Underwater dry-type repairing work cabin

A maintenance work, dry technology, applied in underwater operation equipment, pipeline laying and maintenance, ships, etc., can solve problems such as complex sea conditions, hollowing out, economic and construction effects are not very ideal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

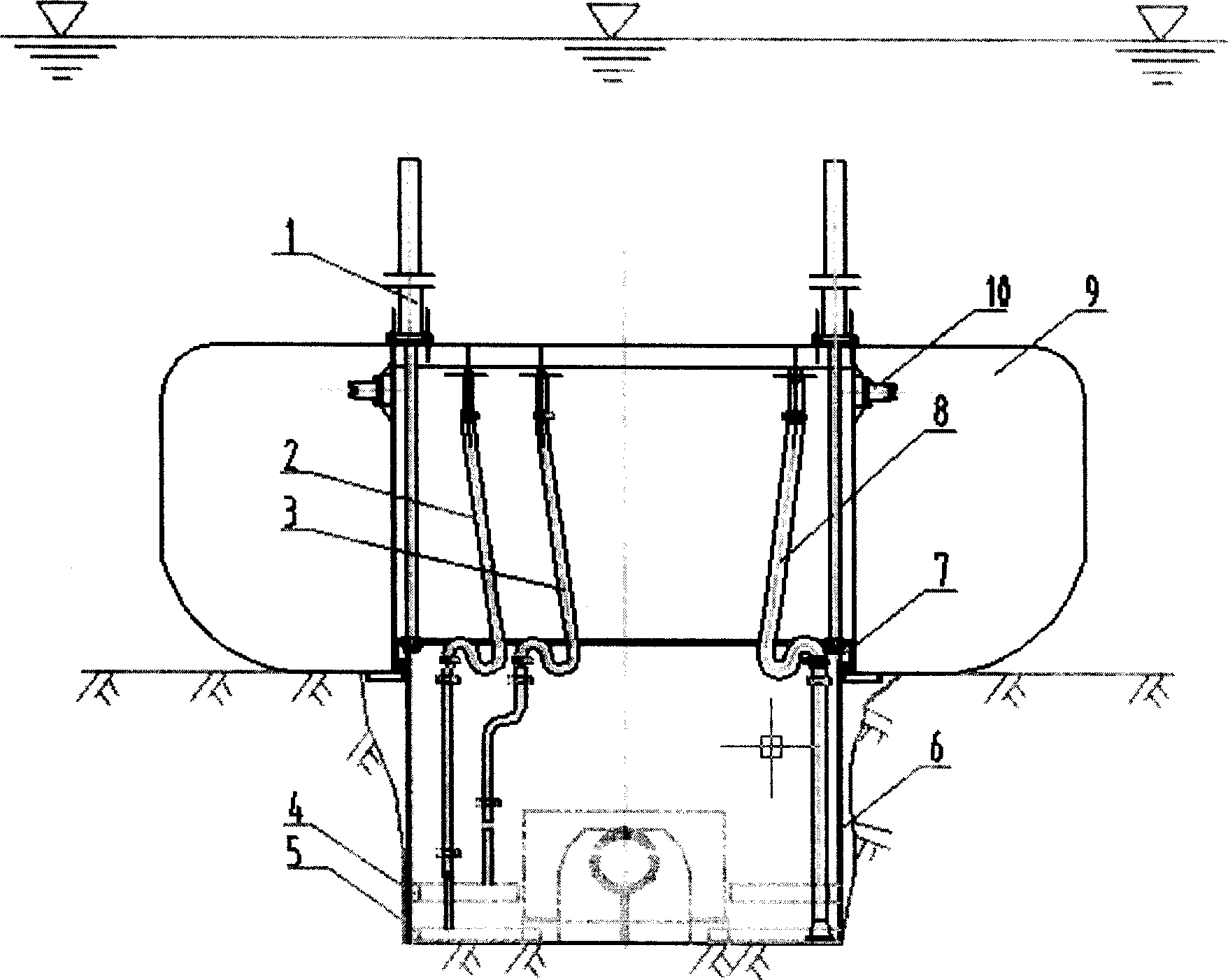

[0011] Now combined with the manual figure 1 The present invention is described further:

[0012] 1. The sinking operation of the maintenance cabin:

[0013] After the submersible 9 that the underwater dry maintenance work cabin is housed is driven to the predetermined working position and sits on the bottom and positioned, the sinking operation starts. First open the positioning device 10 to make the maintenance work cabin in a free state, then turn on the vertical jetting pump in the submersible 9, and the high-pressure water flows through the vertical jetting main pipe 2 to the vertical jetting device 5 for vertical jetting, and the maintenance cabin is 6 times After inserting to a certain depth, turn on the horizontal jetting pump and the suction pump in the submersible 9, and the high-pressure water flows through the horizontal jetting main pipe 3 to the horizontal jetting device 4, so that the silt at the bottom of the working cabin forms a mud swirl, and passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com