Automatic processing system and method before optical membrane plate package

A processing method and processing system technology, applied in the field of automatic processing systems, can solve problems such as inconsistent quality, film peeling, and failure to meet the rapid trend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

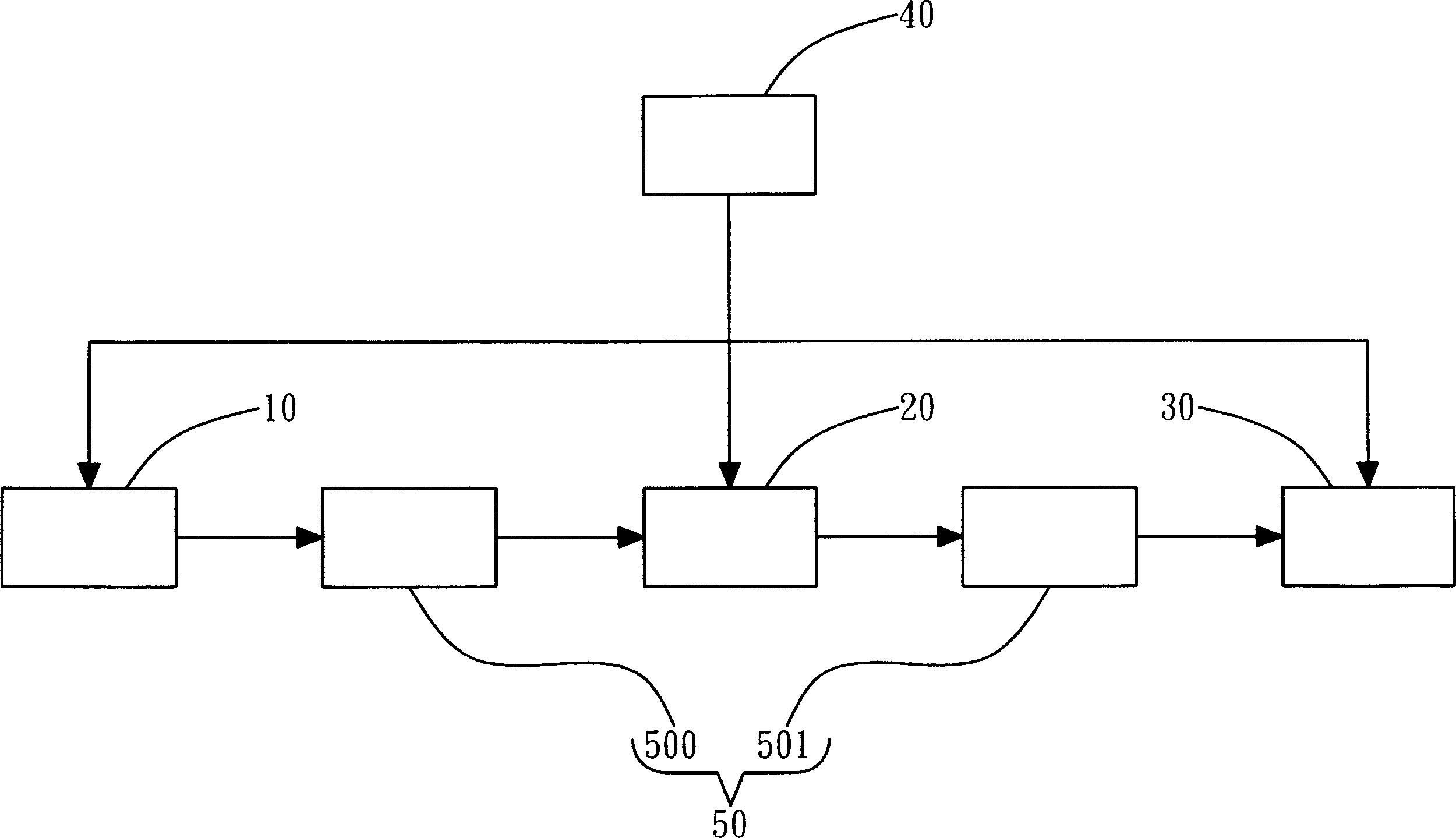

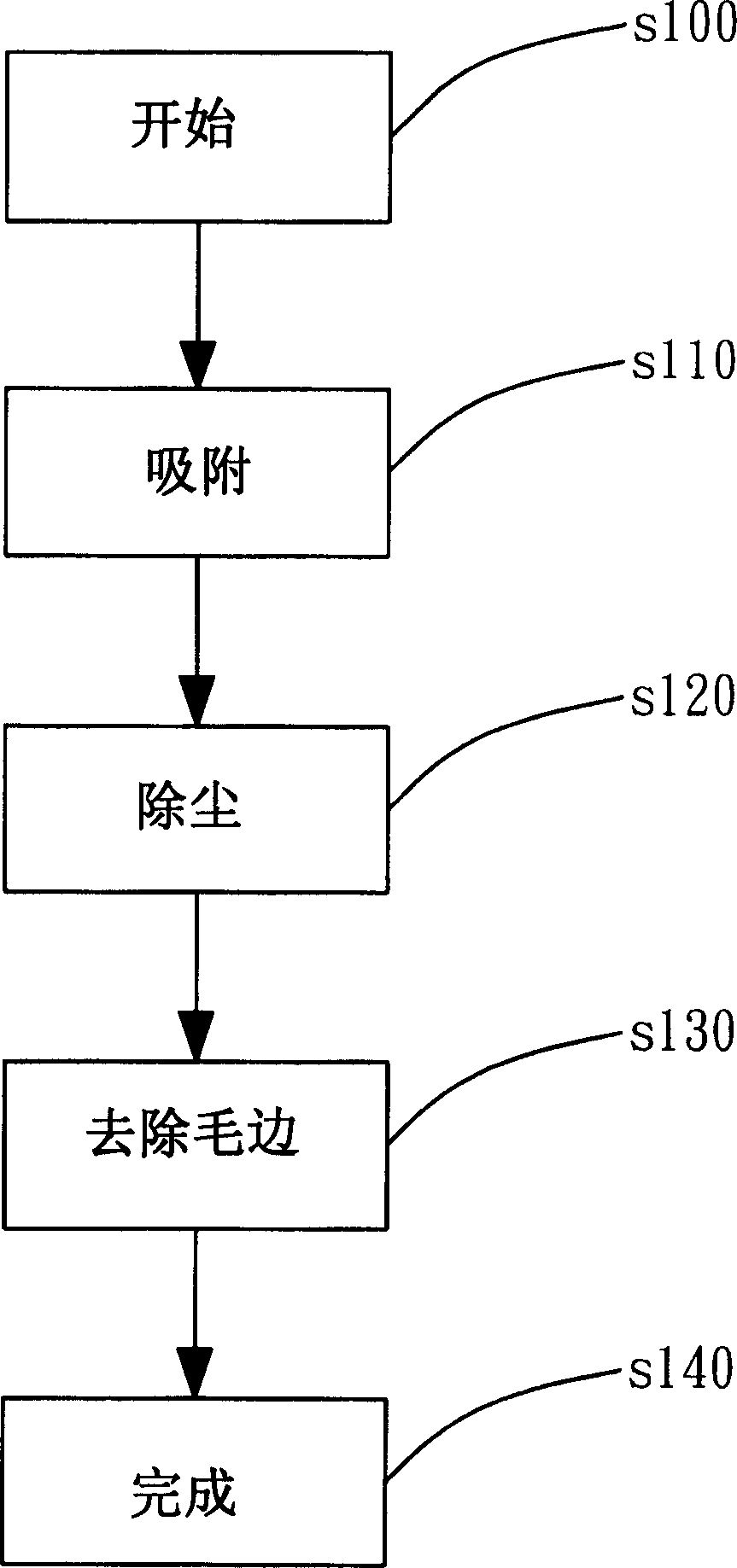

[0012] See figure 1 and figure 2 As shown, figure 1 Is a schematic diagram of the architecture of the present invention, figure 2 It is a flowchart of the steps of the present invention. The present invention is an automatic processing system and method for optical film board before packaging, which includes:

[0013] A suction device 10, which sucks and moves an optical film plate (not shown in the figure), and uses the suction device 10 to move the optical template smoothly during the overall movement process, and it is not easy to bend, twist, etc. , In order to avoid the phenomenon of peeling of the film on the optical template during the moving process, resulting in defective products;

[0014] A dust removal device 20 mainly removes impurities adhering to the surface of the optical film to facilitate subsequent processing on the surface of the optical template, and the dust removal device 20 is used to replace manual dust removal procedures, and the quality of the optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com