Mechanical cement slurry vibration tester

A technology of vibration test and cement slurry, which is applied in the direction of ceramic molding machine, material inspection product, investigation stage/state change, etc., and can solve the problems of inability to control temperature, inability to continuously change vibration frequency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

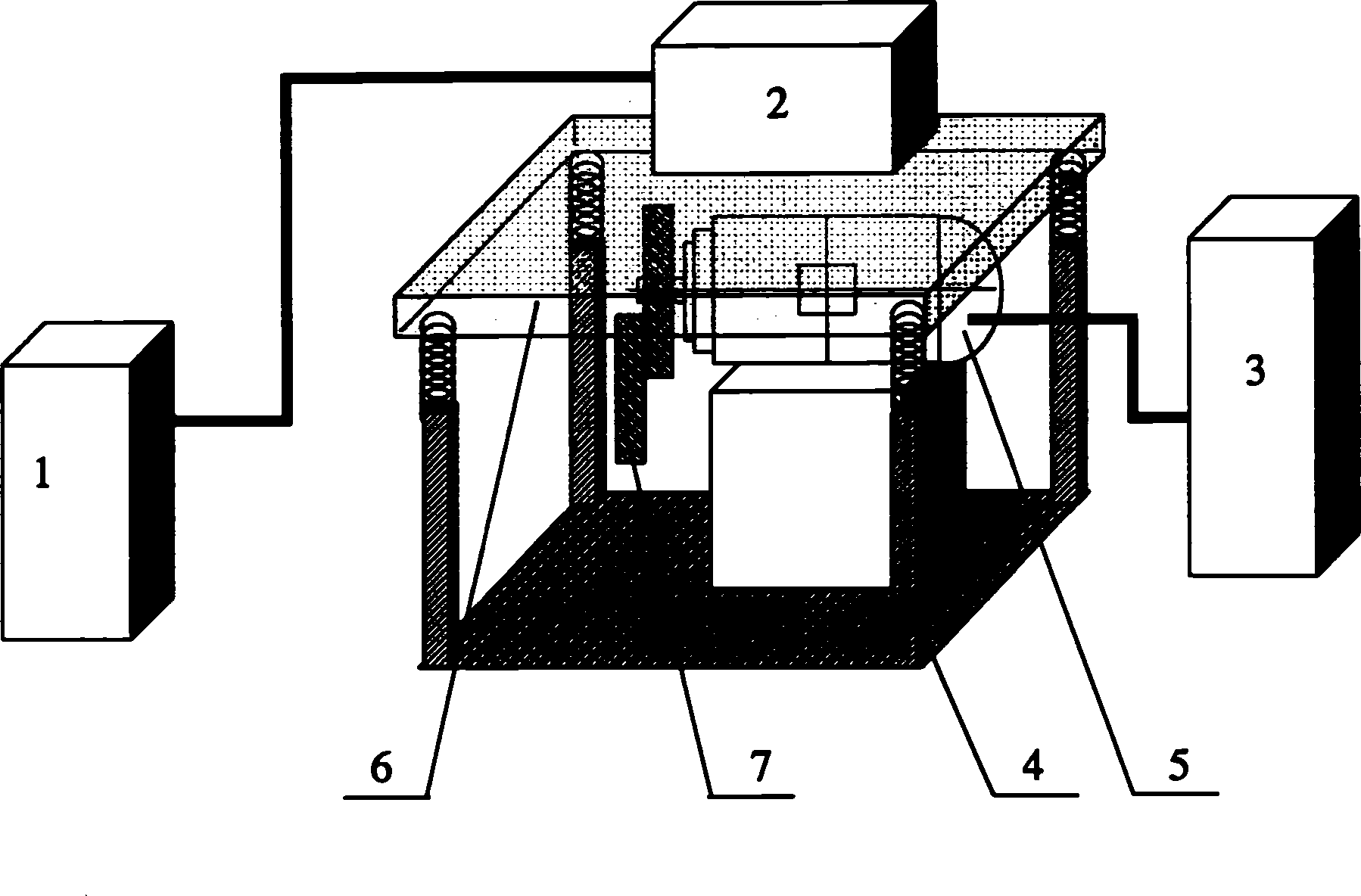

[0014] The specific implementation of the mechanical cement slurry vibration tester of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] figure 1 It is a schematic diagram of the connection of various components of the mechanical cement slurry vibration tester. In the figure, the lower end of the anti-seismic base 4 is fixed on the ground through anchor bolts, and the upper end supports the vibrating platform 2 through springs. The spring on the anti-seismic base 4 pulls the vibrating platform 2 against the top of the eccentric vibrator 7 . The bottom plane of the vibrating platform 2 is in contact with the outer peripheral upper surface of the eccentric vibrator 7 . The eccentric vibrator 7 is vertically fixed on the main shaft of the adjustable speed motor 5 with its axis center, and the adjustable speed motor 5 is connected with the frequency converter 3 through a circuit. The vibration platform 2 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com