Cooling starting valve structure in fuel battery vehicle

A fuel cell, cold start technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as the need for thawing time and the consumption of thawing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

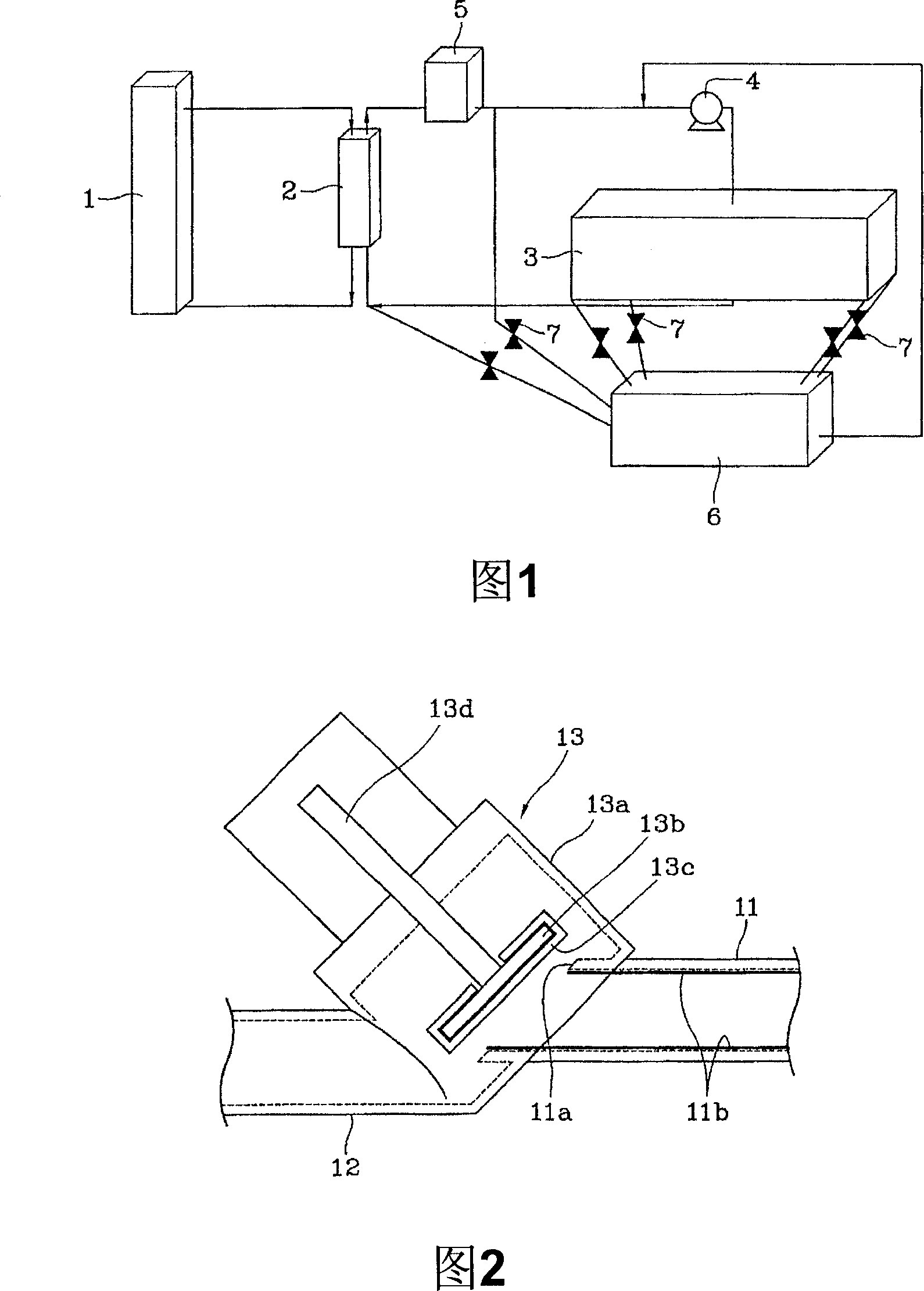

[0017] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

[0018] Fig. 2 shows a section of a cold start valve for a fuel cell vehicle according to the present invention. That is, the inlet pipe 11 and the outlet pipe 12 are arranged parallel to each other. The inlet pipe 11 is connected to a second cooling path of cooling water which circulates from the fuel cell stack through the heat exchanger and cools the fuel cell stack. The discharge pipe 12 is connected with the quick thawing device. The two pipes 11 and 12 are connected to communicate with each other through a valve body 13 a of a cold start valve 13 .

[0019] The two tubes are arranged parallel to each other. Therefore, in order to open or close the inlet pipe 11, the outlet of the inlet pipe 11 is cut to have an oval shape, thereby forming the oval valve seat 11a. The valve seat 11a is connected to and communicates with the valve body 13a....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com