Optical switch and making method thereof

A manufacturing method and technology of optical switches, which are applied in optics, optical components, nonlinear optics, etc., can solve the problems of low light transmittance of liquid crystal optical switches, difficulty in improving the brightness of projection display equipment, etc., so as to avoid light energy from being absorbed, The effect of high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with accompanying drawing.

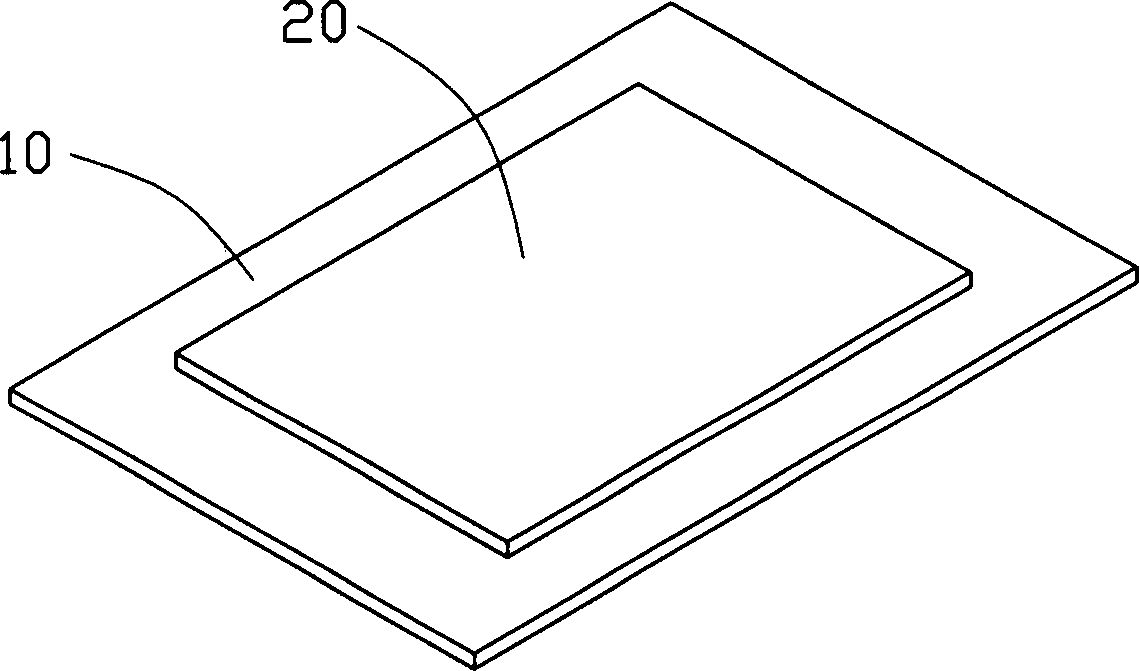

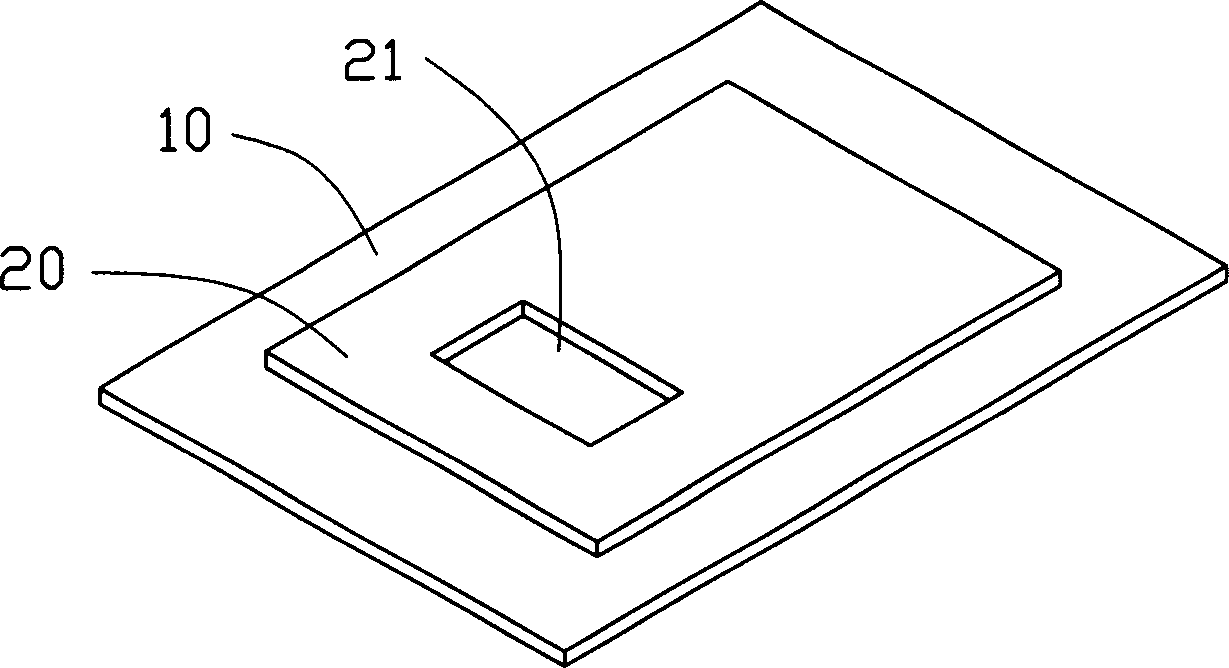

[0038] see Figure 7 , the optical switch 100 provided by the present invention, which includes: a substrate, which includes a transparent substrate 10, and a light shielding layer 20 formed on the transparent substrate 10, the light shielding layer 20 has a first through hole 21; And a comb-shaped driving structure matched with the above-mentioned substrate, which includes a first comb-shaped electrode and a second comb-shaped electrode. The first comb electrode includes a first side wall 43 , and a first top surface 41 extending from the other end of the first side wall 43 opposite to the contact end of the transparent substrate 10 . The first top surface 41 is located on the transparent substrate 10 and is substantially parallel to the transparent substrate 10. A second through hole 410 and a plurality of first interdigitated structures 411 are formed on the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com