Combination system for servo-roll-separating and quick-backward of cross-roll straightening machine

A straightening machine roll and combination system technology, which is applied in the field of roll gap adjustment device and rapid opening and pressing oil cylinder of the roll gap, can solve the problem that the dynamic straightening force and reliable detection of the roll gap cannot be dynamically adjusted online, and the roll gap cannot be satisfied. issues such as rapid change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

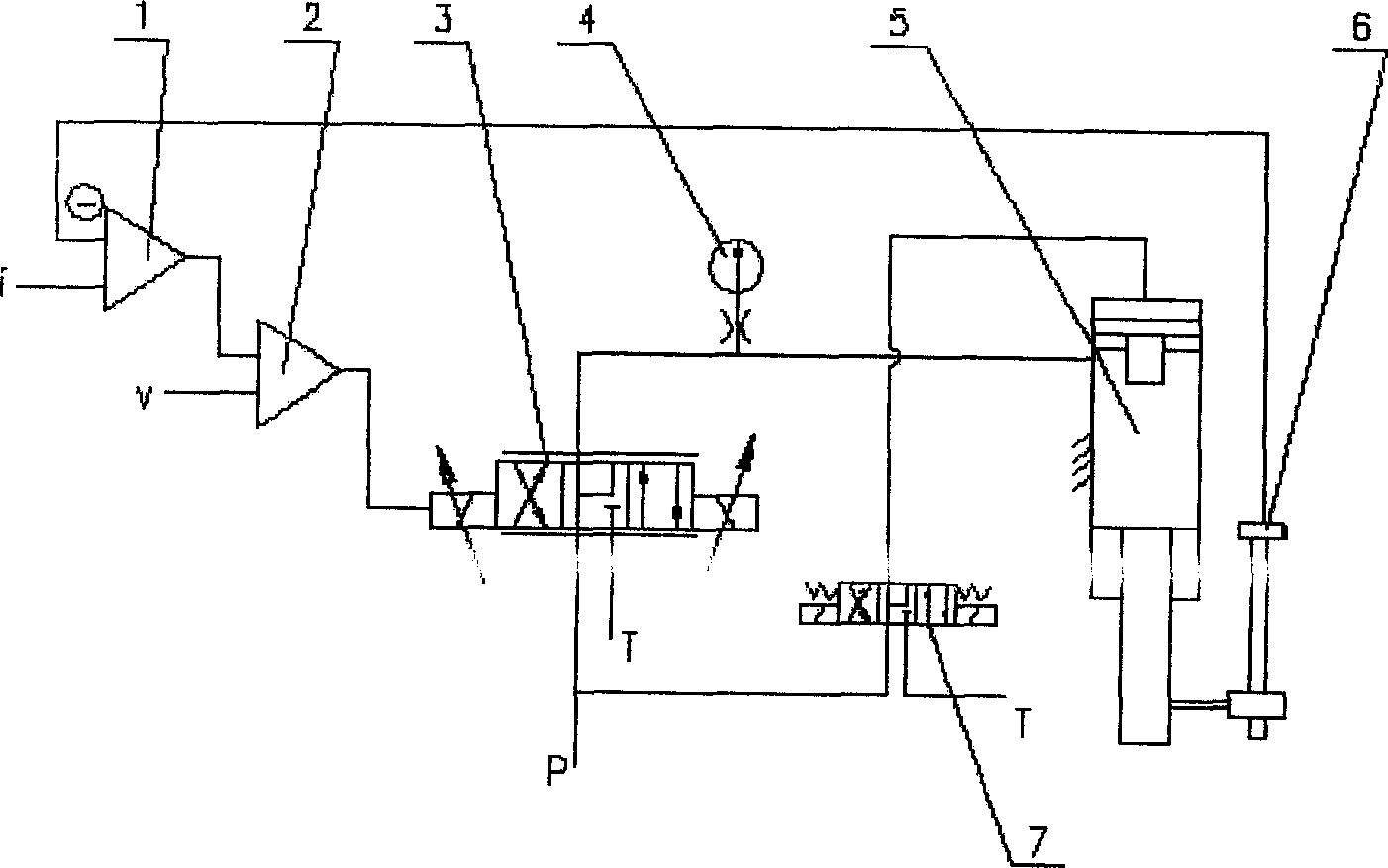

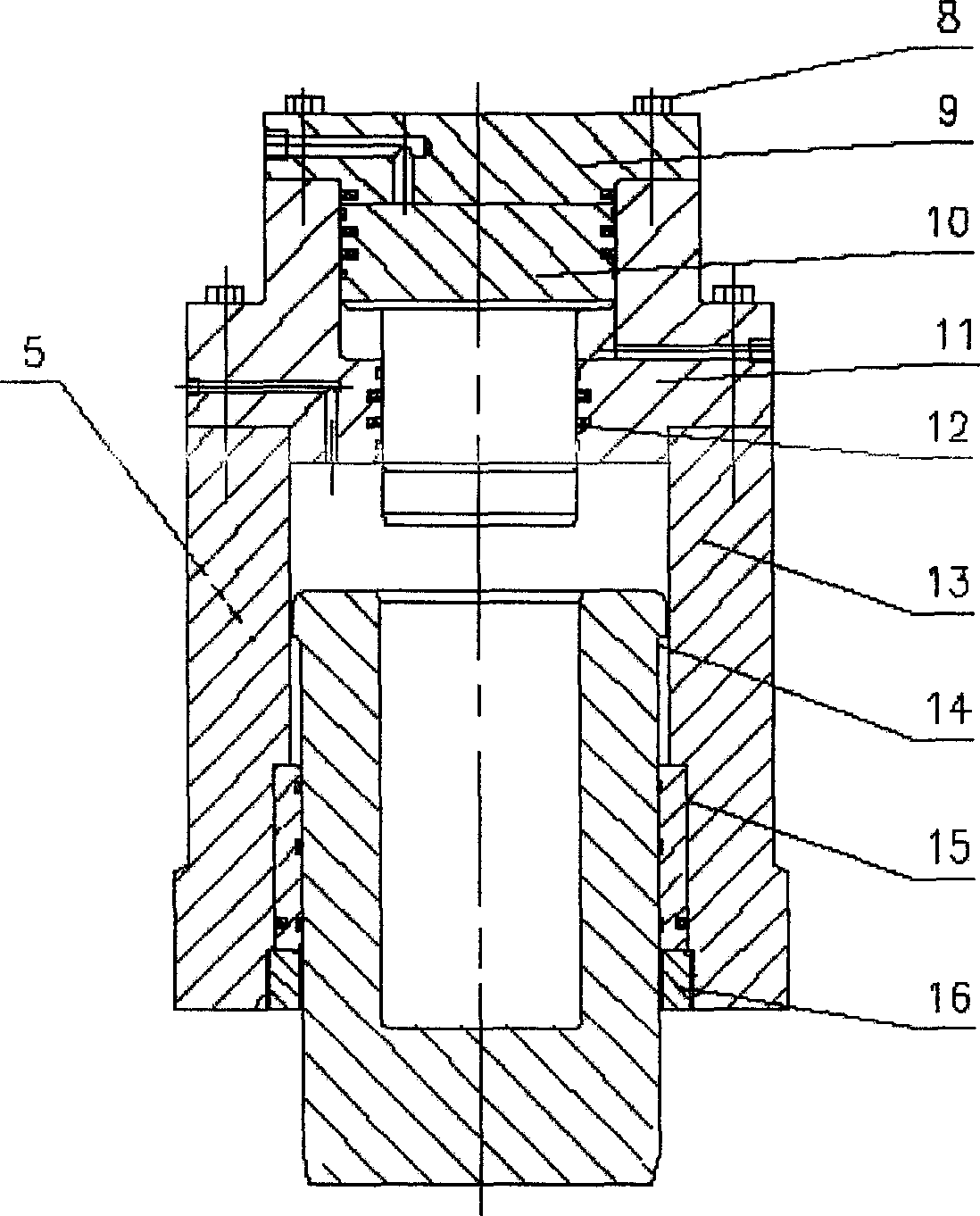

[0009] Depend on figure 1 It can be seen that when the skew roll leveler adjusts the roll gap of the straightening roller, after the electrical control system sends out the command (i) of the roll gap movement, the roll gap control circuit (1) in the PLC receives the roll gap adjustment command After (i), the instruction is amplified by the servo valve control amplifier (2) to drive the servo valve (3) to act, and the pressure oil of the hydraulic system enters (or flows out) the roller through the P port (or T port) and through the servo valve (3) The seam servo surveys the fast-reverse cylinder (5), and the plunger of the servo cylinder moves out (or retracts), and the displacement of the plunger is detected and fed back by the displacement sensor (6) connected with the cylinder plunger In the roll gap control circuit (1), after comparing with the received roll gap adjustment command (i), when the compared difference reaches the displacement accuracy set by the system, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com