Connection structure for rolling drum and web rack of washing machine

A technology of drum washing machine and connection structure, which is applied to other washing machines, washing devices, textiles and paper making, etc., and can solve problems such as damage, screw breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following description, in the main structure of the front-loading washing machine of the present invention, the same parts as those of the conventional washing machine will be assigned the same reference numerals, and details will be omitted here.

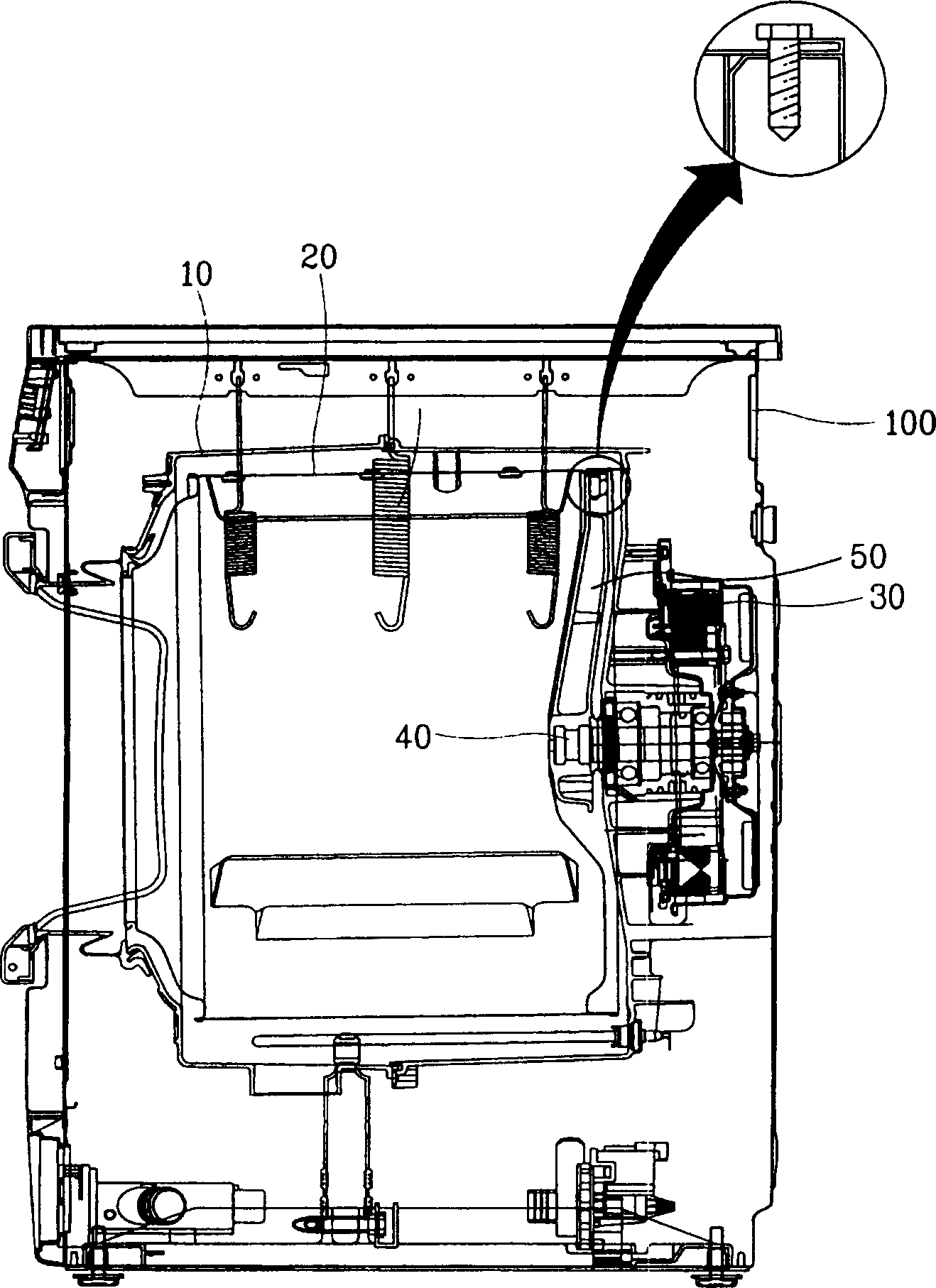

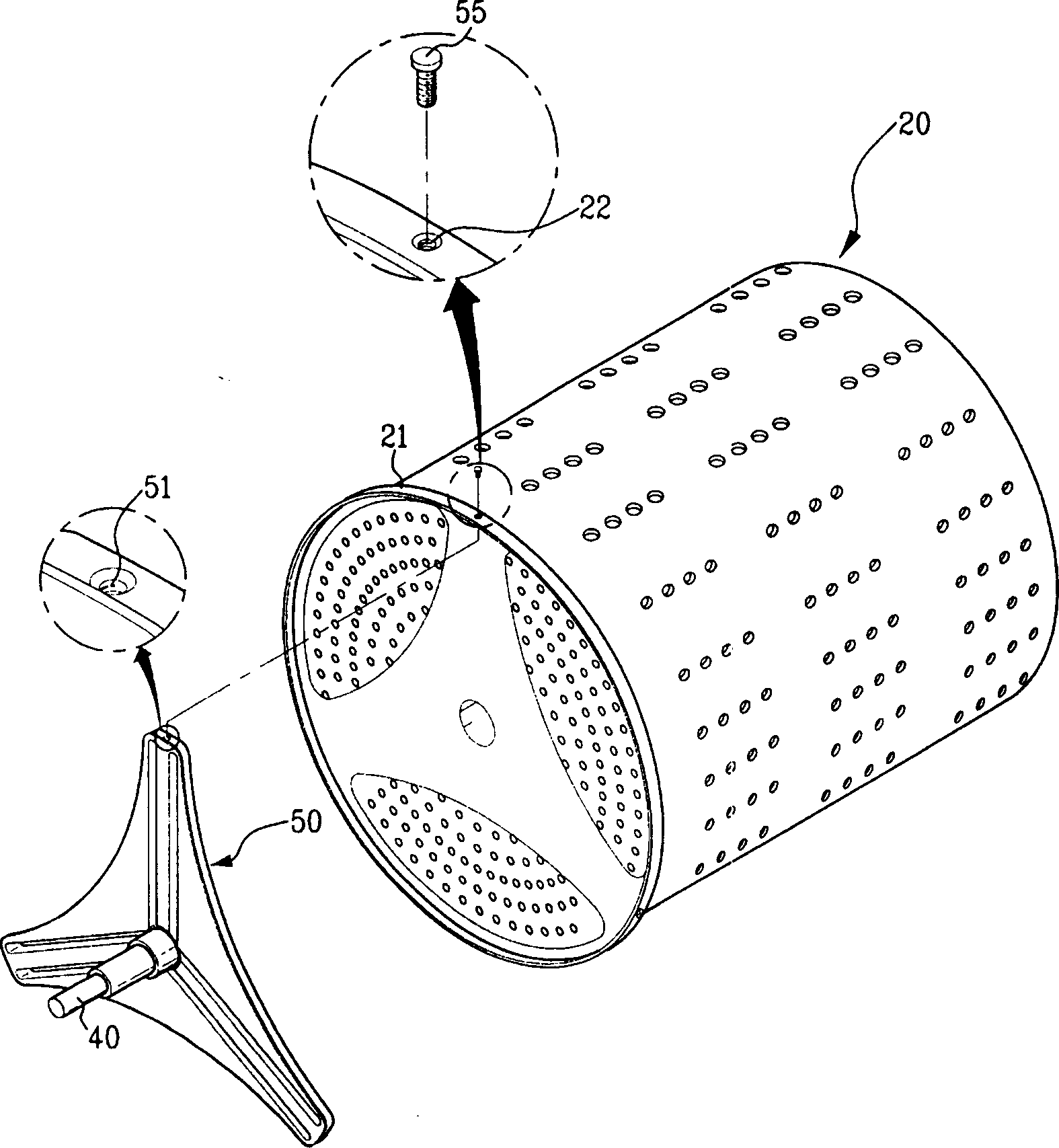

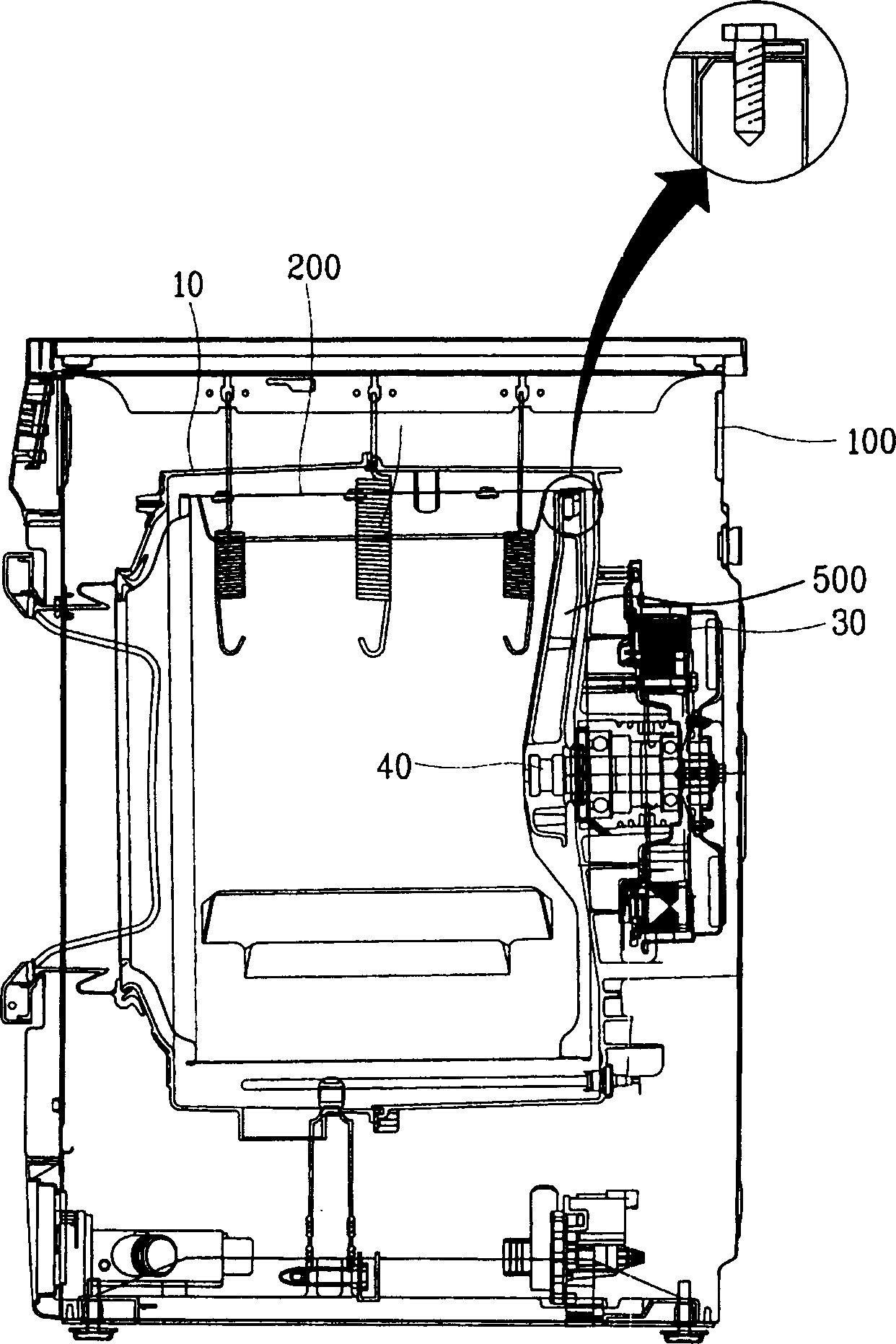

[0027] Such as Figures 3 to 5 As shown, cylinder rows of buckets (10) are arranged in parallel inside the housing (100). The cylinder row roller (200) is arranged on the inner side of the above-mentioned bucket (10) through the roller shaft (40). The drum (200) shares the same axis as the bucket (10) mentioned above. The drum (200) is rotated by the driving force of the driving motor (30).

[0028] The spider web-shaped support (500) is fixedly combined on the rear wall of the above-mentioned drum (200). The tail end of the above-mentioned roller shaft (40) is fixed at the center of the spider web-shaped support (500).

[0029] Such as Figure 4 and Figure 5 As shown, the spider web support (500) is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com