Jet fluid bundled propeller

A propeller and fluid technology, applied in the directions of rotary propellers, ship propulsion, propulsion components, etc., can solve the problems of unusable tubes, inability to solve, and entanglement of debris, so as to improve the entanglement of debris or collision damage, Small bubble friction, saving maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

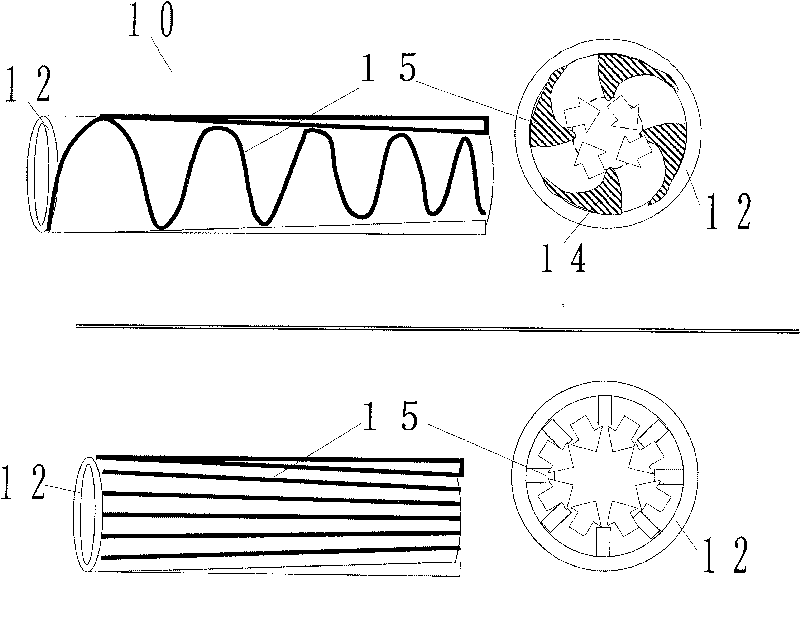

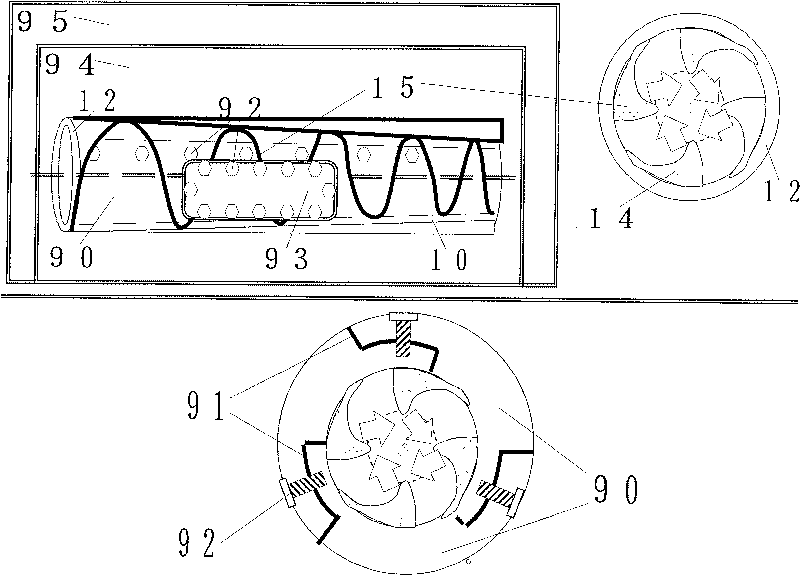

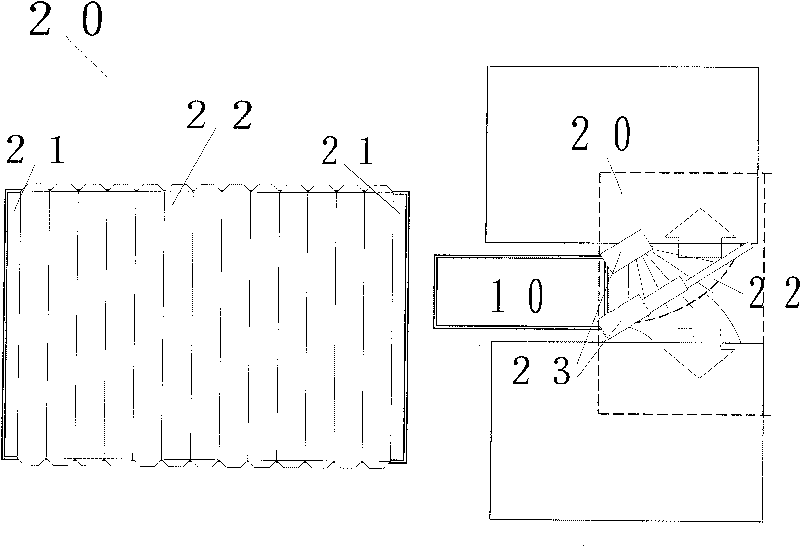

[0194] Please refer to figure 1 , Is a schematic diagram and a cross-sectional view showing the diversion and cluster hollow tube of the fluid jet cluster thruster 100 of the present invention. The inner diameter of the diversion cluster hollow tube 10 is wide in the front and narrow in the rear to enhance the bundling effect at the center of the hollow tube 10 when the fluid passes through, as shown by the dotted line; the tube wall 12 has one or more inner wall diversion tubes Protruding piece 15. In an embodiment of the present invention, the guide fins 15 on the inner wall of the tube are spiral, which are used to generate a spiral cluster fluid at the center of the tube when the guide bundle hollow tube 10 is rotated; One or more ribs 14 are provided on the surface of the guide tab 15 to enhance the kink and bundling force when the fluid passes. In another embodiment of the present invention, the guide fins 15 on the inner wall of the tube are linear, and are used to gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com