In-mold forming apparatus, in-mold forming method, in-mold formed article manufacturing method, and dust collector

An internal forming and cavity technology, applied in chemical instruments and methods, cleaning methods and utensils, transportation and packaging, etc., can solve the problems of increased manufacturing costs, low yield, and continuous manufacturing of defective objects, and achieve efficient accumulation. , the effect of preventing defective objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

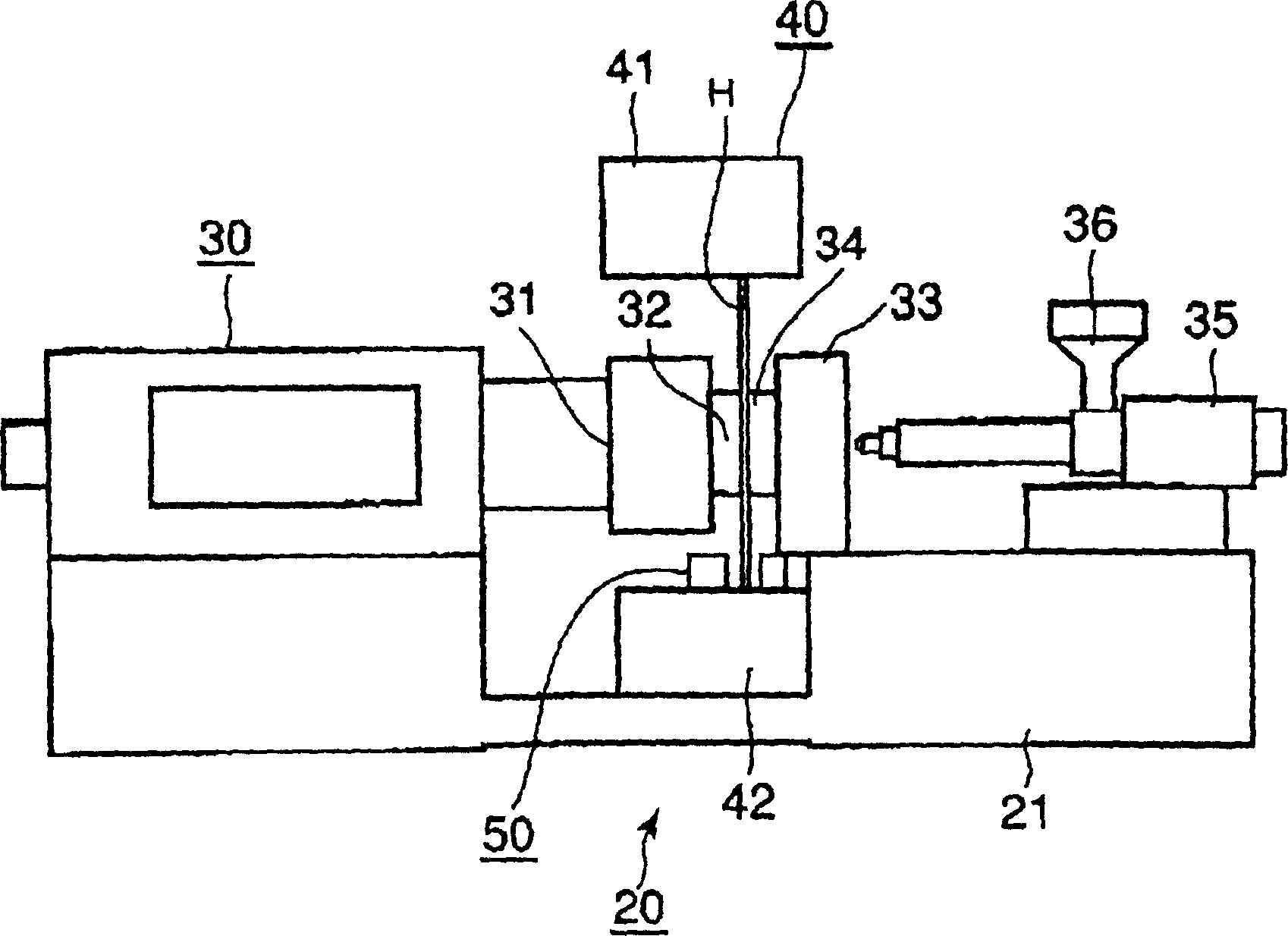

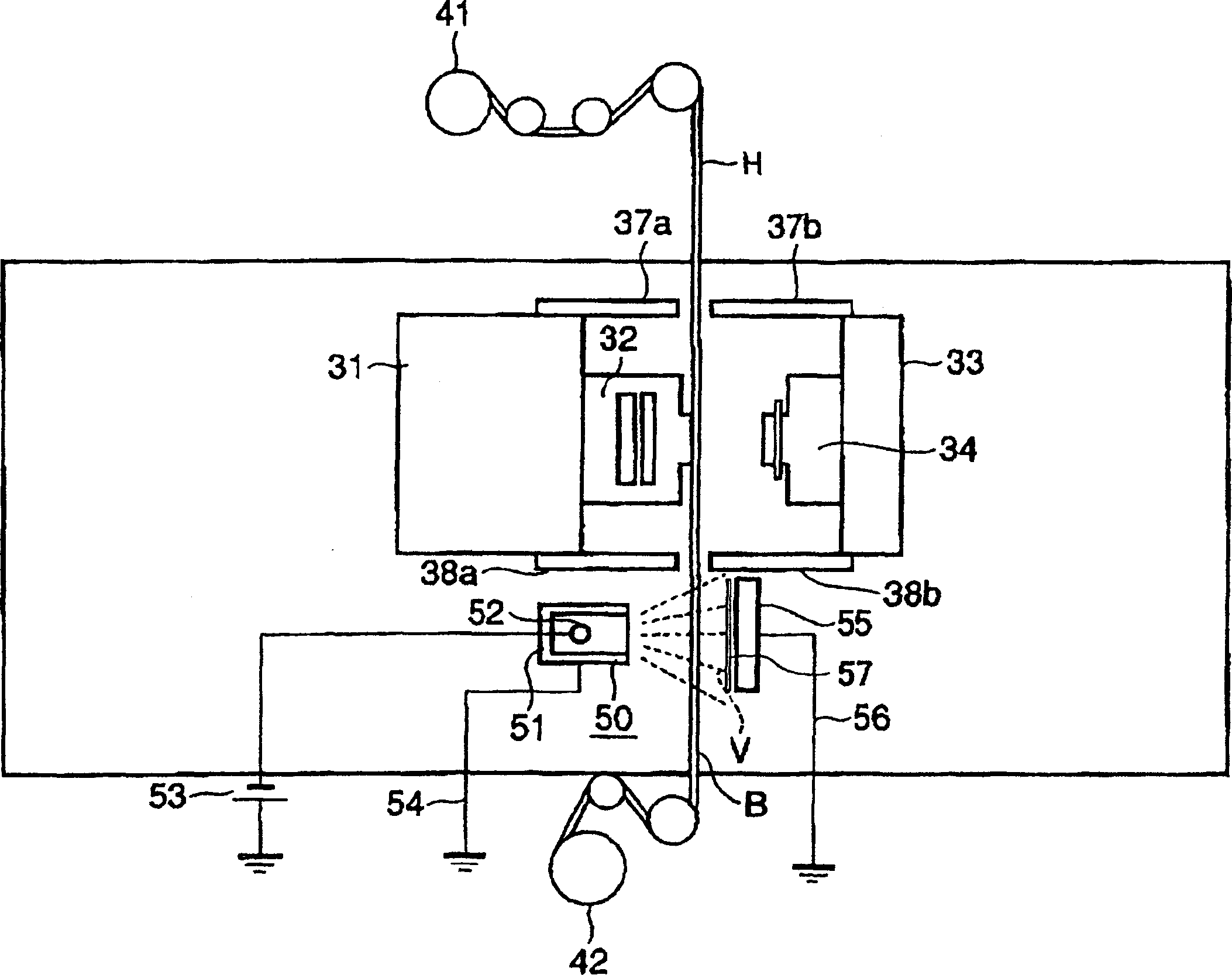

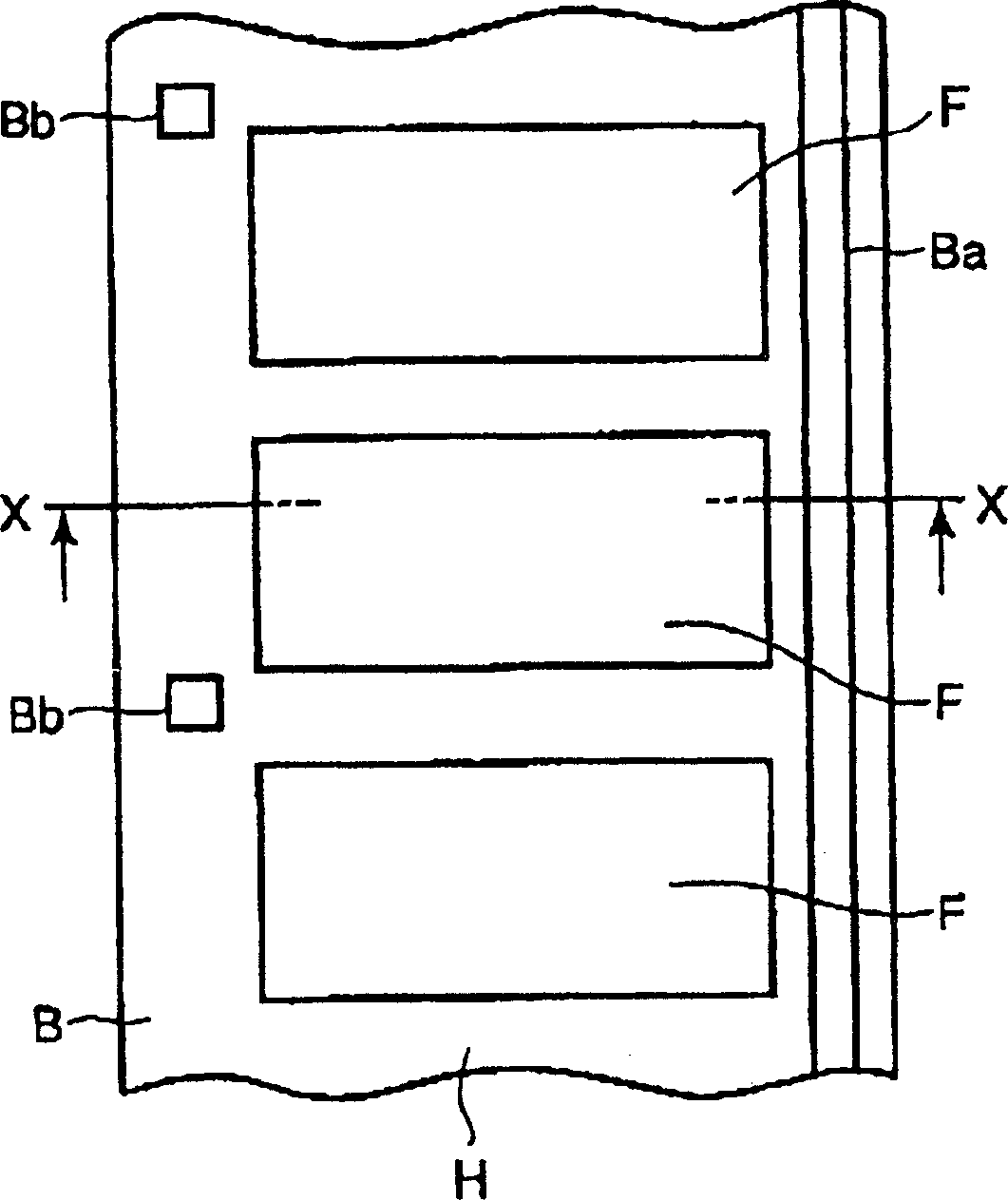

[0039] figure 1 is a front view showing the in-mold forming device 20 according to the first embodiment of the present invention, figure 2 is a schematic diagram showing the main parts of the in-mold forming device 20; image 3 is a front view showing the in-mold foil H used in the in-mold forming device 20; Figure 4 and Figure 5 is along image 3 A cross-sectional view of an example of the inner foil H cut along the middle section line X-X and viewed from the direction of the arrow; Figure 6 yes means figure 1 An illustration of the principle of operation of the in-mold forming device 20 shown; Figure 7 to Figure 9 are cross-sectional views each showing the injection molding step of the in-mold forming device 20; in addition, in these drawings, the numeral H denotes an in-mold foil, B denotes a base film, F denotes a transfer foil, and P denotes foil dust.

[0040] Such as figure 1 As shown, the in-mold forming device 20 is provided with: a frame 21 loaded on t...

no. 2 example

[0055] Figure 10 It is a perspective view schematically showing an in-mold forming device 60 according to a second embodiment of the present invention. exist Figure 10 use the same notation in the figure 2 The same functional parts shown in , and its detailed description is omitted.

[0056] In the aforementioned in-mold forming apparatus 20 of the first embodiment, the charger 50 is installed only on the foil winder side viewed from the cavity side mold 32 and the core side mold 34 . However, in the in-mold forming apparatus 60 of the present embodiment, the charger 50 is additionally installed on the foil feeder 41 side as well as on the cavity side mold 32 and the core side mold 34 . In addition, the charging body 51 and the plate electrode 55 are mounted at symmetrical positions with respect to the in-mold foil H. As shown in FIG.

[0057] Also in the in-mold forming device 60 thus constituted, the same effects as those possessed by the above-mentioned in-mold formi...

no. 3 example

[0059] Figure 11 It is a perspective view schematically showing an in-mold forming device 70 according to a third embodiment of the present invention. exist Figure 11 use the same notation in the figure 2 The same functional parts shown in , and its detailed description is omitted.

[0060] In the aforementioned in-mold forming device 20 of the first embodiment and the in-mold forming device 60 of the second embodiment, the in-mold foil feeding mechanism 40 is installed only in the vertical direction. However, in the in-mold forming device 70 of the present embodiment, the in-mold foil feeding mechanisms 40 are arranged one after the other in the vertical direction and the horizontal direction. Therefore, the in-mold forming device 70 can realize composite in-mold forming in which the in-mold foils H are arranged in the vertical direction and the horizontal direction.

[0061] In addition, chargers 50 are respectively installed on the respective sides of the foil feeder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com