Pneumatic tire

A technology for pneumatic tires and tires, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc. It can solve problems such as deterioration of turning performance, rapid wear of the outer side, and decline in tire high-speed durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A pneumatic tire comprising: a tread portion with a tread edge; a pair of axially spaced bead portions; and a pair of The sidewall portion so that the tire has a toroidal shape.

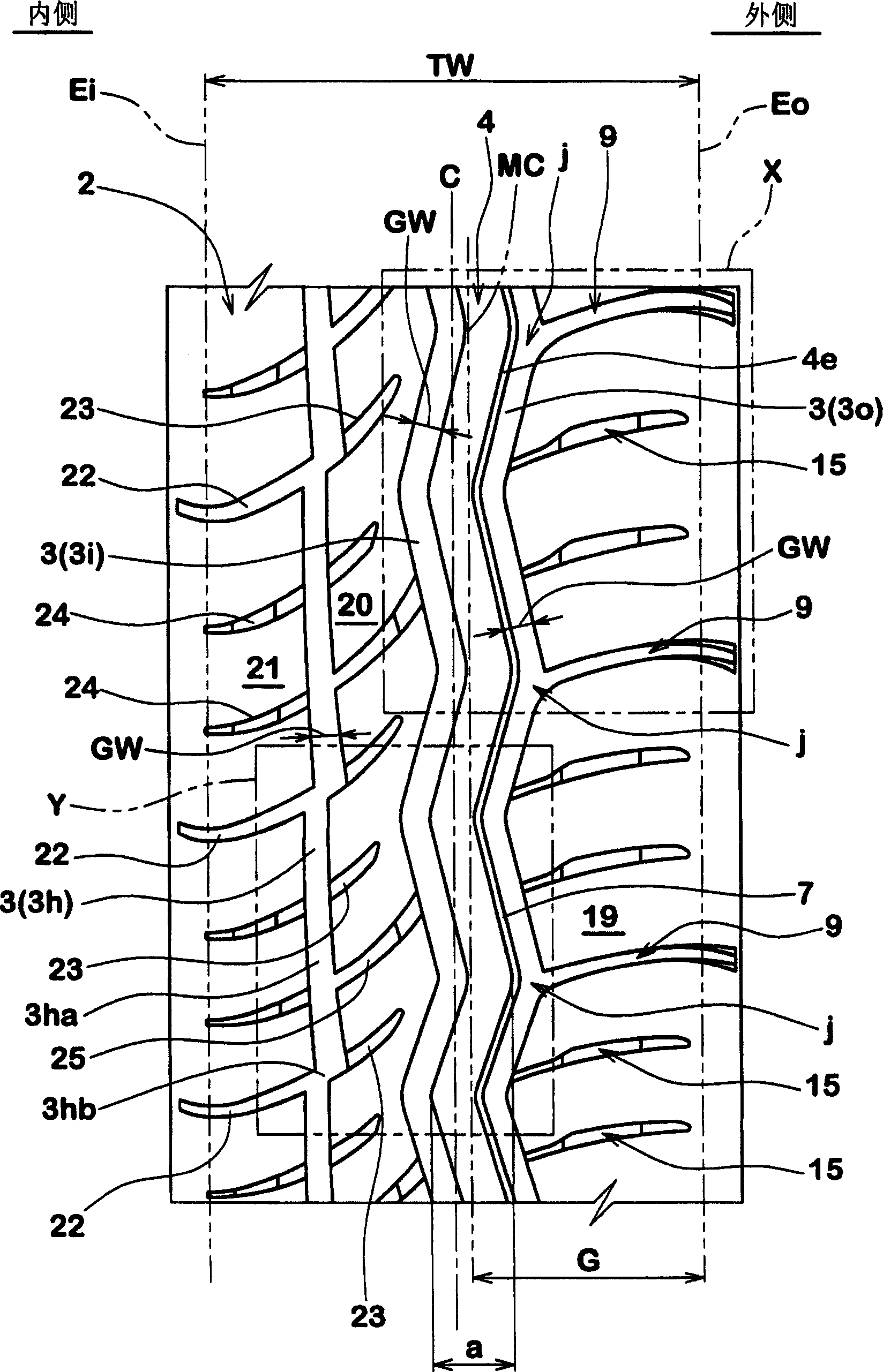

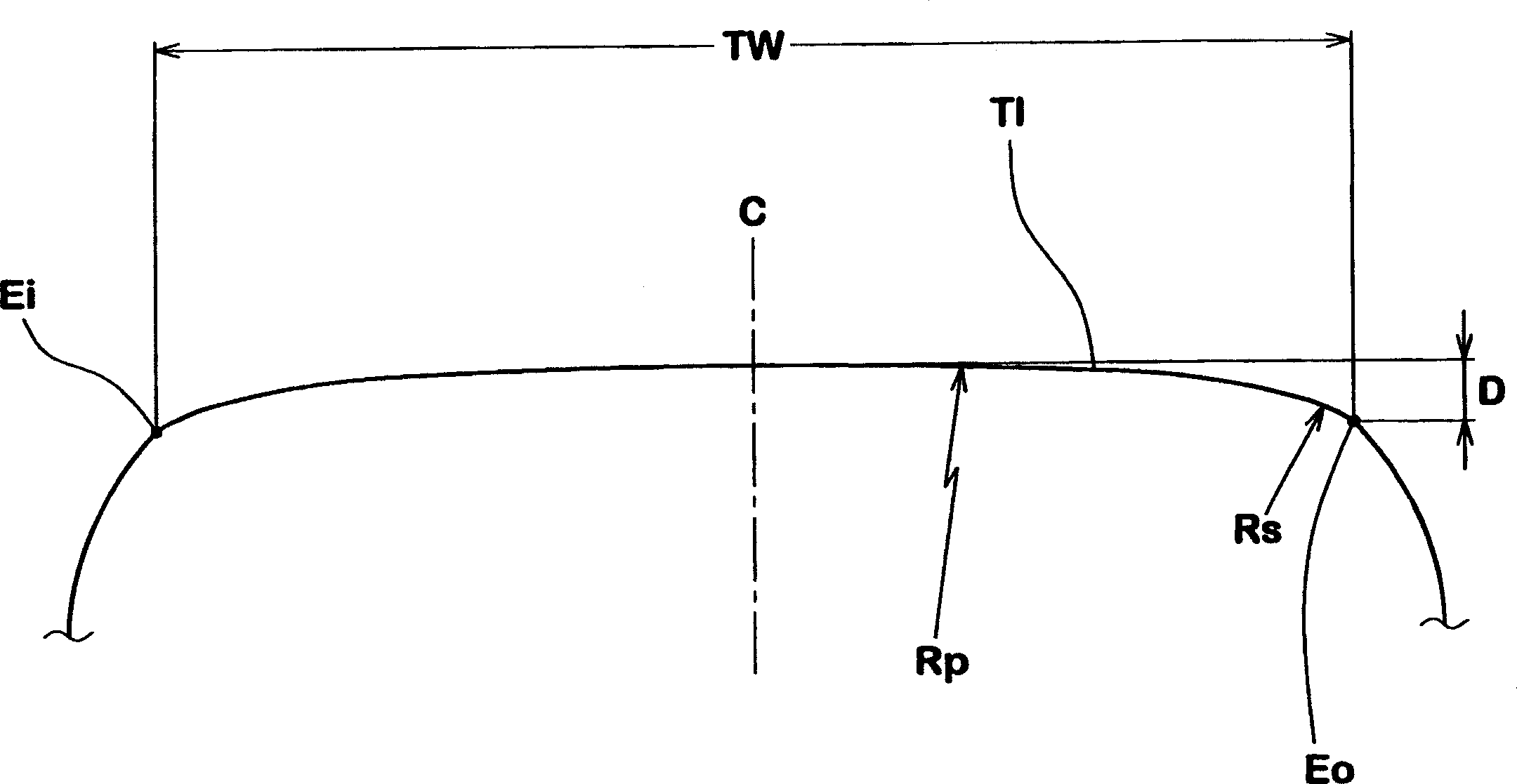

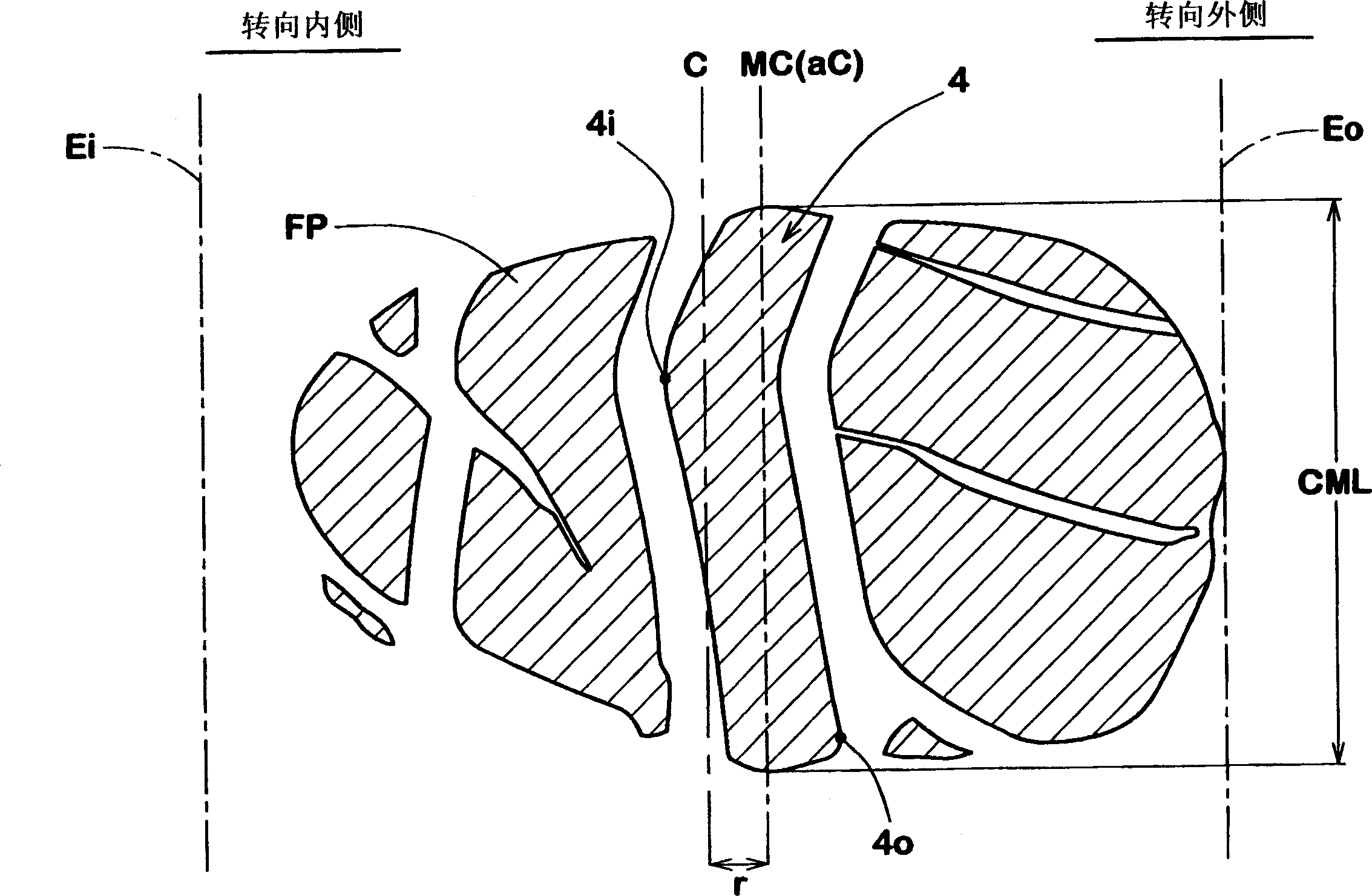

[0024] The pneumatic tire 1 according to the present invention is provided with tread grooves defining a tread pattern in a tread portion 2 which is also provided with a rounded profile T1. figure 1 and figure 2 An example of a tread pattern and an example of a tread profile T1 are shown in .

[0025] The tread pattern according to the present invention is asymmetrical with respect to the tire equator line C, and the position of the sidewall portion with respect to the vehicle is fixed. In other words, the tire must be mounted on the rim so that the tread edge Eo (hereinafter referred to as "outer tread edge Eo") is outside the vehicle, and accordingly the other tread edge Ei (hereinafter referred to as "inner tread edge Ei") on the inside of the vehicle. Thus, the tire may be provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com