Manned rice transplanter

A rice transplanter and manned technology, which is applied in the field of manned rice transplanters, can solve the problems such as the inability to set turns, the inability to maintain the grounding state of the buoy, and the inability to quickly switch the grounding state of the buoy, so as to achieve the effect of realizing the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

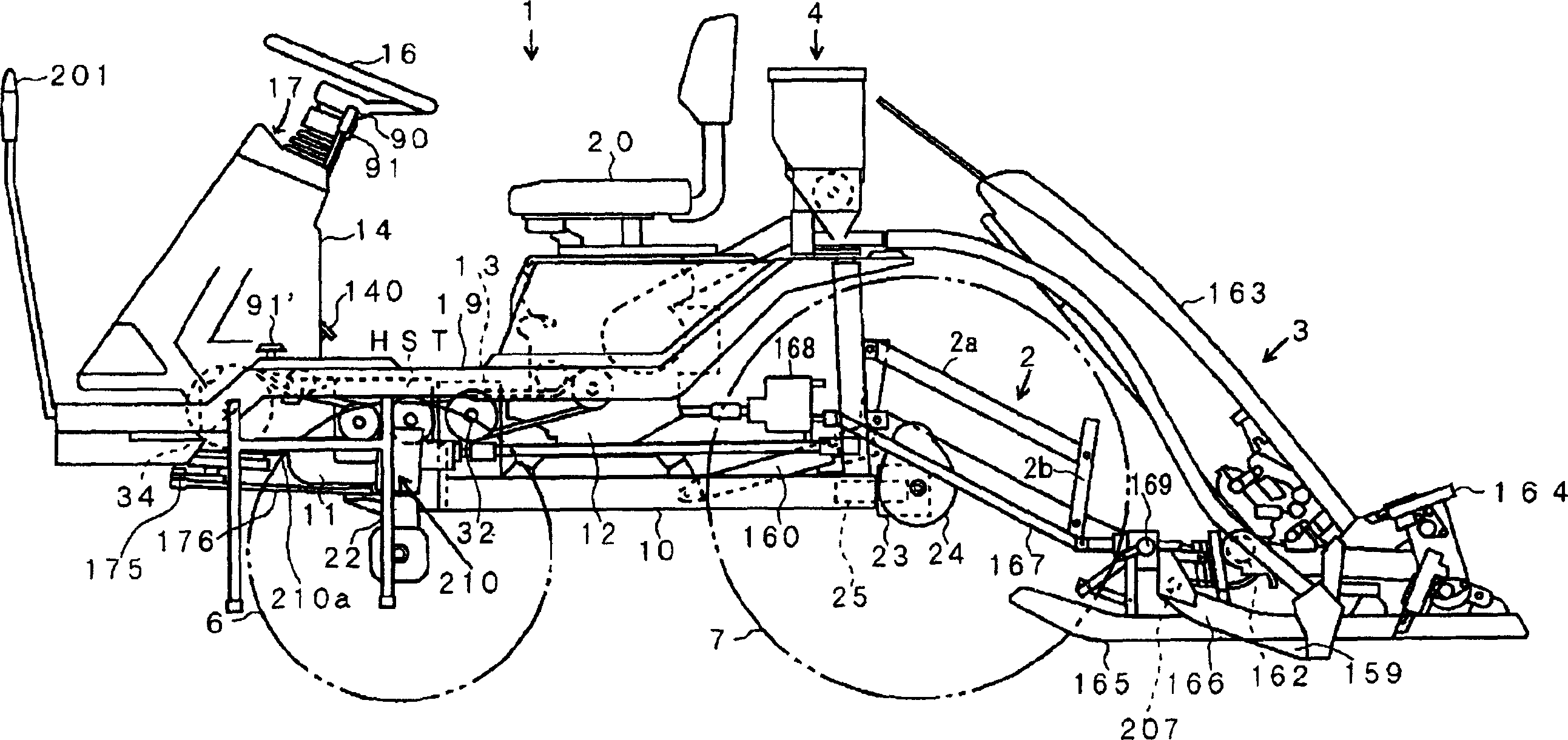

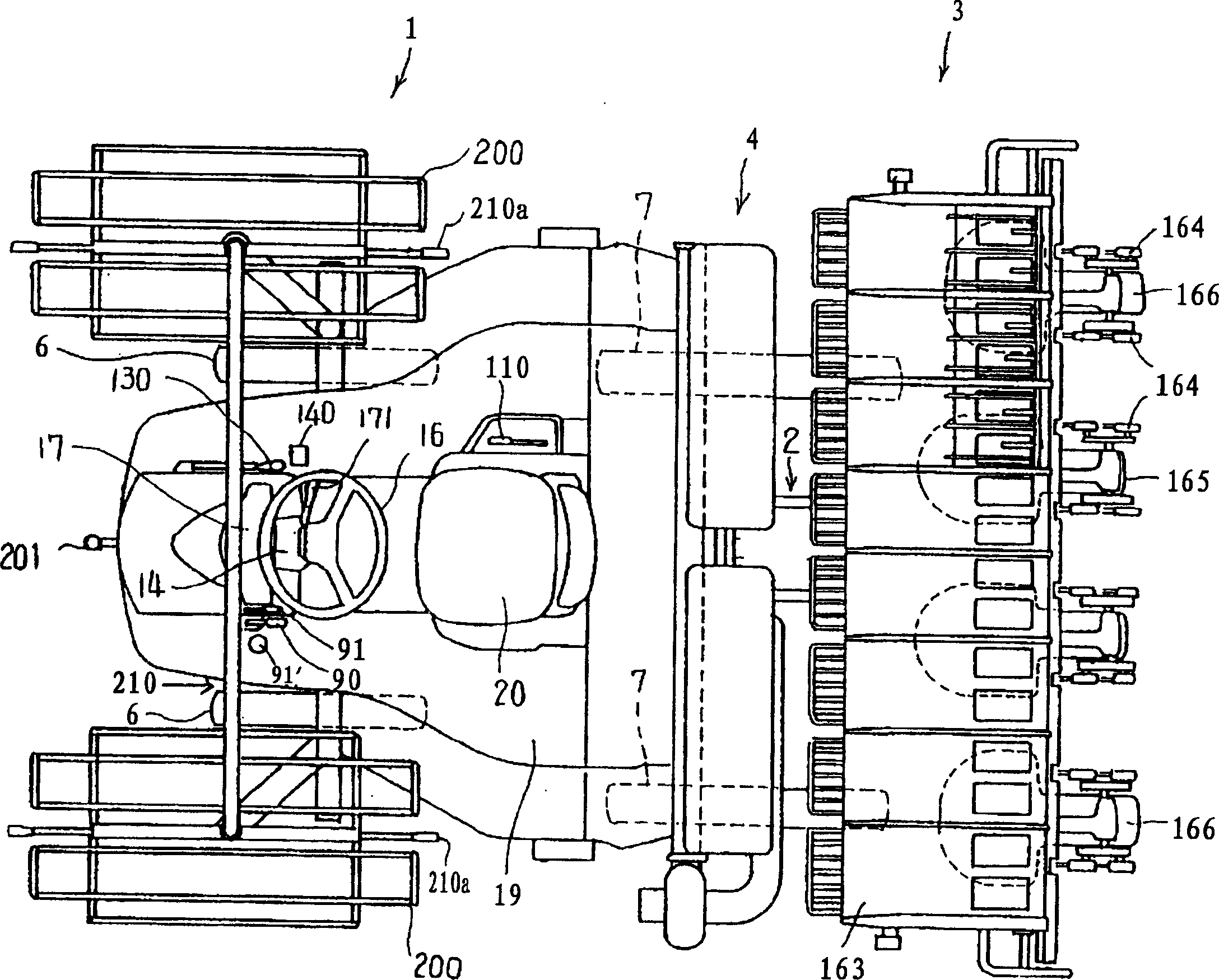

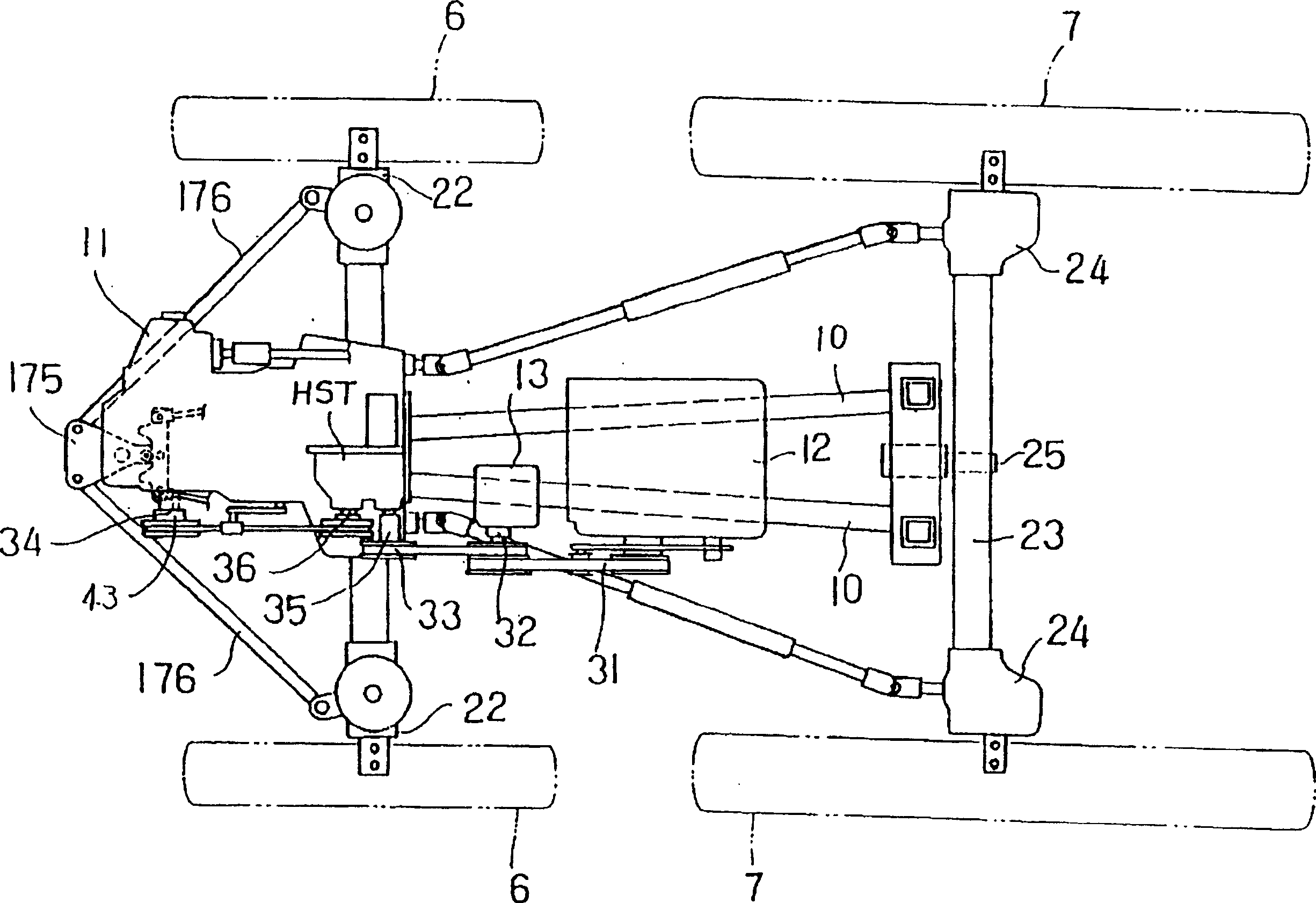

[0027] The 8-row planting manned rice transplanter as an embodiment of the present invention will be described in detail according to the accompanying drawings.

[0028] figure 1 It is an overall side view of the manned rice transplanter of the present invention, figure 2 for the overall floor plan. image 3 to represent figure 1 A schematic plan view of the transmission structure of the walking vehicle of the manned rice transplanter, and Fig. 4 is an expanded sectional view of the gearbox body.

[0029] Such as figure 1 As shown in the side view, the manned rice transplanter uses a lifting link device 2 composed of a horizontal link 2a and a longitudinal link 2b to install a seedling planting device 3 as a working device on a walking vehicle 1. At the same time, A fertilization device 4 is provided, and the whole has the function of carrying manned fertilization and transplanting rice seedlings. The traveling vehicle 1 is a four-wheel drive vehicle having a pair of lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com