Scroll compressor with hot oil temperature responsive relief of back pressure chamber

A scroll compressor and back pressure chamber technology, applied in the field of scroll compressors, can solve problems such as insufficient provision of unfavorable conditions for faster release and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

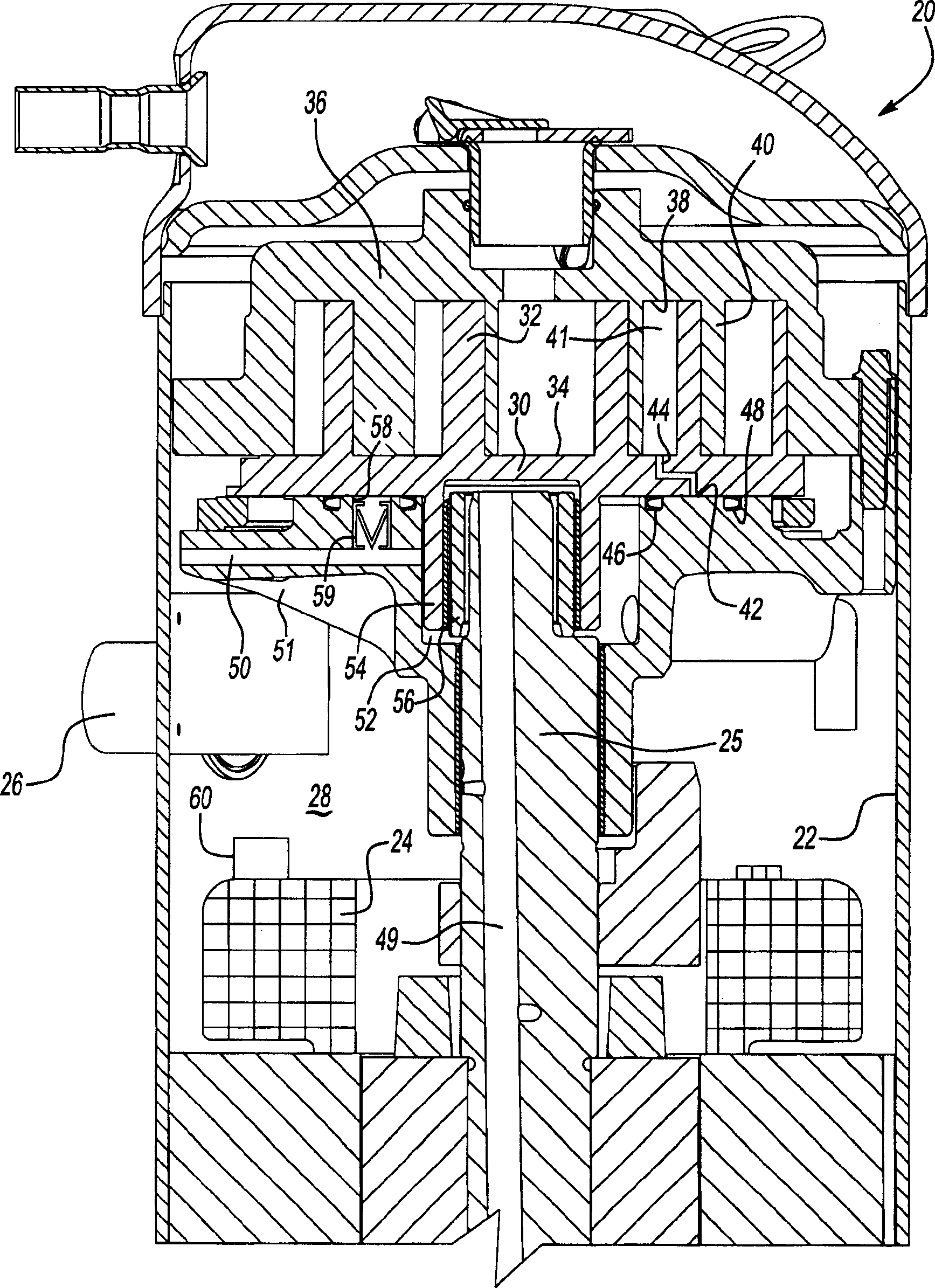

[0014] figure 1 A scroll compressor 20 is shown. Scroll compressor 20 is mounted within a sealed housing 22 . An electric motor 24 drives a shaft 25 to compress the refrigerant, as is known. Refrigerant enters the sealed housing 22 through the suction pipe 26 . A suction chamber 28 surrounds the motor through which refrigerant is drawn in to cool the motor.

[0015] A first scroll member 30 , known as an orbiting scroll, includes a helical outer shell 32 extending from a base 34 thereof. The scroll casings shown are of the so-called composite type, which have different thicknesses. Other types of scroll compressors are also within the scope of the present invention which include scroll casings formed on a circular involute, the casings of which have a relatively constant thickness. The orbiting scroll 30 faces a non-orbiting scroll 36 which has a base 38 in its own casing 40 extending from the base. As shown, the shells cooperate to define a compression chamber 41 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com