Frame structure

A frame and component technology, applied in the field of frame structures, can solve the problems of no known patent documents and the inability to use scaffolding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

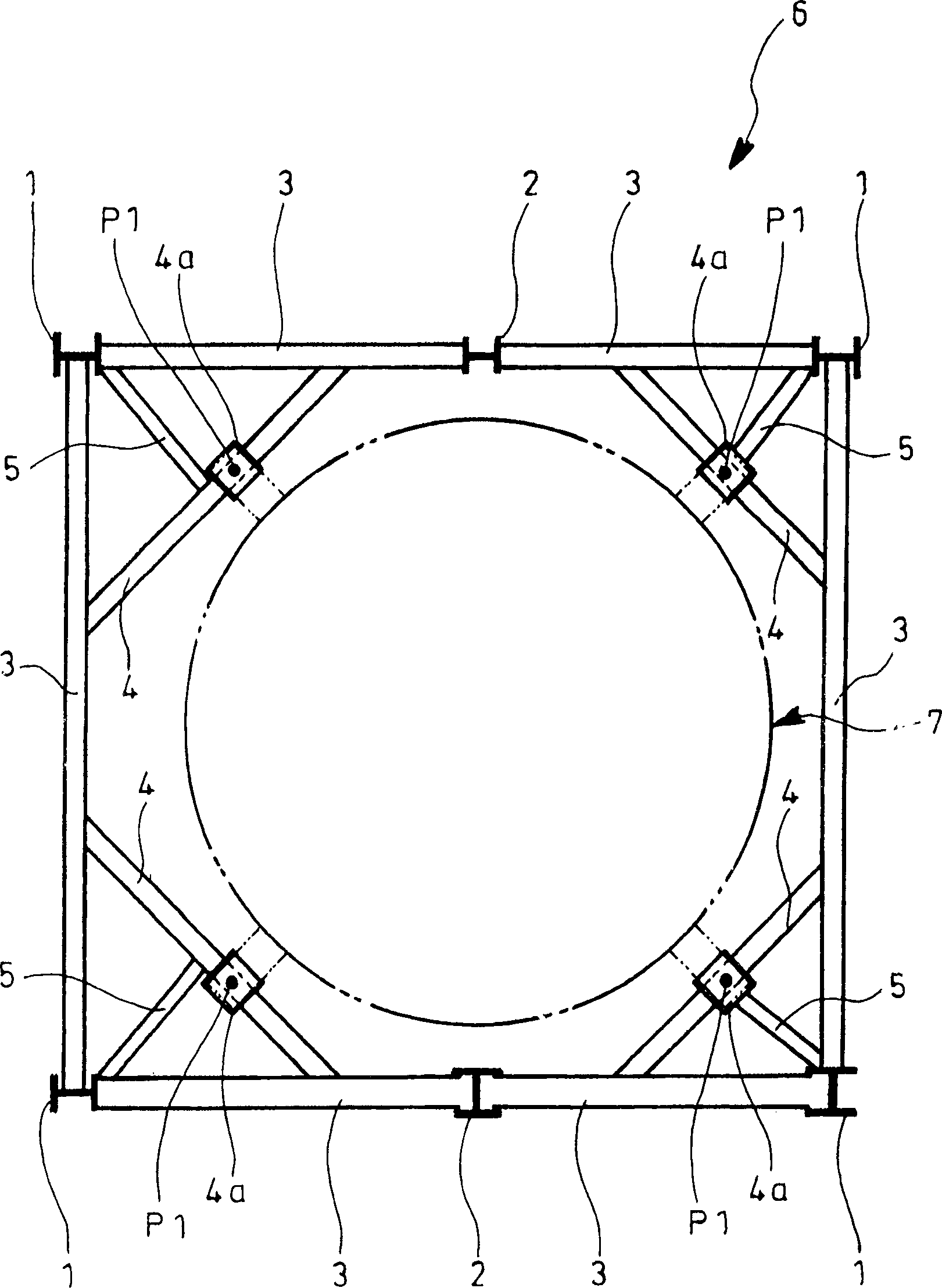

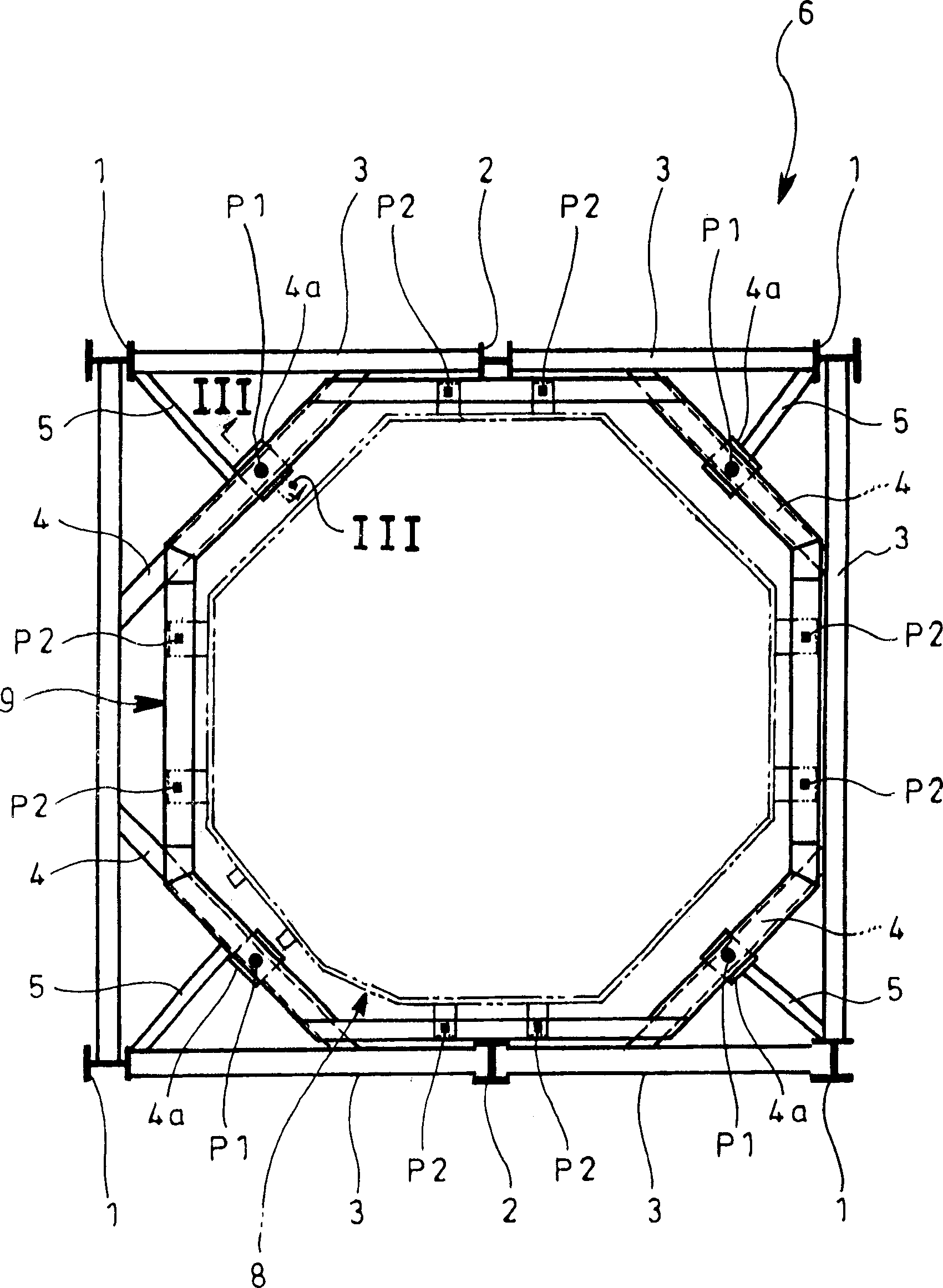

[0018] Hereinafter, embodiments of the present invention will be described together with illustrated examples.

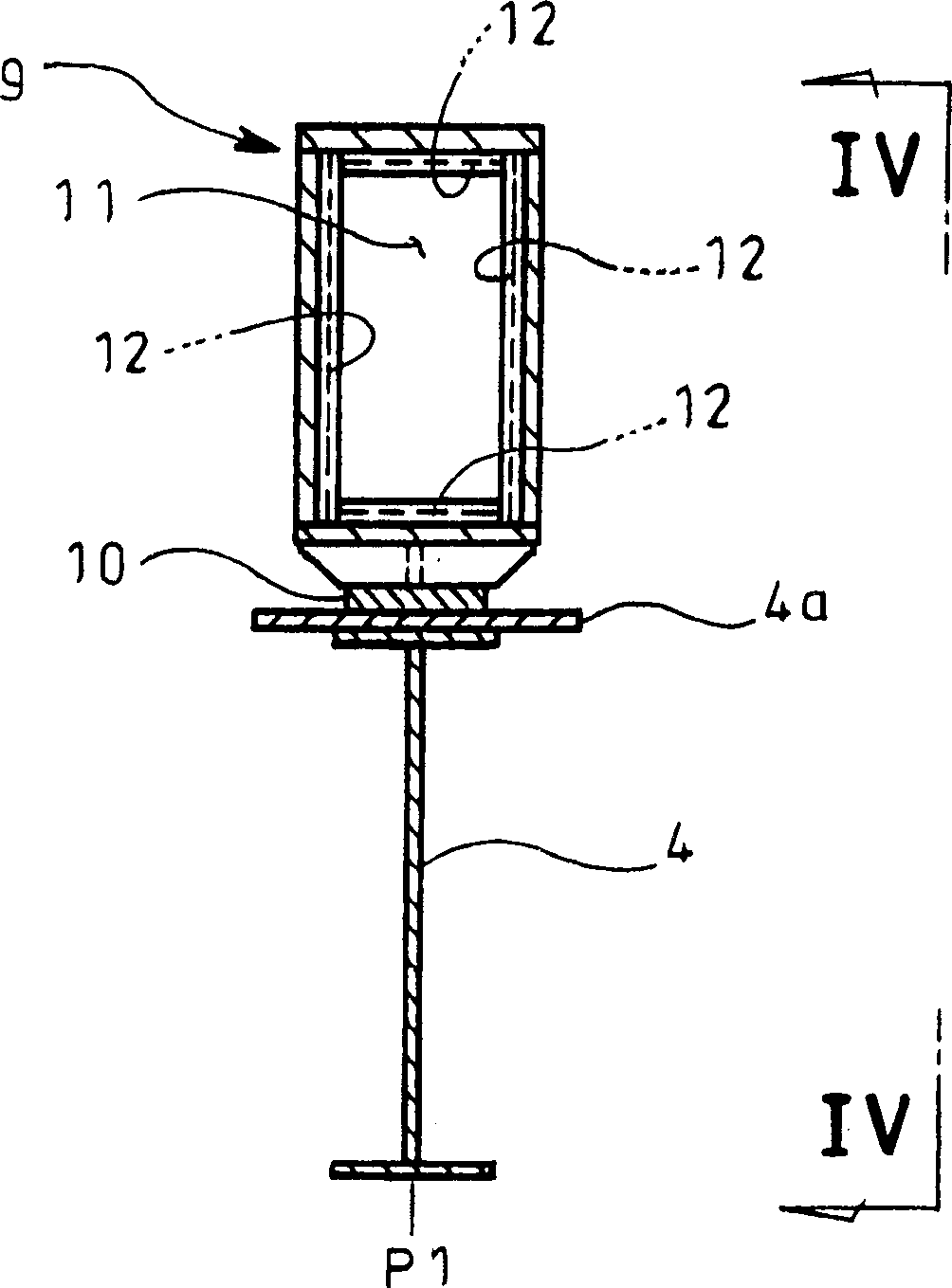

[0019] Figure 2 ~ Figure 4 is an example of the manner of implementing the present invention, in the figure, marked with figure 1 The part of the same symbol represents the same component, and the basic structure of the frame structure of the present invention is the same as figure 1 The previous frame structure shown is the same, but as Figure 2 ~ Figure 4 As shown, the feature of the example shown in this figure is that it is provided with: ring beam 9, which is relative to the load support point P1 of the fixed air preheater 7 as a part of the existing machine on the frame 6, and transfers it as a new design. Mechanical components The load of the rotary air preheater 8.

[0020] In the case of the example shown in this figure, the load of the rotary air preheater 8, which is a newly installed mechanical component, acts on the load support point P2 of the rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com