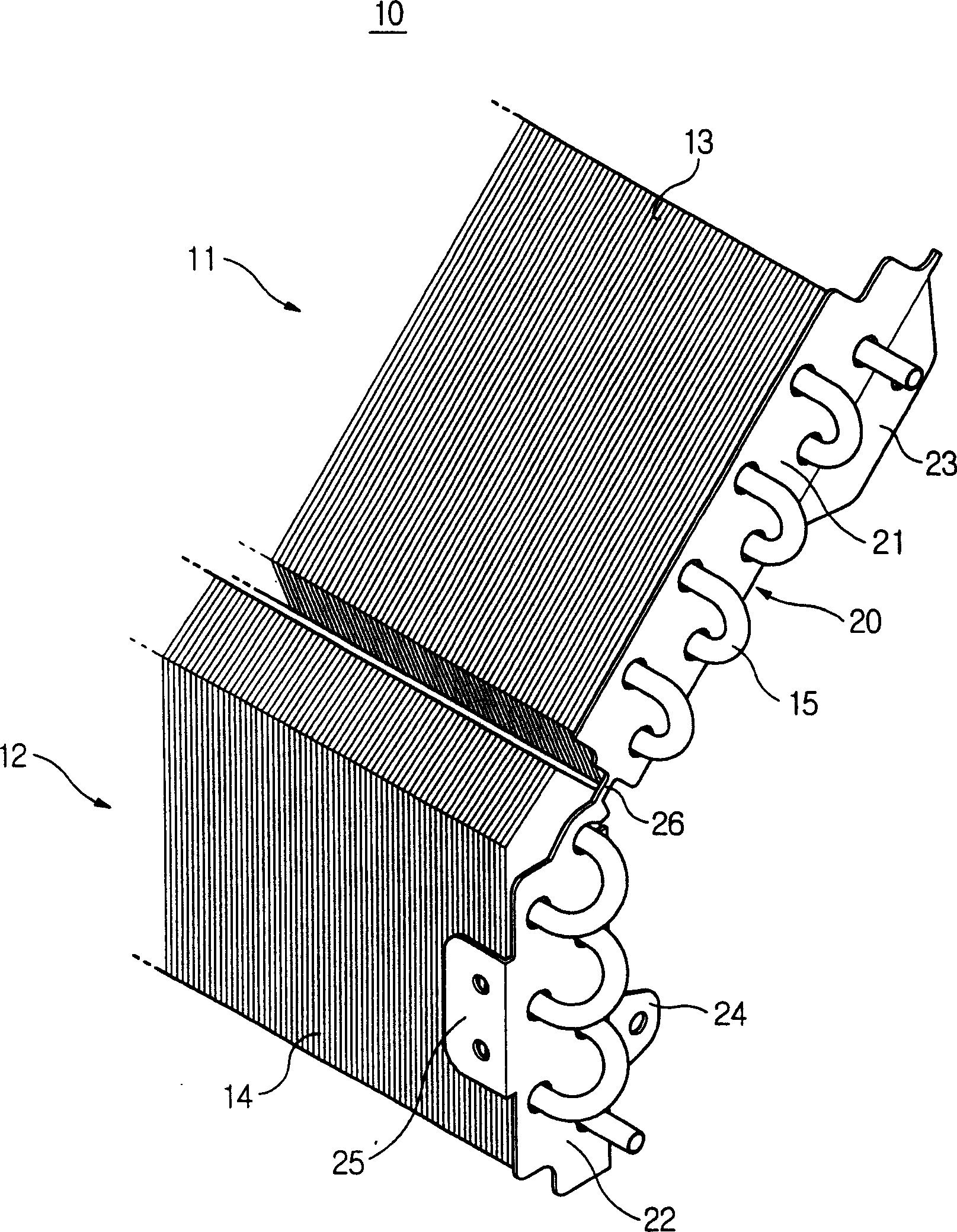

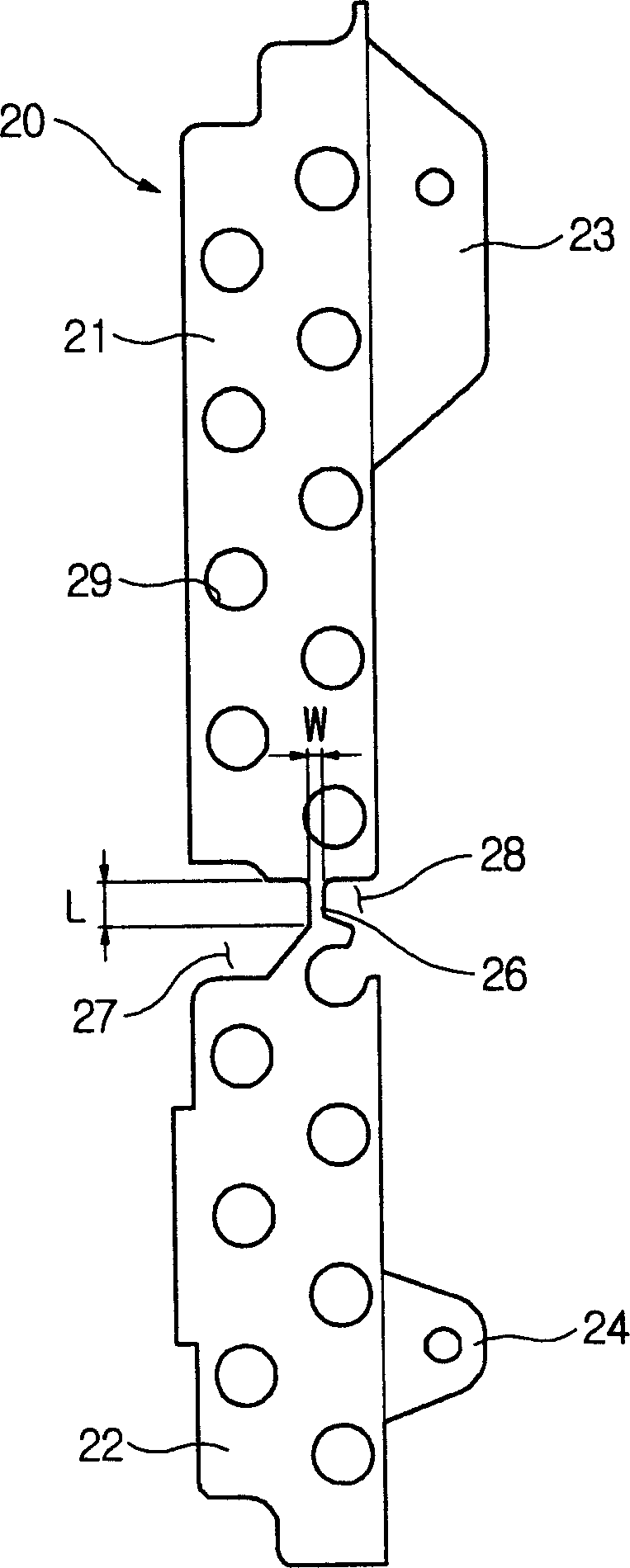

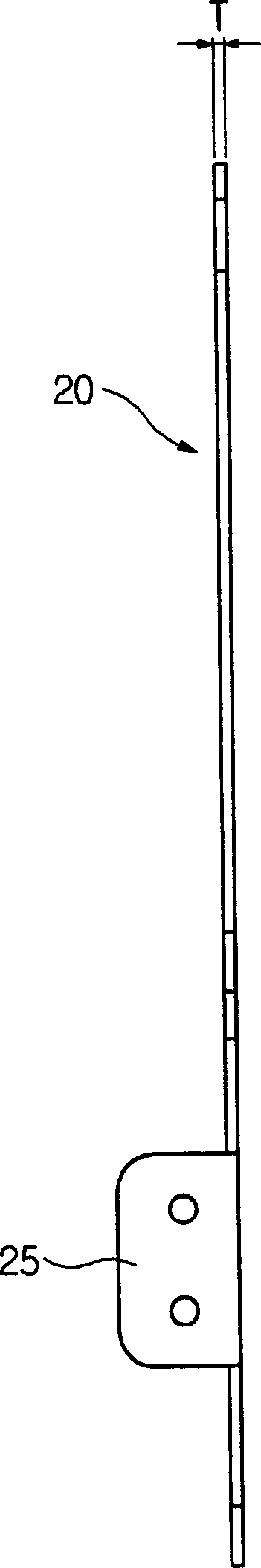

[0029] figure 1 is a perspective view of a heat exchanger according to the present invention. figure 2 yes figure 1 Front view of a heat exchanger with end plates. image 3 yes figure 2 Side view of the end plate.

[0030] Such as figure 1 As shown, the heat exchanger 10 includes a first heat exchange portion 11 located above the horizontal centerline of the heat exchanger 10 and a second heat exchange portion 12 located below the centerline. A plurality of fins are arranged for providing a first fin array 13 of the first heat exchanging portion 11 . Similarly, a plurality of fins are arranged to provide a second fin array 14 of the second heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com