Substrate holding device and polishing device

A substrate holding and substrate technology, which is applied in the directions of grinding devices, electrical components, circuits, etc., can solve the problem that the grinding rate of semiconductor wafers cannot be fully and arbitrarily controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

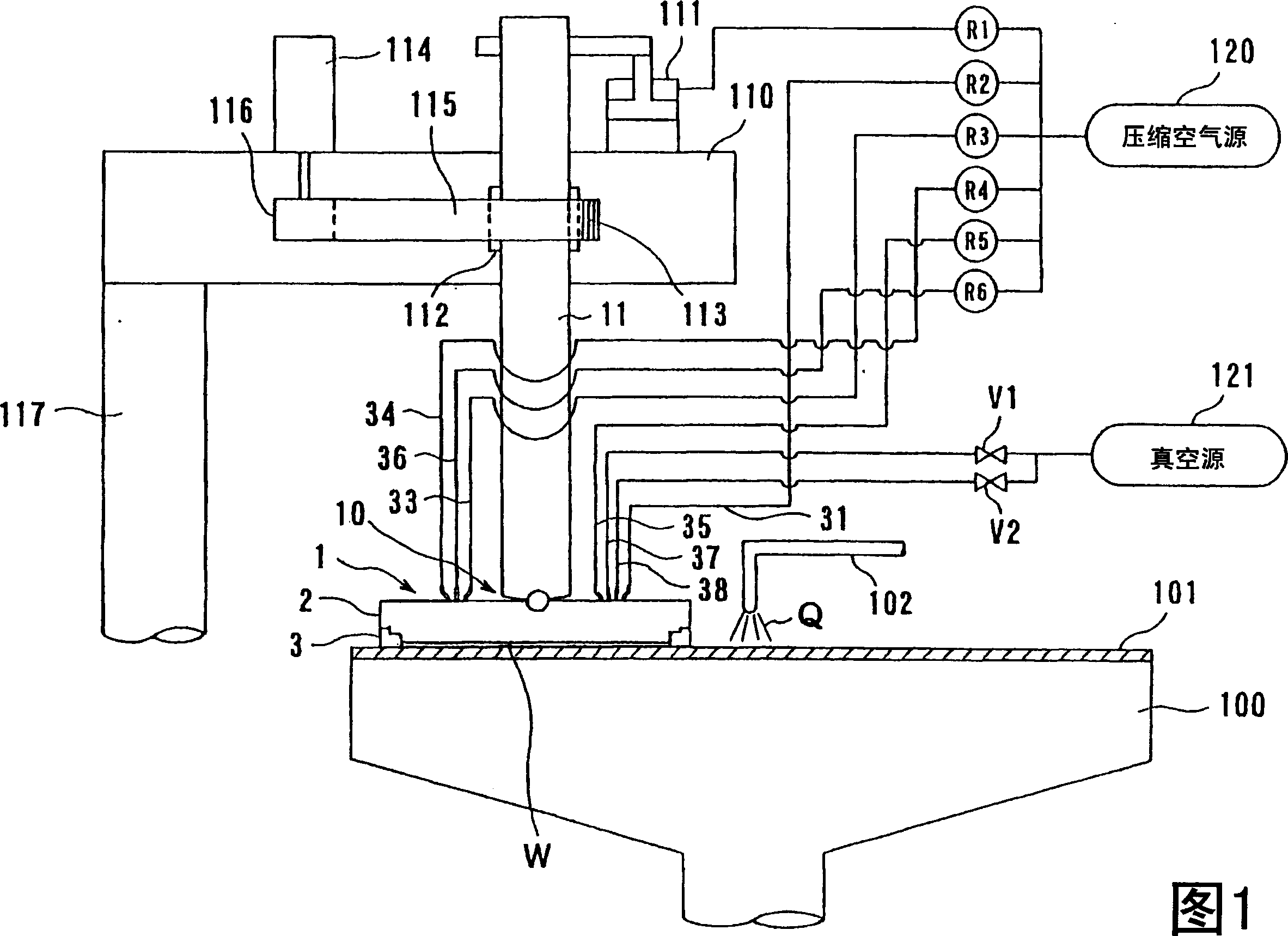

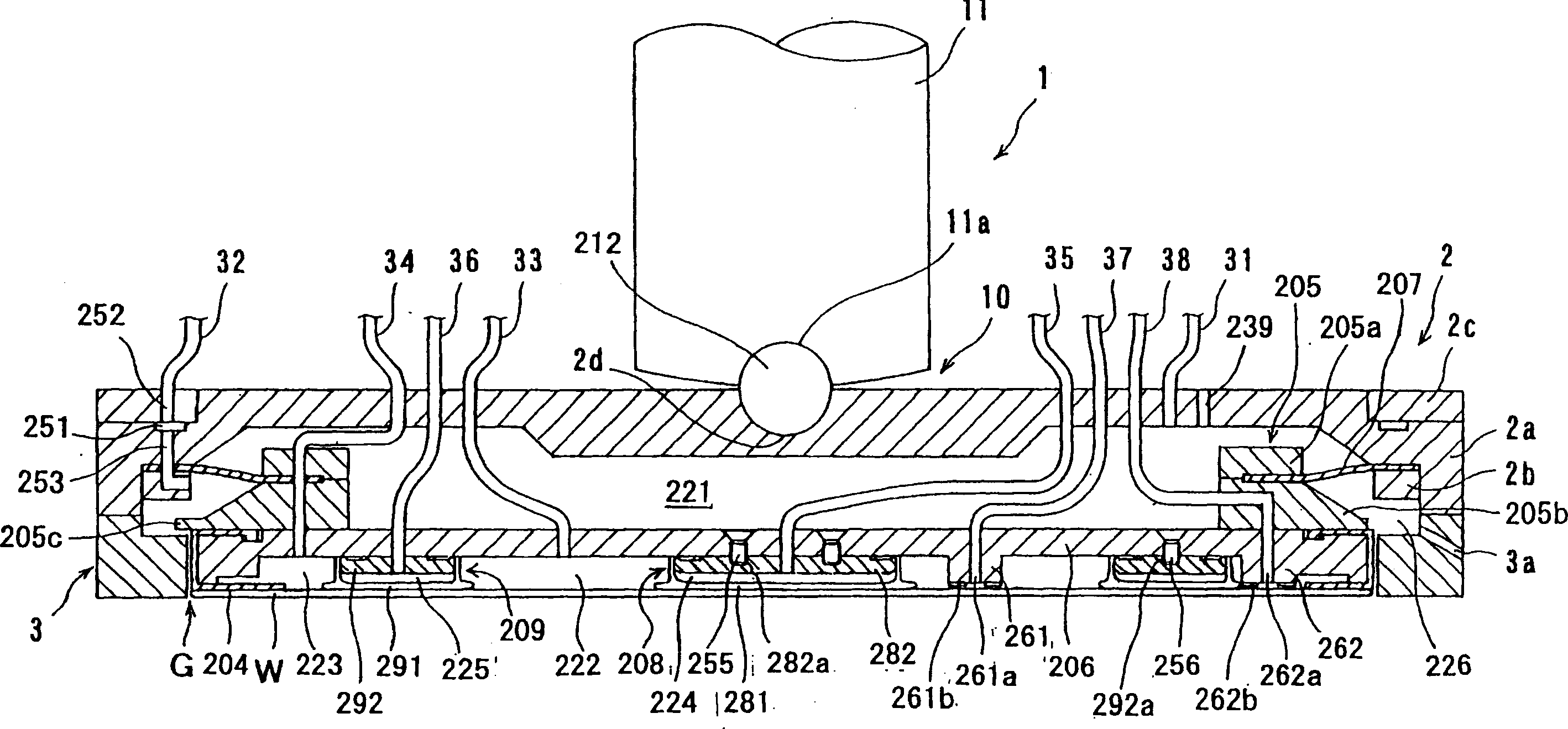

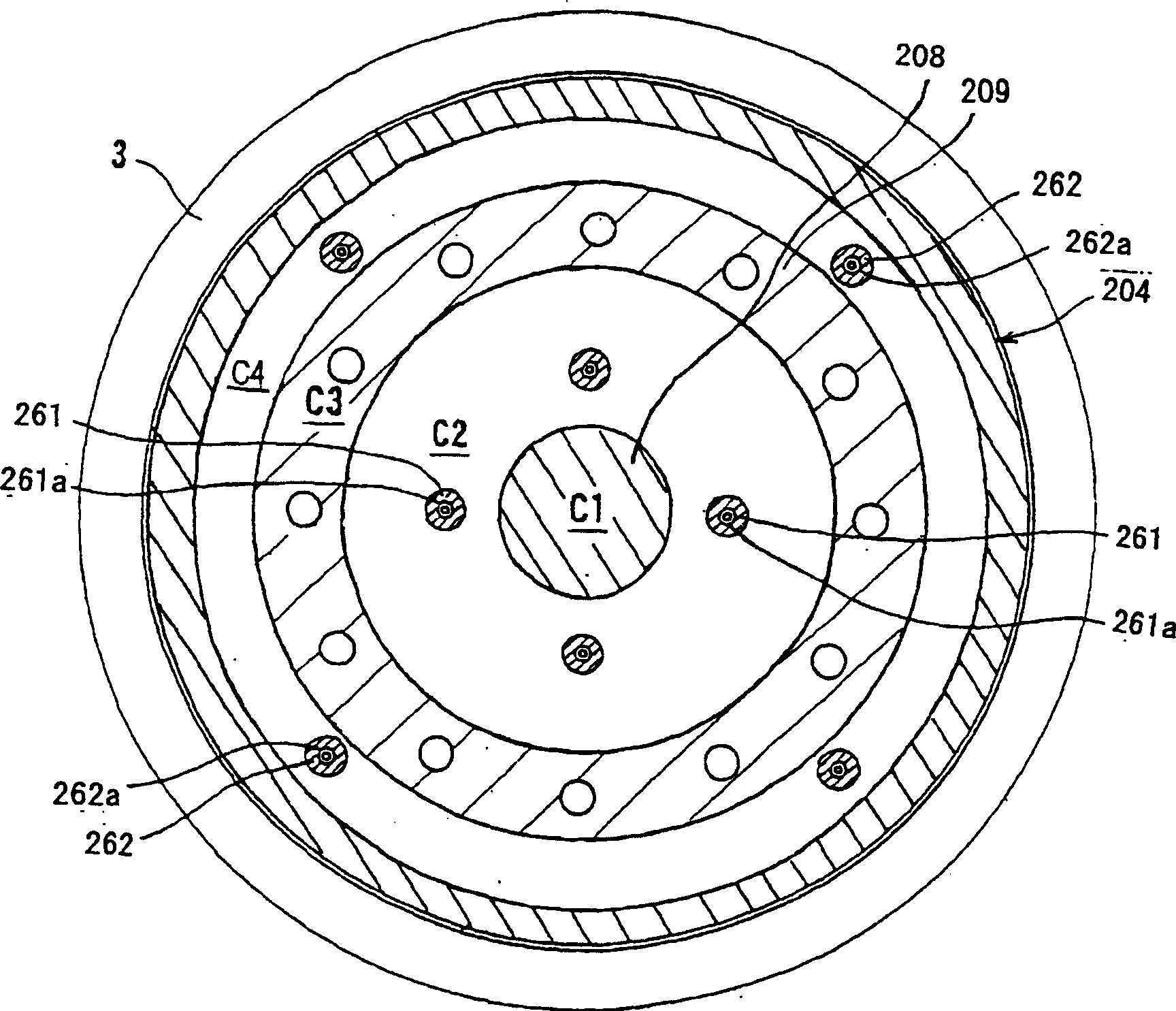

[0070] FIG. 1 is a cross-sectional view showing the overall structure of a polishing apparatus including a substrate holding device according to the present invention. Here, the substrate holding device is a device that holds a substrate such as a semiconductor wafer as an object to be polished and presses it against a polishing surface on a polishing table. As shown in FIG. 1 , below a top ring 1 constituting a substrate holding device according to the present invention, a polishing table 100 on which a polishing pad 101 is pasted is provided. In addition, a polishing liquid supply nozzle 102 is provided above the polishing table 100 , and the polishing liquid Q is supplied to the polishing pad 101 on the polishing table 100 through the polishing liquid supply nozzle 102 .

[0071] In addition, as a commercially available polishing pad, there are various pads, for example, SUBA800, IC-1000, IC-1000 / SUBA400 (two-layer cloth) manufactured by Rodell Corporation, Fujimi Co., Ltd....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com