Method and device for squeezing viscous material

A technology of extrusion device and extrusion direction, which is applied in the directions of packaging, transportation and packaging, and unsealing of objects, and can solve the problems of dirtying the extrusion device, falling of liquid 21, wasting liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

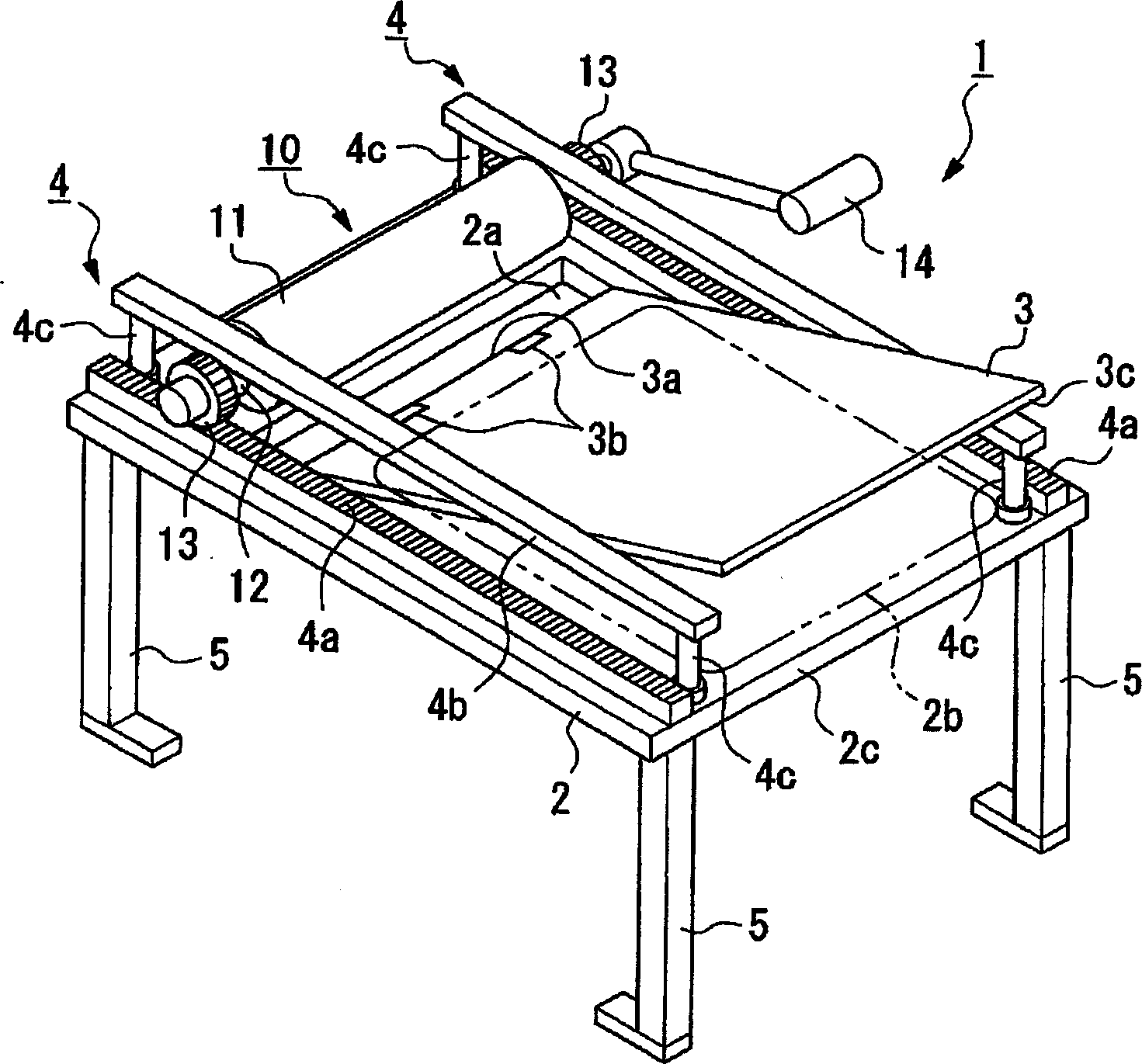

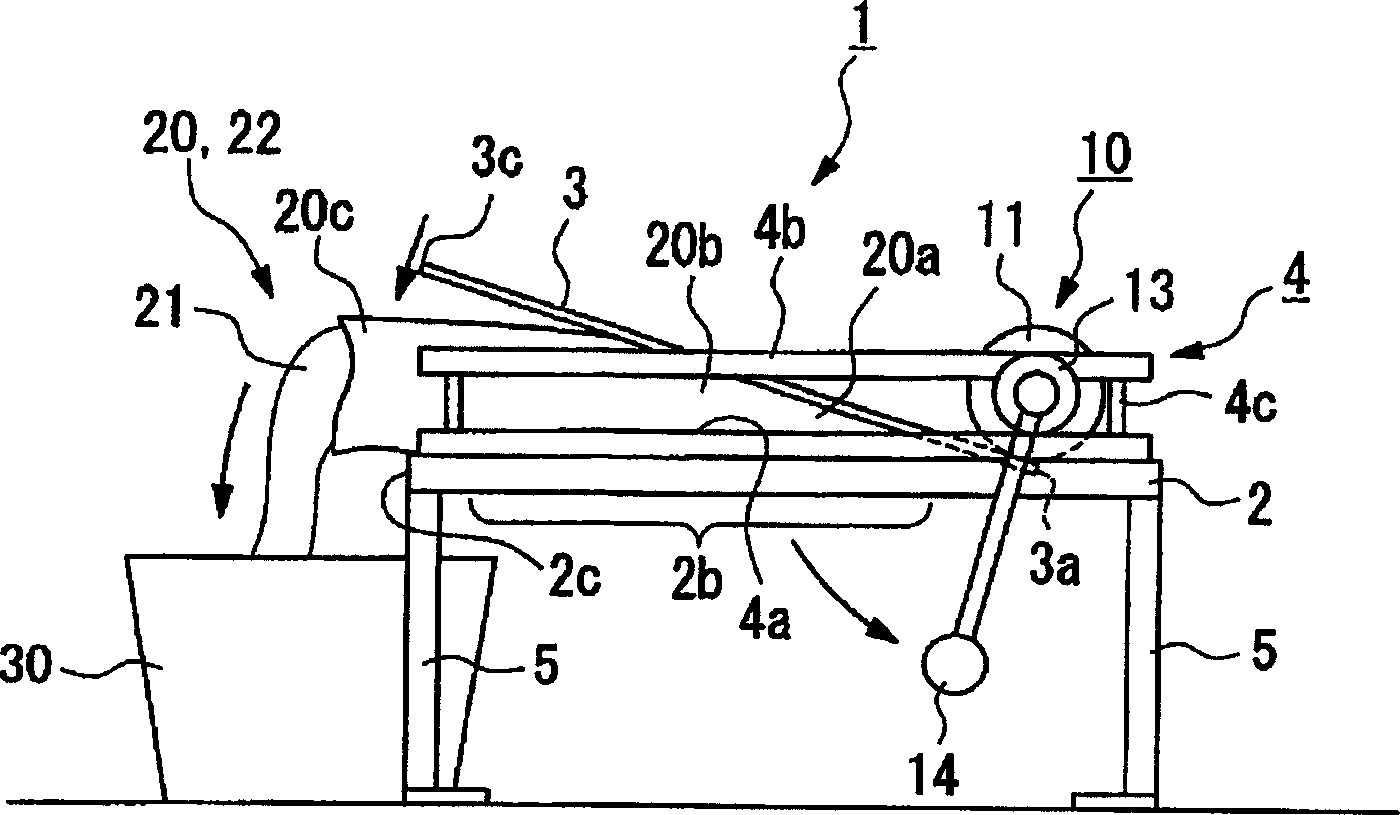

[0017] The extrusion device 1 has: a rectangular support plate 2 on which a package can be placed and supported; one end 3a is rotatably connected to an end edge of a long hole 2a formed on the support plate 2 through a hinge 3b. Push plate 3. The supporting plate 2 and the pressing plate 3 function as plate-shaped members for pinching the package.

[0018] The support plate 2 is spanned by legs 5 arranged at its four corners, and constitutes a stand for placing packages. The package support region 2b on the surface of the support plate 2 that faces the pressing plate 3 has a sufficient area for placing packages.

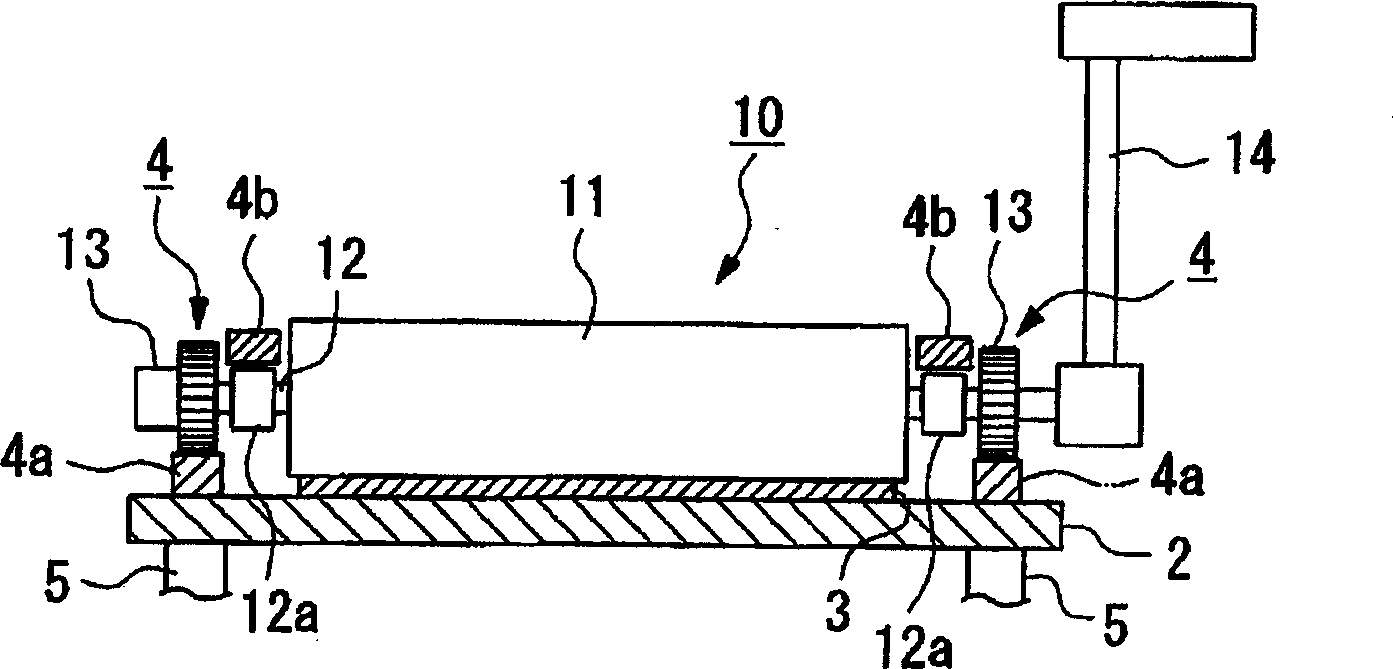

[0019] A roller 10 is arranged in a horizontal state on the supporting plate 2, and the roller 10 is able to run, and pushes the pressing plate 3 from one end 3a to the other end 3c on the opposite side.

[0020] The drum 10 has: a drum body 11 made of a cylinder made of stainless steel or hard plastic; and a shaft 12 formed to extend in the longitudinal direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com