Substrate duster

A technology for dust removal devices and substrates, which are used in cleaning methods using tools, electrical components, and printed circuit manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

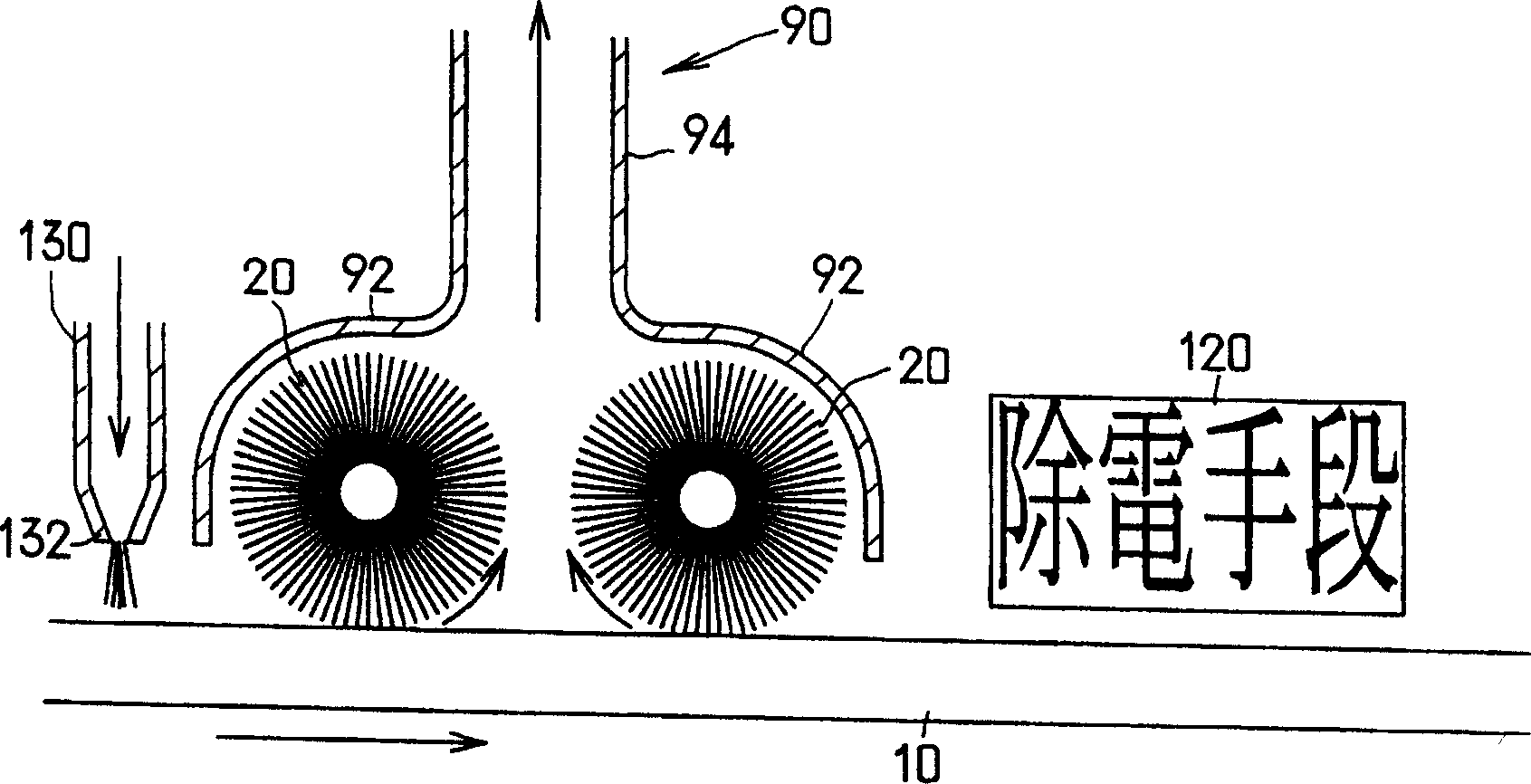

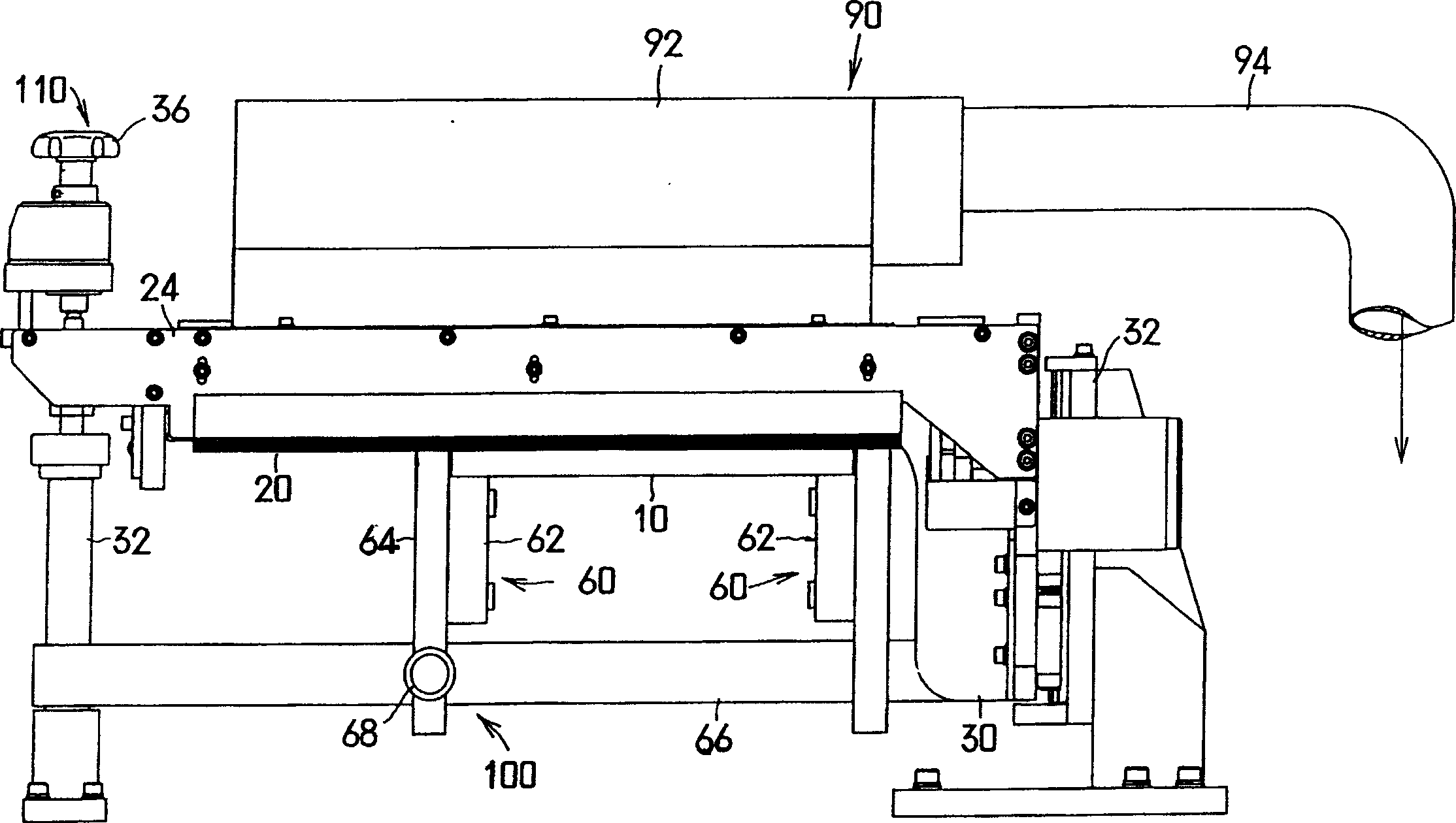

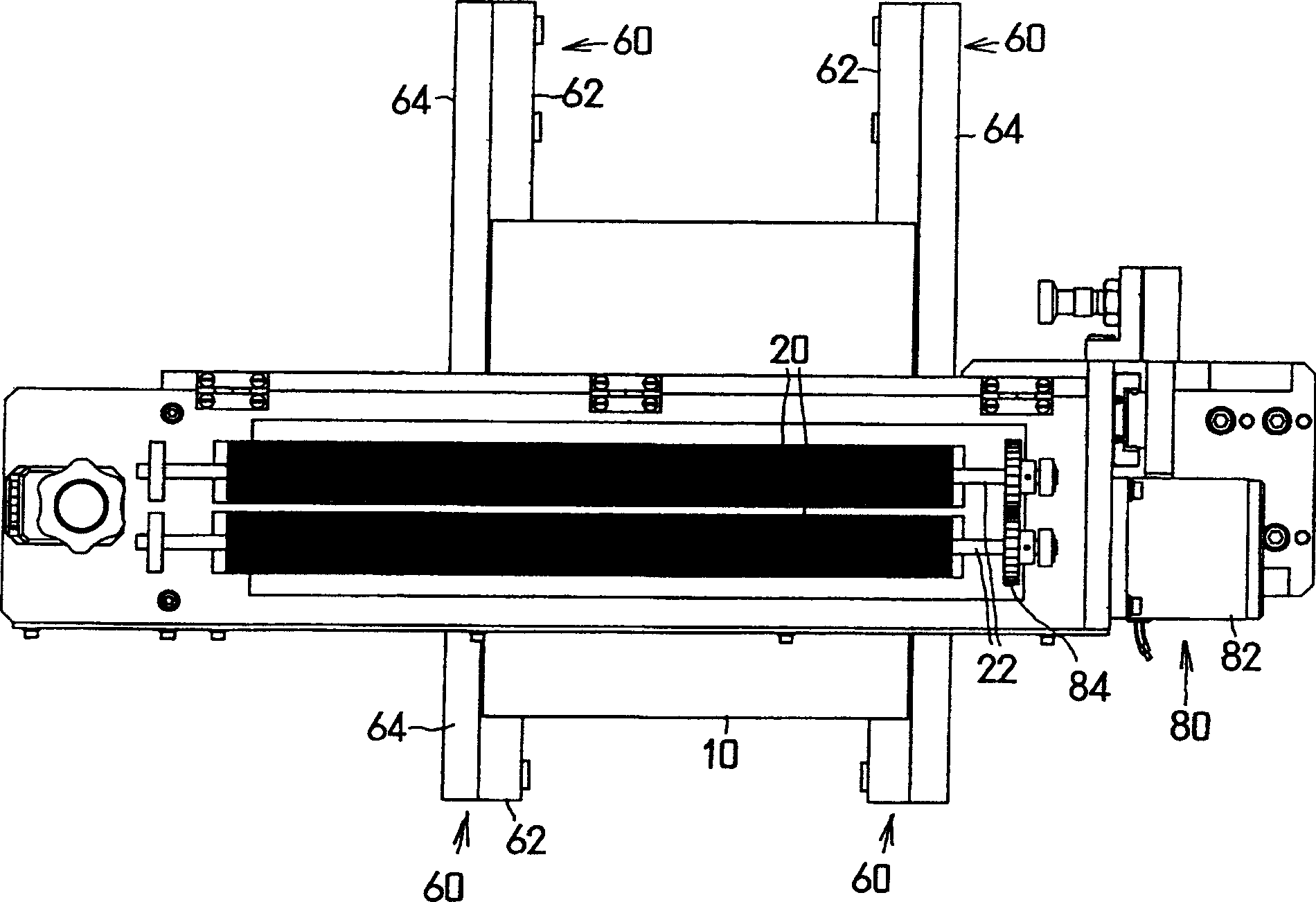

[0043] Figure 1 to Figure 3 A preferred embodiment of the substrate dust removal device of the present invention is shown, figure 1 It is a diagram illustrating its principle structure, figure 2 is its front view, image 3 It is a top view of the state with its dust removal device removed. Next, this substrate dust removal device will be described.

[0044] In this substrate dedusting device, such as figure 2 with image 3 As shown, a conveyor 60 for loading and transporting substrates 10 is included. The conveyor 60 is configured such that a pair of left and right endless endless belts 62 are synchronously circulated inside a pair of conveyor frames 64 in the same direction and at the same speed. At the same time, the substrate 10 mounted on the entire pair of left and right endless belts 62 is conveyed at the same speed as the endless belts 62 along the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com