Physical value sensor and lead frame for use therein

A technology of physical quantity sensor and lead frame, applied in the field of lead frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

[0139] Next, a second embodiment of the present invention will be described with reference to Figs. 11-13. The lead frame and the magnetic sensor of the second embodiment are different from the first embodiment in the connection of the frame part and the table part. Here, only the connection part of the frame part and the stage part will be described, and the same reference numerals are used for the same parts as the components of the lead frame 1 or the magnetic sensor 30, and the description thereof will be omitted.

[0140] As shown in FIGS. 11 and 12, in the lead frame 2, the base portions 7 and 9 and the rectangular frame portion 13 are connected to each other by connecting wires (connecting portions) 16 protruding from the corners of the rectangular frame portion 13. The connecting wire 16 is formed to protrude a pair from each of the base portions 7 and 9 at a line symmetrical position passing through the central axis L2 of the base portions 7 and 9. Specifically, the one e...

no. 3 example

[0179] Next, the third embodiment of the present invention will be explained.

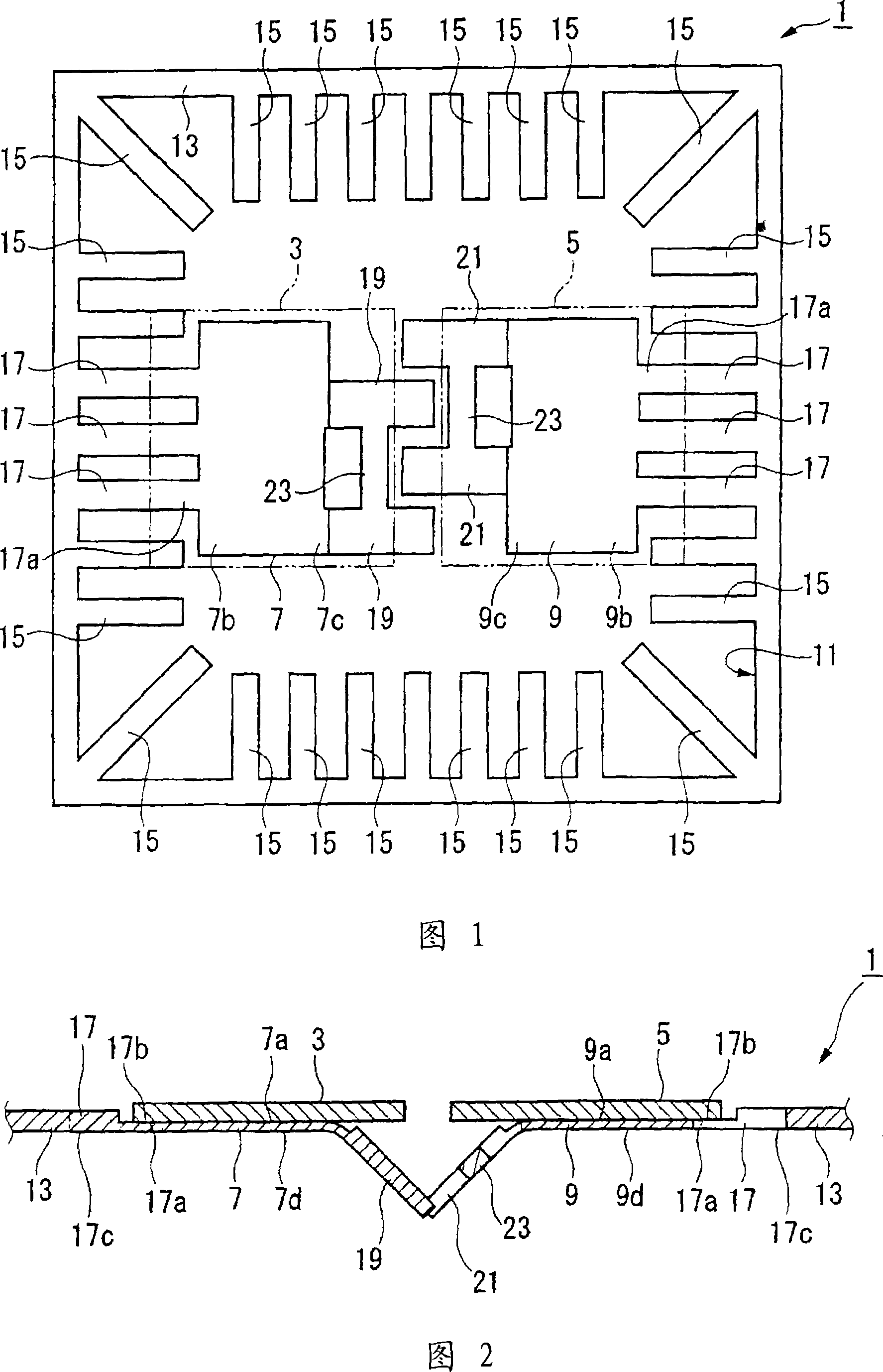

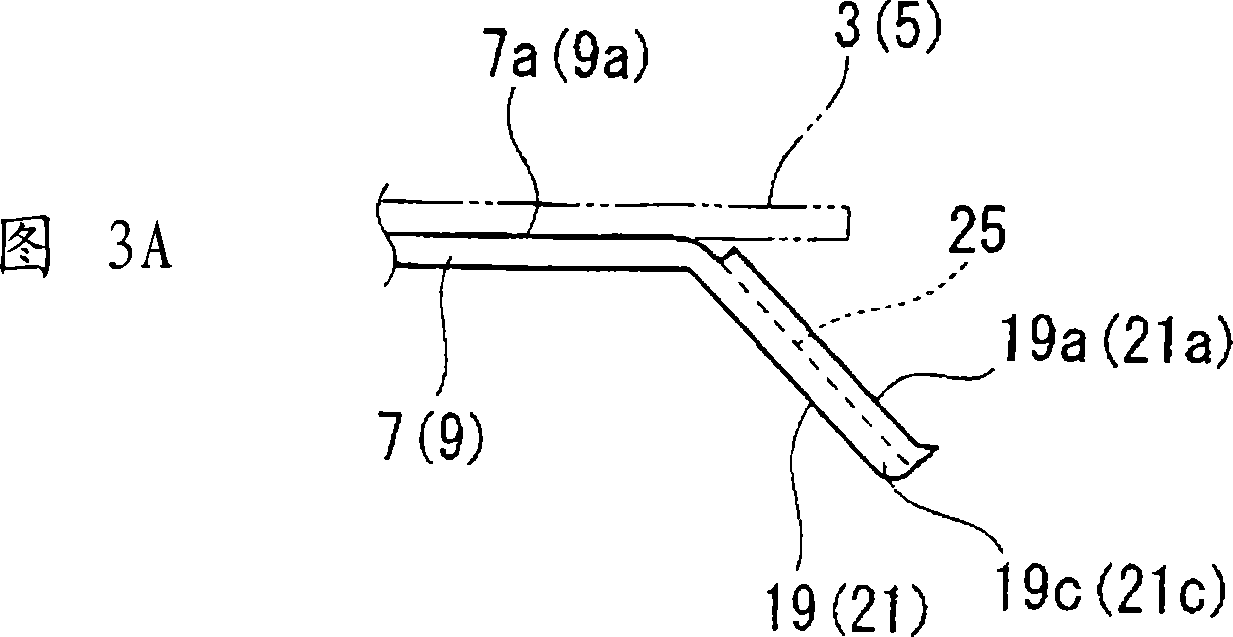

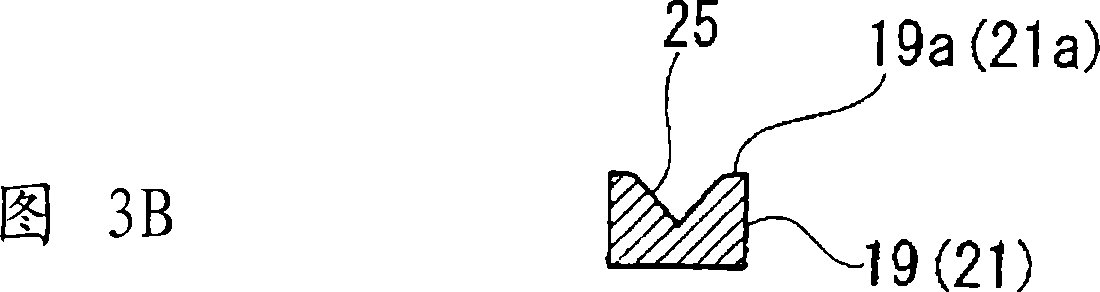

[0180] As shown in FIGS. 31 and 32, the lead frame 101 has two table portions 107, 109 for arranging magnetic sensor chips (physical quantity sensor chips) 103, 105 formed in a rectangular shape in plan view; frame portions supporting the table portions 107, 109 111; Connecting parts 119, 121 of the table parts 107, 109 and the frame part 111. These table parts 107 and 109, frame part 111, and connection parts 119 and 121 are integrally formed. The frame portion 111 has a rectangular frame portion 113 formed in a rectangular frame shape in plan view, which surrounds the table portions 107 and 109, and a plurality of lead wires 115 and 117 protruding inward from the rectangular frame portion 113. The connecting portions 119 and 121 connect the respective base portions 107 and 109 and the lead wires 117 (three wires each in this embodiment).

[0181] The lead wires 115 and 117 are electrically connected ...

no. 4 example

[0226] Figures 40 to 45 show the fourth embodiment of the present invention. The magnetic sensor (physical quantity sensor) of this embodiment is the same as the above-mentioned embodiment. The direction and magnitude of the external magnetic field are measured by two magnetic sensor chips inclined to each other. It is manufactured by a lead frame formed by press processing or etching processing.

[0227] The lead frame 201, as shown in FIGS. 40 and 41, has two table portions 207, 209 on which magnetic sensor chips (physical quantity sensor chips) 203, 205 formed in a rectangular shape in plan view are mounted; frames supporting the table portions 207, 209部211. These table parts 207 and 209 and the frame part 211 are integrally formed. The frame portion 211 is composed of the following components, surrounds the table portions 207 and 209, and is formed as a rectangular frame portion 213 having a substantially square frame portion in plan view; from each side 213a to 213h of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com