Envelope follower end point detection in time division multiplexed processes

A technology of time-division multiplexing and alternate processing, applied in vacuum gauges using ionization effects, semiconductor/solid-state device testing/measurement, semiconductor/solid-state device manufacturing, etc., can solve problems such as not providing advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

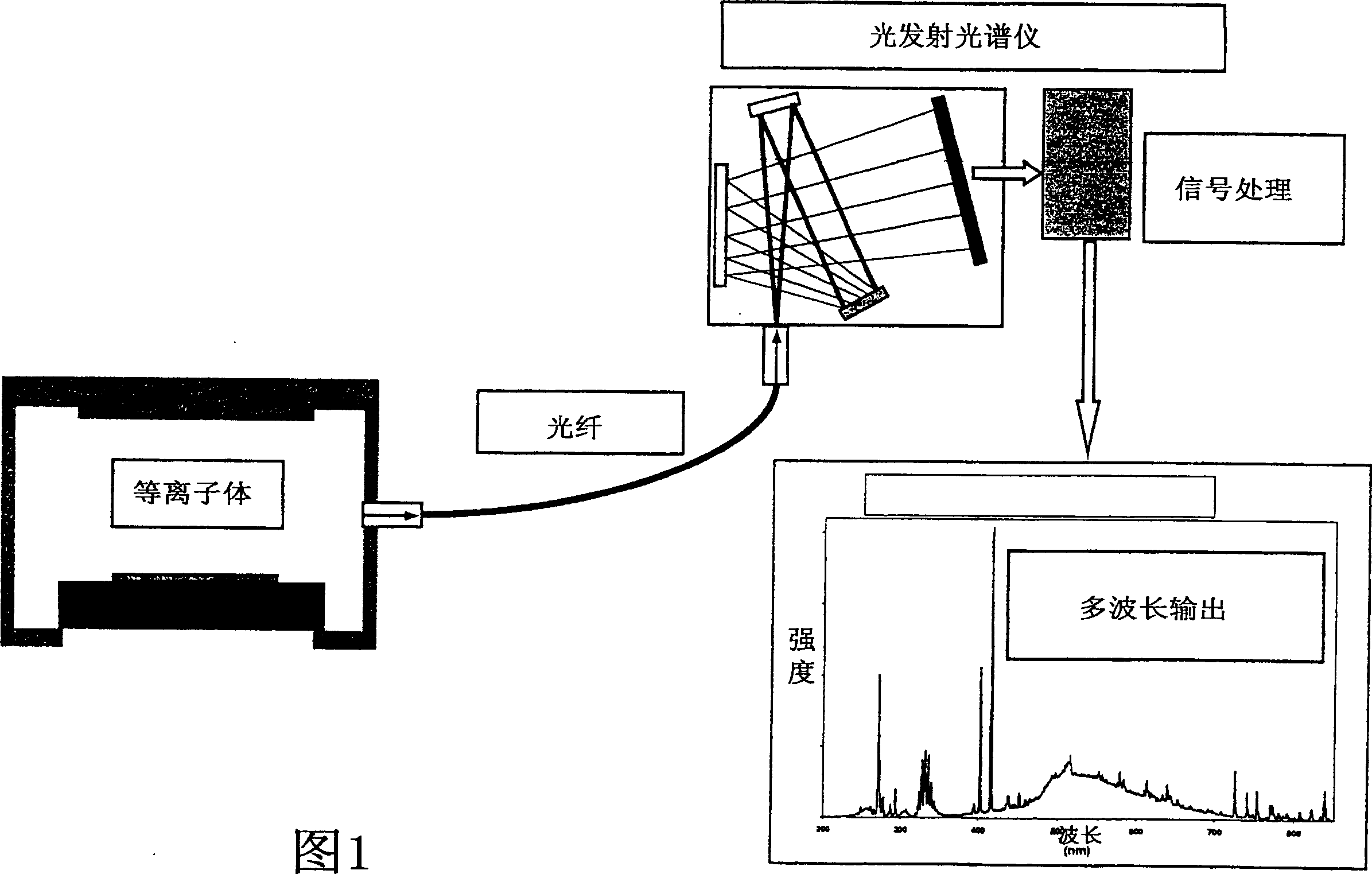

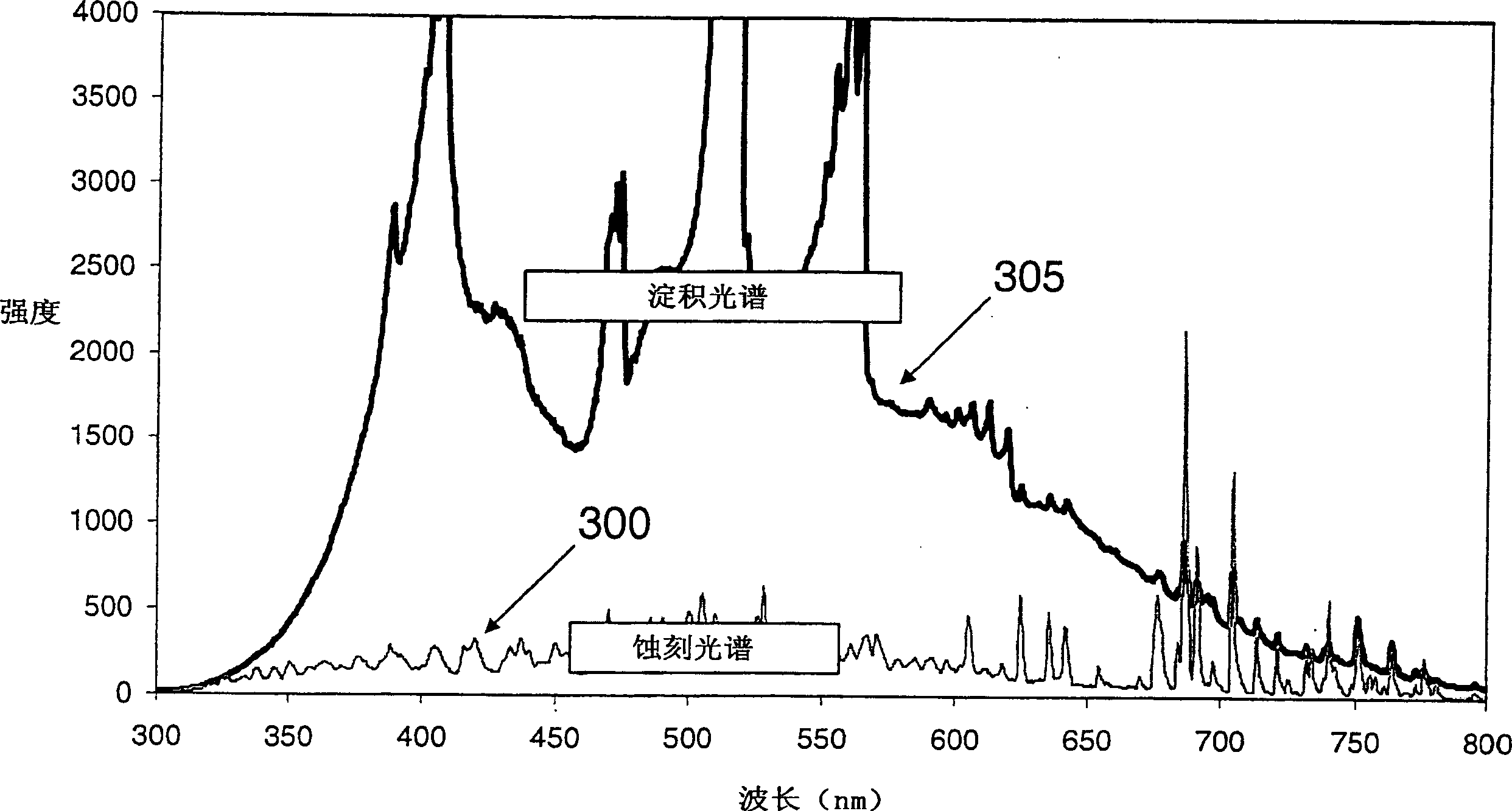

[0053] We disclose a method for detecting transitions between different materials in a time-division multiplexed (TDM) process by analyzing the intensity of at least one wavelength region emitted by the plasma without synchronous triggers.

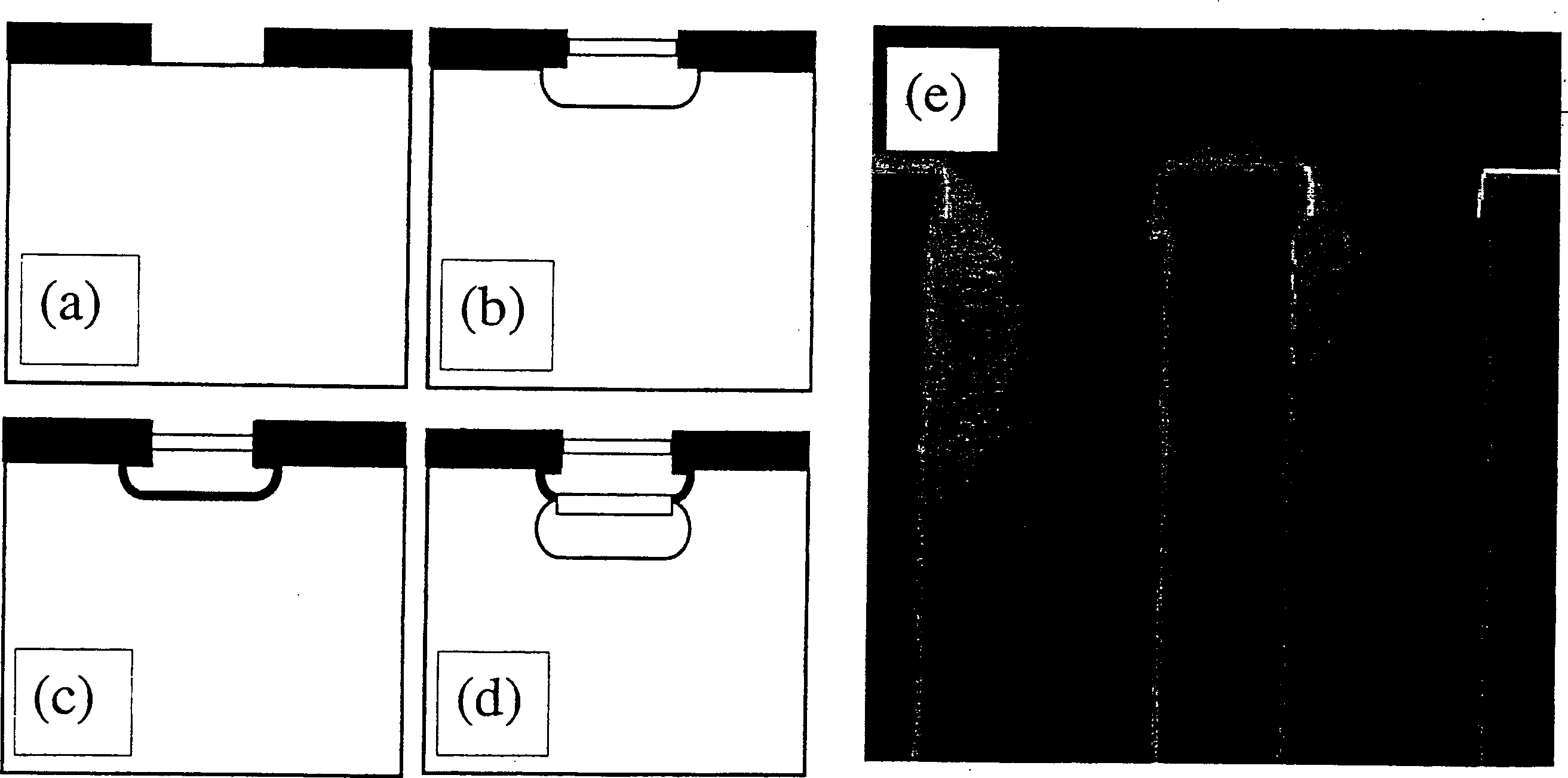

[0054] Due to the periodic and repetitive nature of the TDM process, by design, the process has multiple characteristic frequencies associated with it. As an example, consider a two-step TDM silicon etch process consisting of a five-second etch step followed by a five-second deposition step repeated multiple times in sequence (see Table 1 below). One characteristic frequency determined by the total cycle time (10 seconds) is 0.1 Hz.

[0055] processing parameters

Units of measurement

deposition

etching

SF 6 flow

sccm

0.5

100

C 4 f 8 flow

sccm

70

0.5

Ar flow

sccm

40

40

pressure

mTorr

22

23

RF bias power

W

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap