Method for injection molding multi-layer plastic products and multi-layer plast ic products thereof

A technology for parts and plastics, applied in the field of multi-layer parts, which can solve the problems of complex devices and molds, inaccuracy, and complicated methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

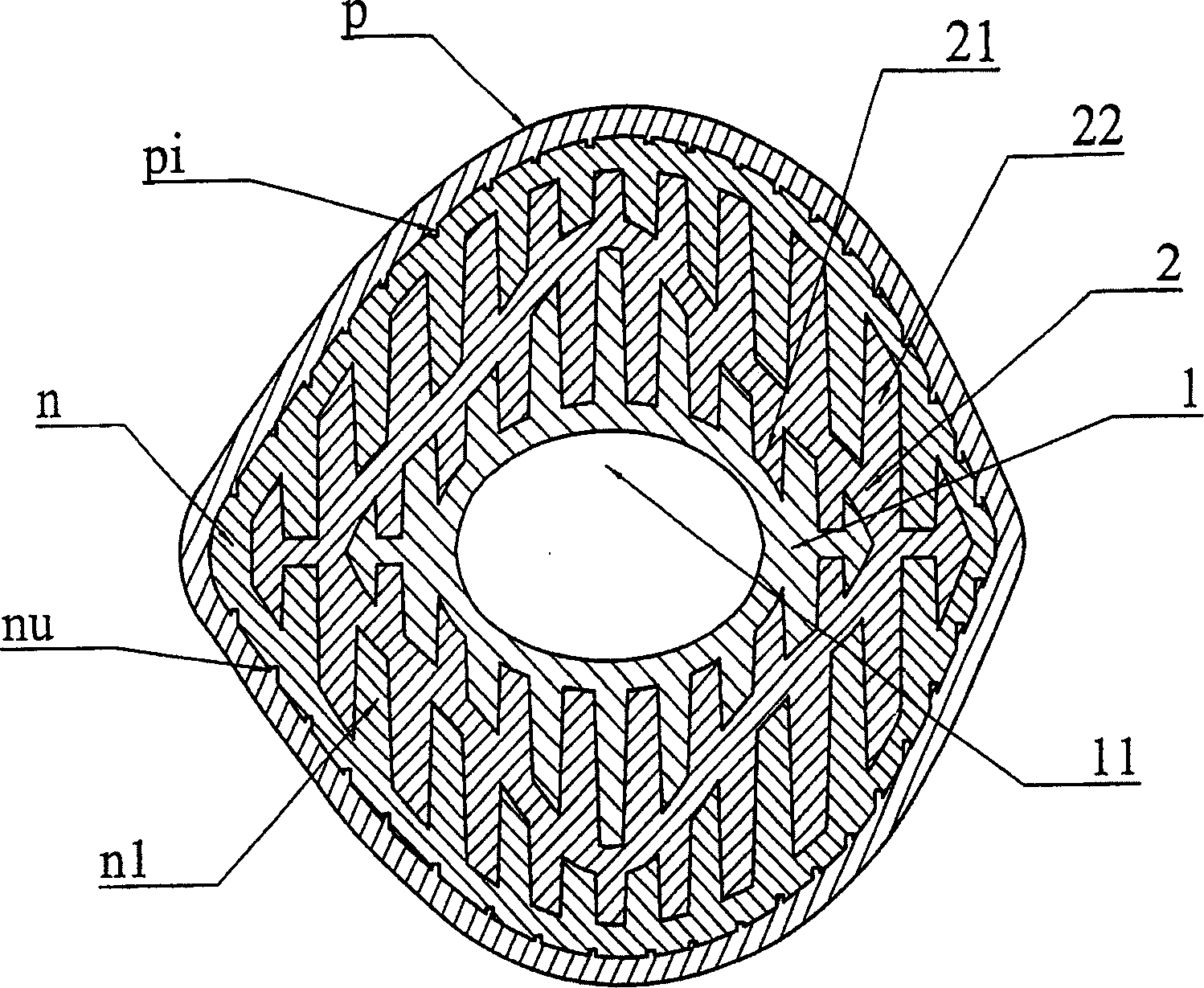

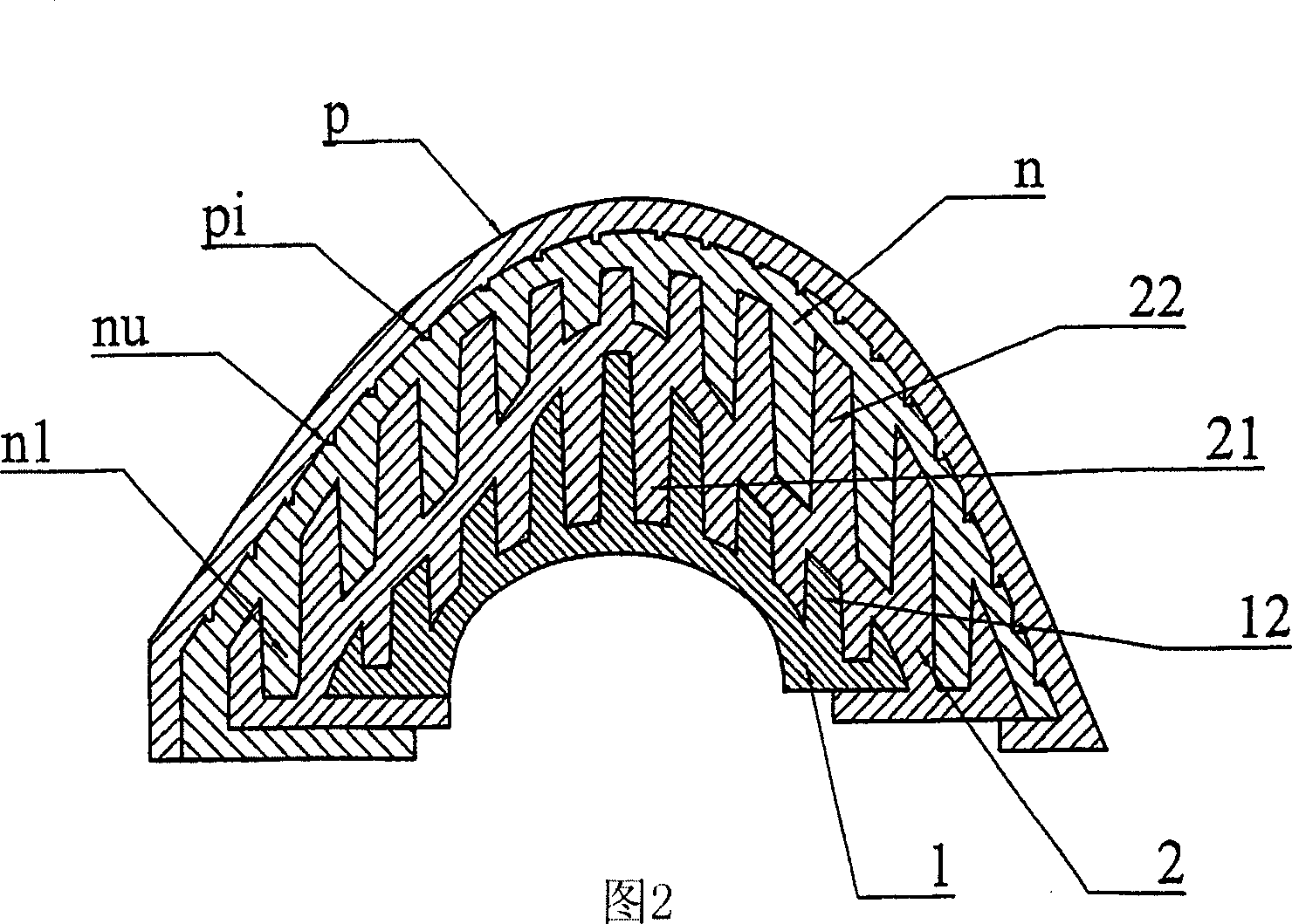

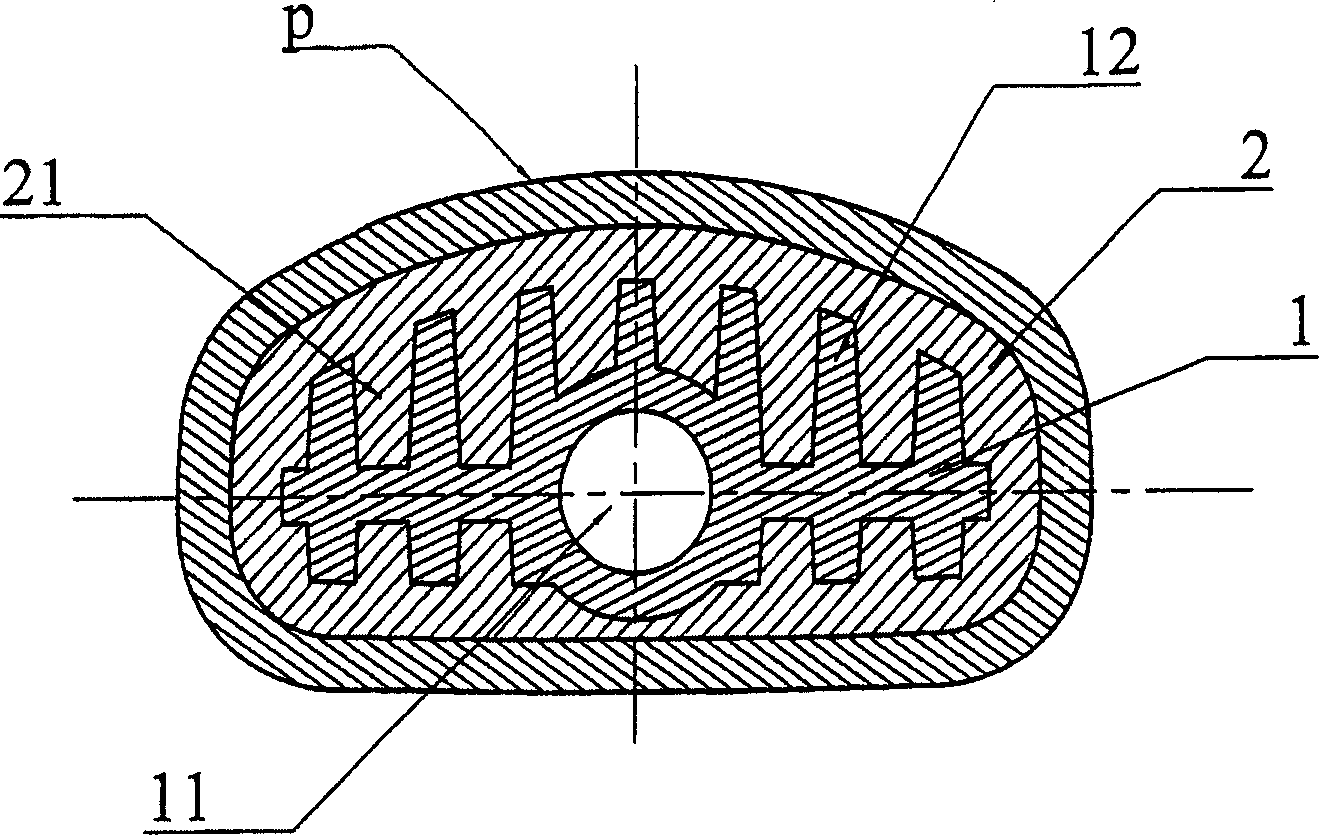

[0035] The injection molding process for multilayer plastic parts is: Injection molding layer 1, if said layer 1 is a component of a closed part (see figure 1 ), the segments 1' and 1" of layer 1 are injection molded. Ribs 12 are formed on the outer surface of layer 1. Segment 1 is made by a solid core in the mold, or by some other method The channel 11 in ' and 1 ", the channel 11 is mostly used to transport fluid, so it is required to be made of waterproof material, and the joint of segment 1' and 1" should be tightly sealed. Therefore, segment 1' and 1 " It can be joined in various ways, and the joint can be detachable or non-detachable, but it must be airtight. The detachable joint between the segments 1' and 1" is formed by inserting an 'O' shaped plug ring 14, or fastener / coupling at the inlet 13, also by gluing, welding at the inlet 13 , friction welding or ultrasonic welding, forming a non-detachable joint (see Figure 32 , 33 ).

[0036] Layer 1 produced in this w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com