Polarization light emitting apparatus for light orientation

An irradiation device and a technology of light irradiation, applied in polarizing elements, optics, nonlinear optics, etc., can solve problems such as difficult to use and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

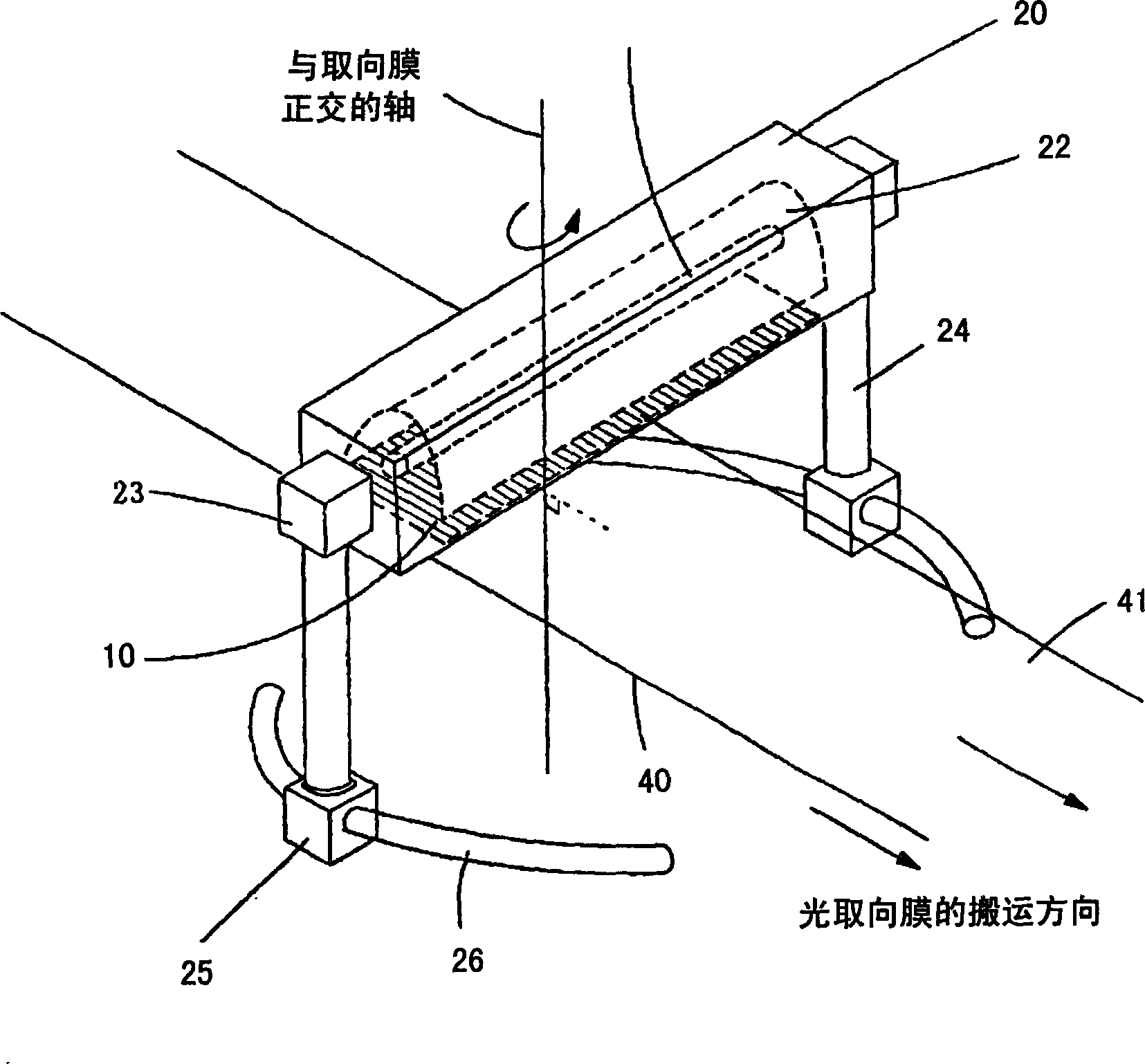

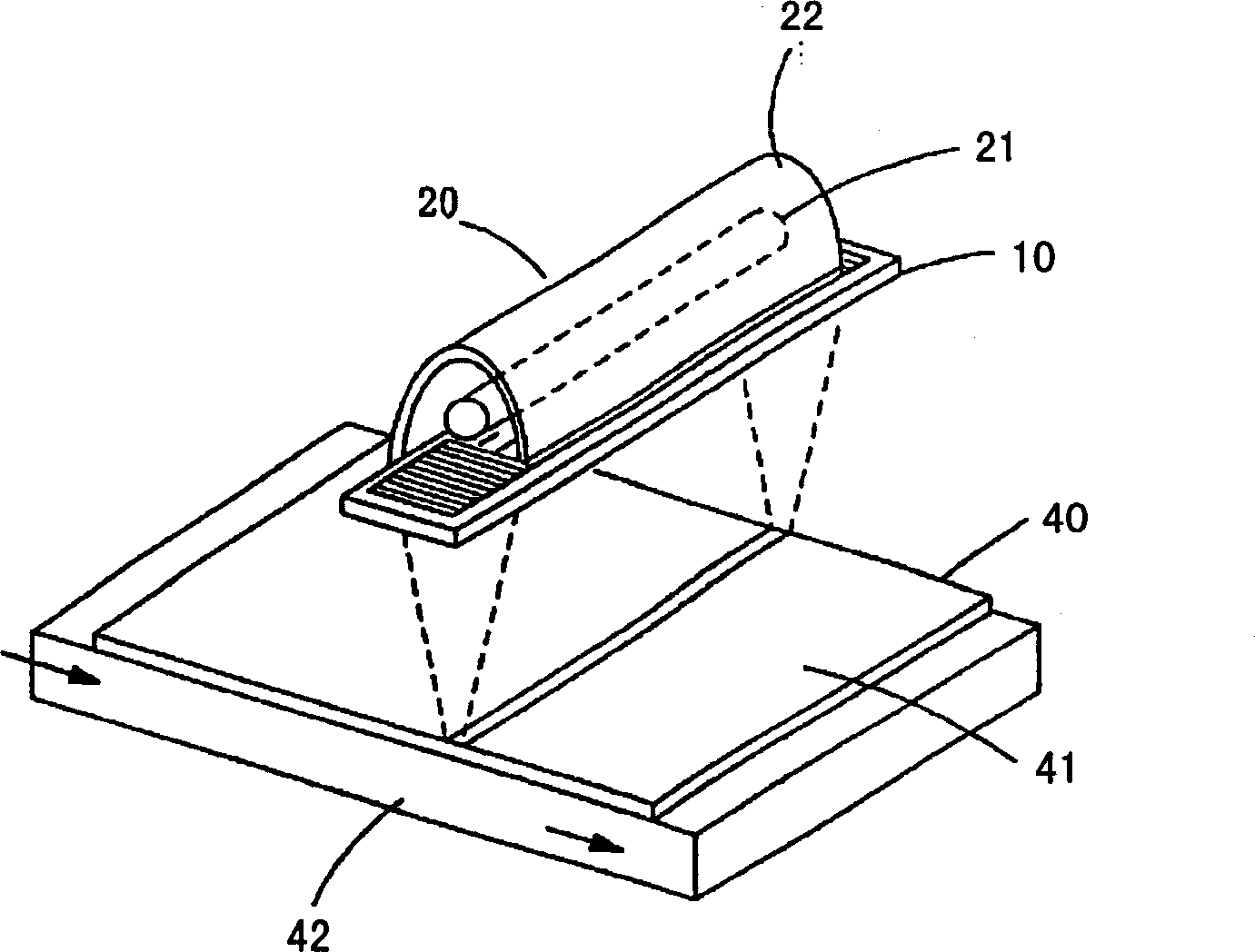

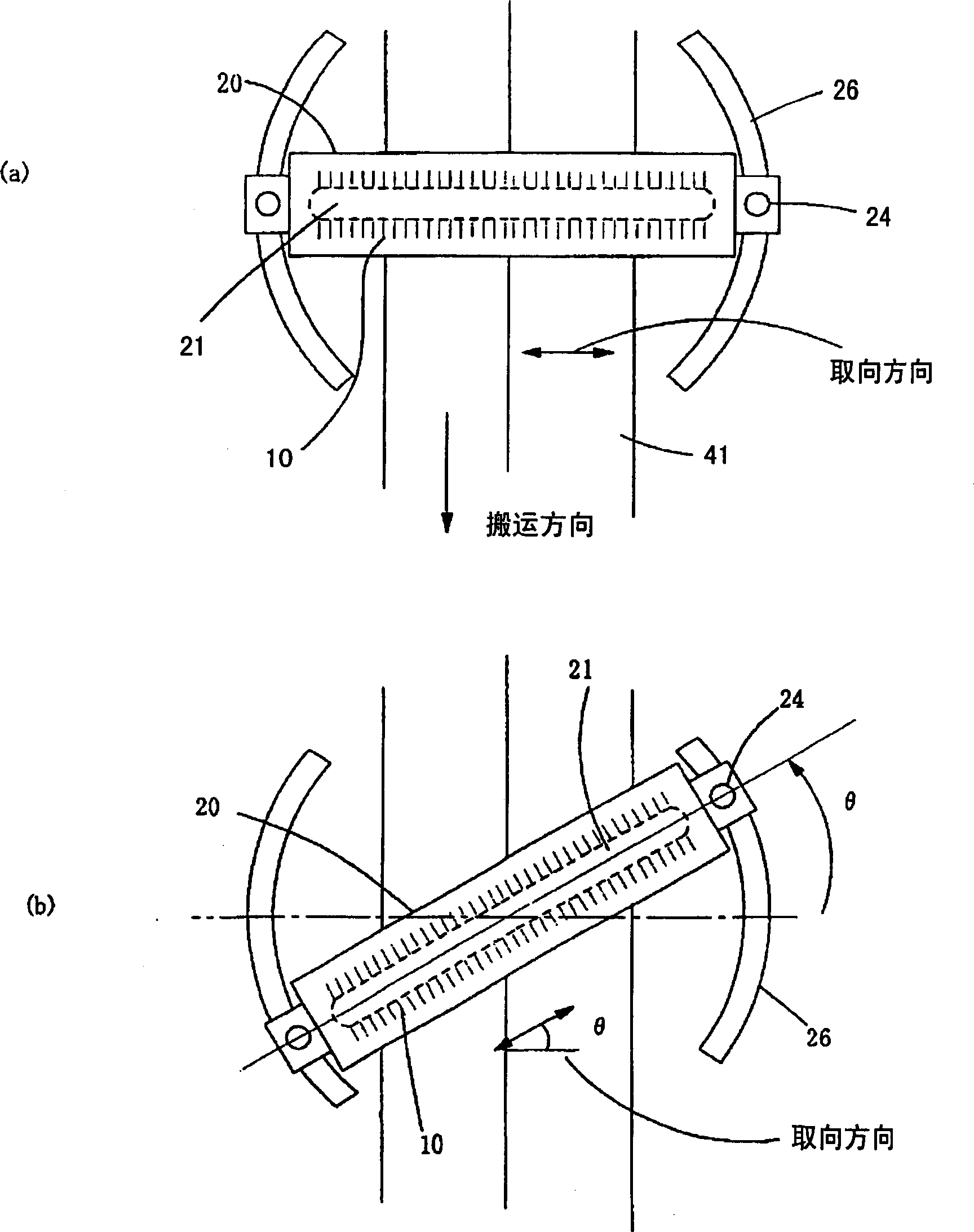

[0064] figure 1 It is a figure which shows the structure of the polarized-light irradiation apparatus of the Example of this invention.

[0065] Such as figure 1 shown, with Figure 15 A rod-shaped lamp 21 , which is also a linear light source such as a high-pressure mercury lamp or a metal halide lamp, and a sink-shaped condenser lens 22 that reflects light from the lamp 21 are incorporated in the light irradiation unit 20 . Furthermore, a wire grid polarizing element 10 is provided on the light exit side.

[0066] In addition, rod lamps are described below as linear light sources as examples, but LEDs and LDs that emit ultraviolet light have also been put into practical use in recent years, and such LEDs or LDs can be arranged in a straight line as a linear light source. In addition, in this case, the direction in which LEDs or LDs are arranged corresponds to the longitudinal direction of the lamp.

[0067] In addition, as the material of the photo-alignment film at pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com