Reactor arrangement for carrying out catalytic gas reactions

A reaction device and phase reaction technology, applied in the chemical method, installation, organic chemistry and other directions of reacting gaseous medium with gaseous medium, can solve the problems of uneven load of cooling pipe, inconvenient maintenance, high cleaning cost, etc. The effect of reducing the risk of subsequent reactions, reducing cleaning costs, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

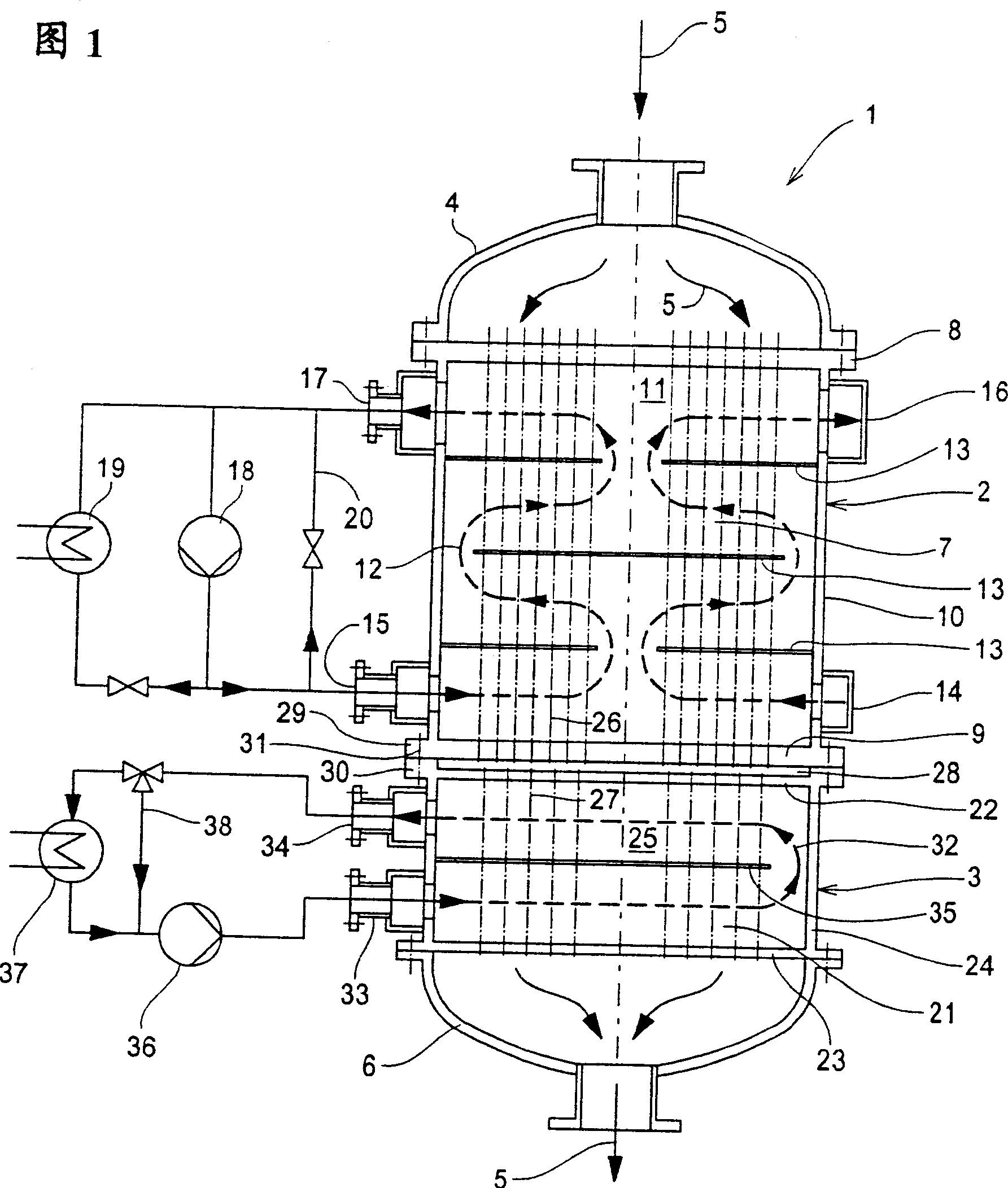

[0036] The shown exemplary embodiment of the reaction apparatus 1 according to the invention has a tubular reactor 2 and an aftercooler 3 connected directly downstream therefrom. The reaction gas 5 is introduced into the jacketed reactor 2 through a gas inlet hood 4 . After flowing through the jacketed reactor 2 and the aftercooler 3 , the reaction gas 5 is removed from the reaction device 1 by means of a gas outlet hood 6 .

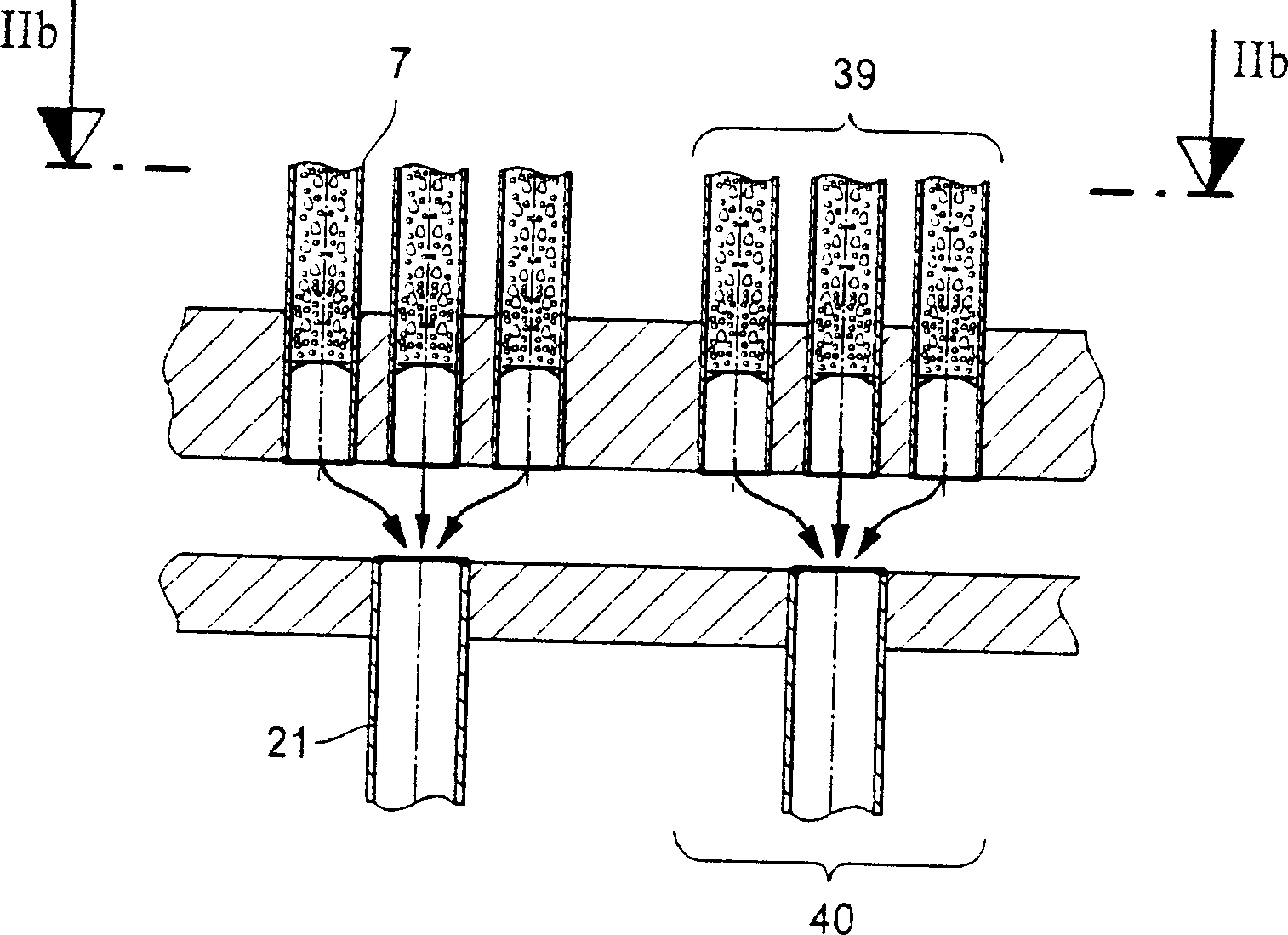

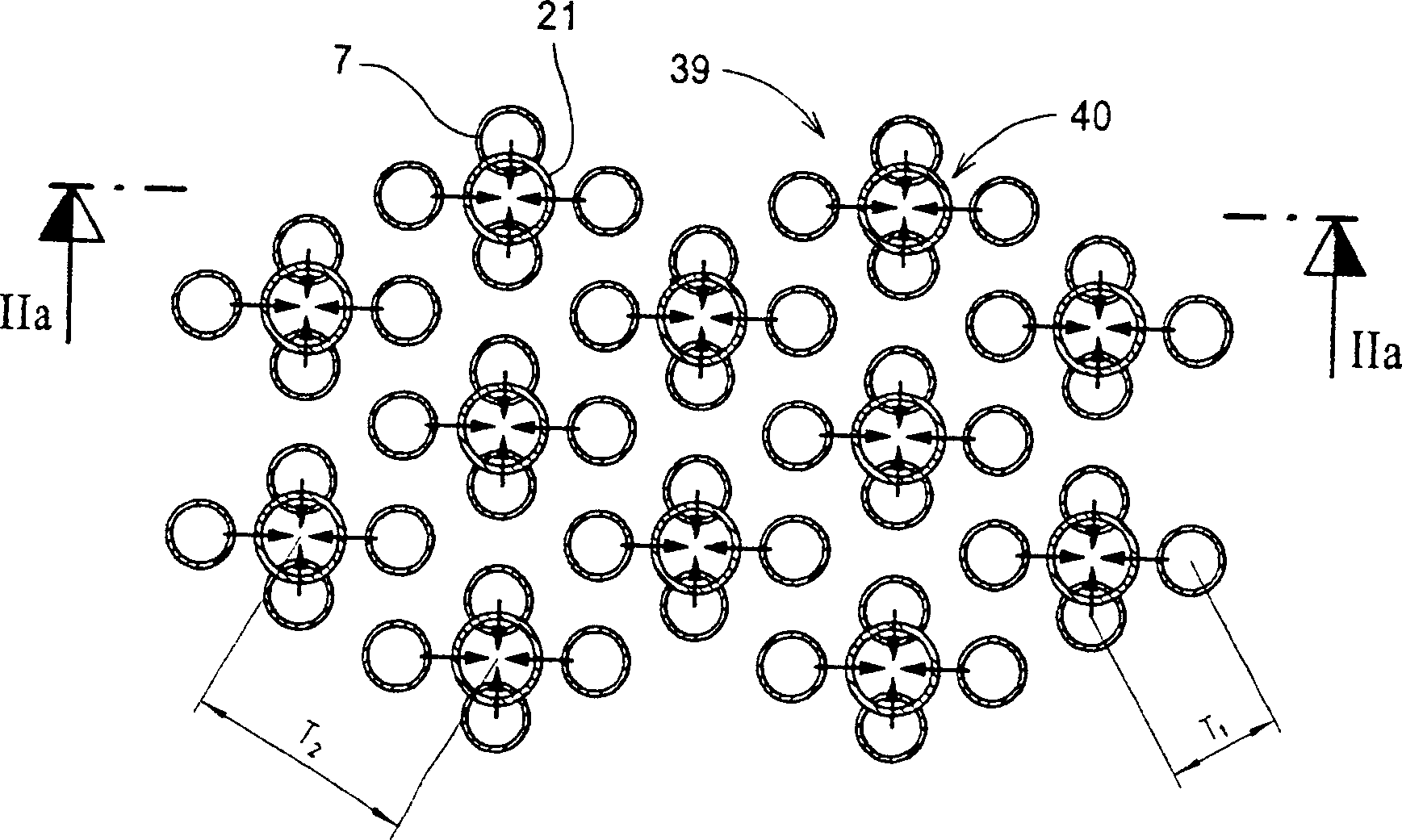

[0037] The jacketed reactor 2 (FIG. 1) comprises a plurality or bundle of catalyst-filled reaction tubes 7 extending vertically between an upper tube base 8 and a lower tube base 9 and surrounded by a cylindrical sleeve 10, in which The outer sides of the two ends of the reaction tube 7 are gas-tightly welded to the corresponding tube bottoms 8 and 9 . A tubeless zone 11 is formed at the center of the reaction tube bundle 7 .

[0038] The reaction tubes are sprayed / rinsed around by a heat transfer medium 12 which passes through the reaction tube bundle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com