Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., which can solve the problems of partial wear and slow wear, and achieve the effect of partial wear improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

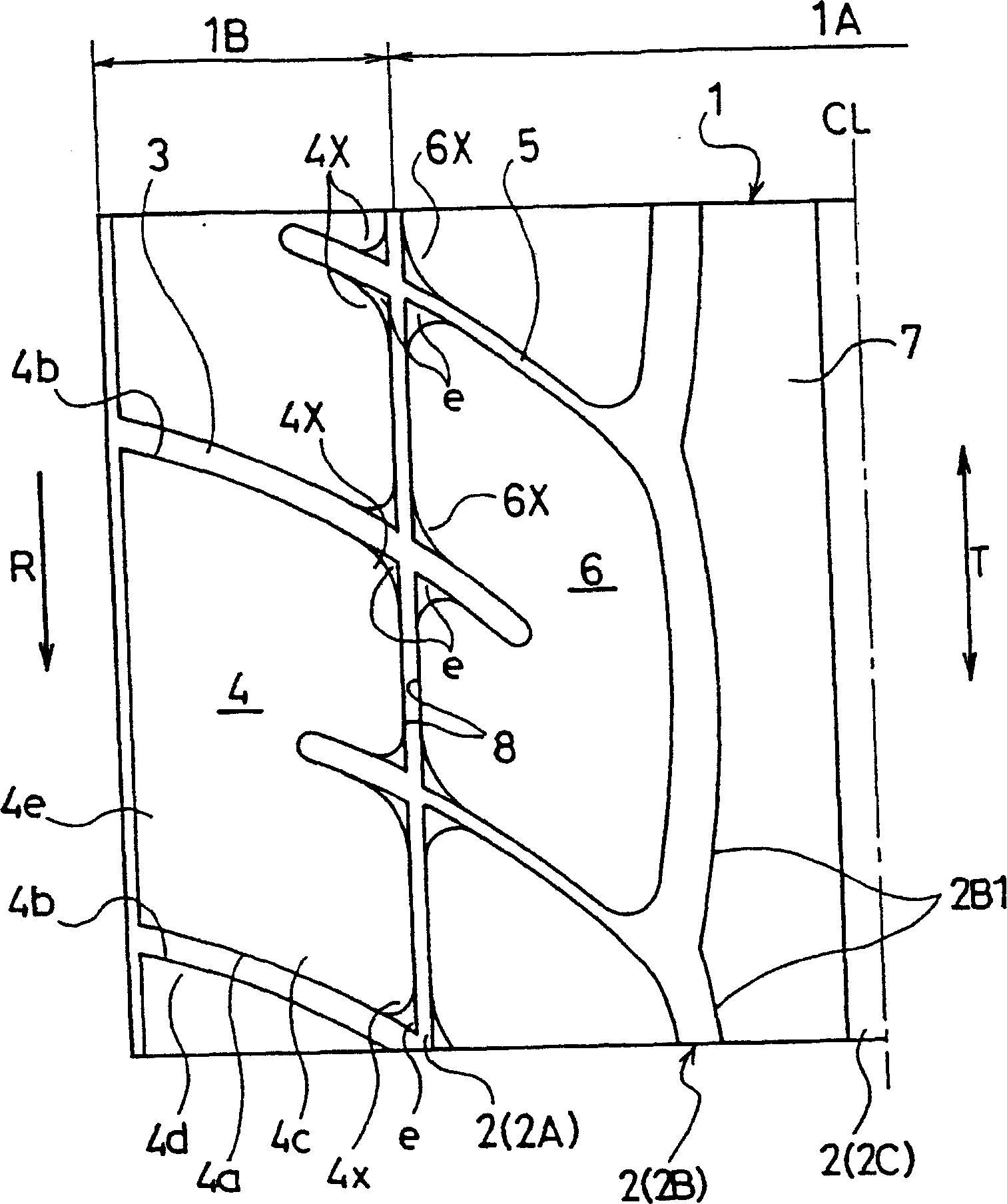

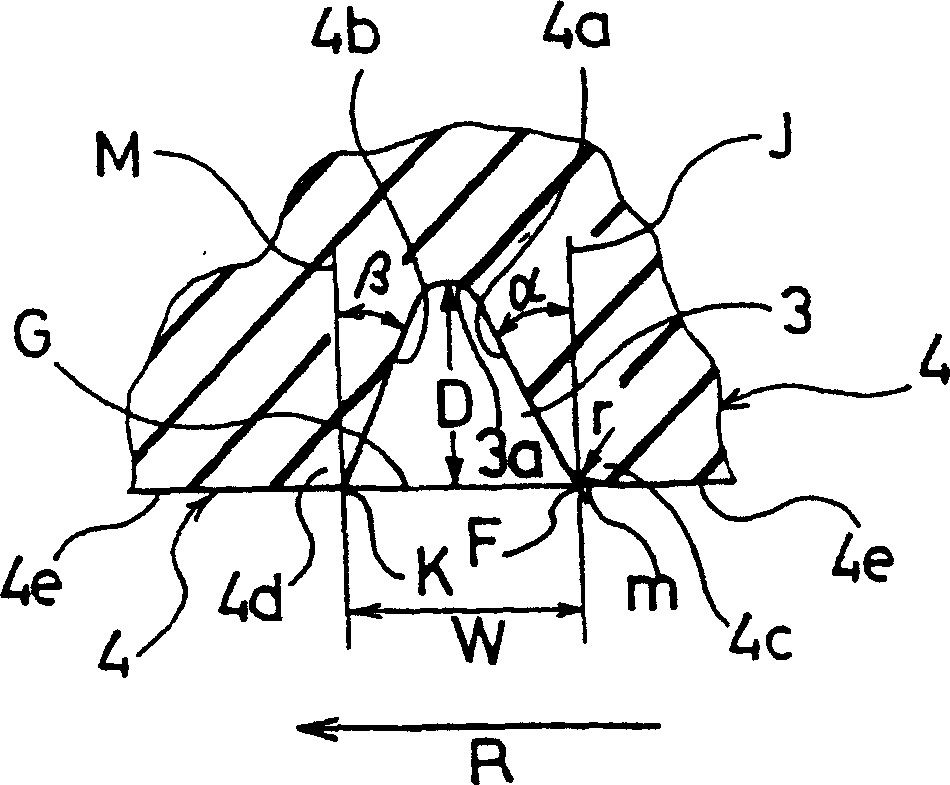

[0035] Set the tire size to be the same as 235 / 45ZR17, and set the tread pattern according to figure 1 Assuming the same, the relationship between the inclination angle α of the side groove wall surface in the tire rotation direction and the inclination angle β of the tire anti-rotation direction side groove wall surface of the block in the shoulder region is respectively made as β > α, and the tire rotation direction side edge The tires of the present invention were chamfered in an arc shape, the tires of the present invention were not chamfered at the side edges in the direction of rotation of the tire, and the conventional tires of the comparative tires were made with an inclination angle α greater than the inclination angle β.

[0036] In the tire of the present invention, the inclination angle α is 0.30×tan -1 (2D / W), the inclination angle β is 0.85×tan -1 (2D / W), the radius of curvature r of the chamfered surface is 3mm. The inclination angles α and β of conventional t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com