Initiating device for an electronic detonator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

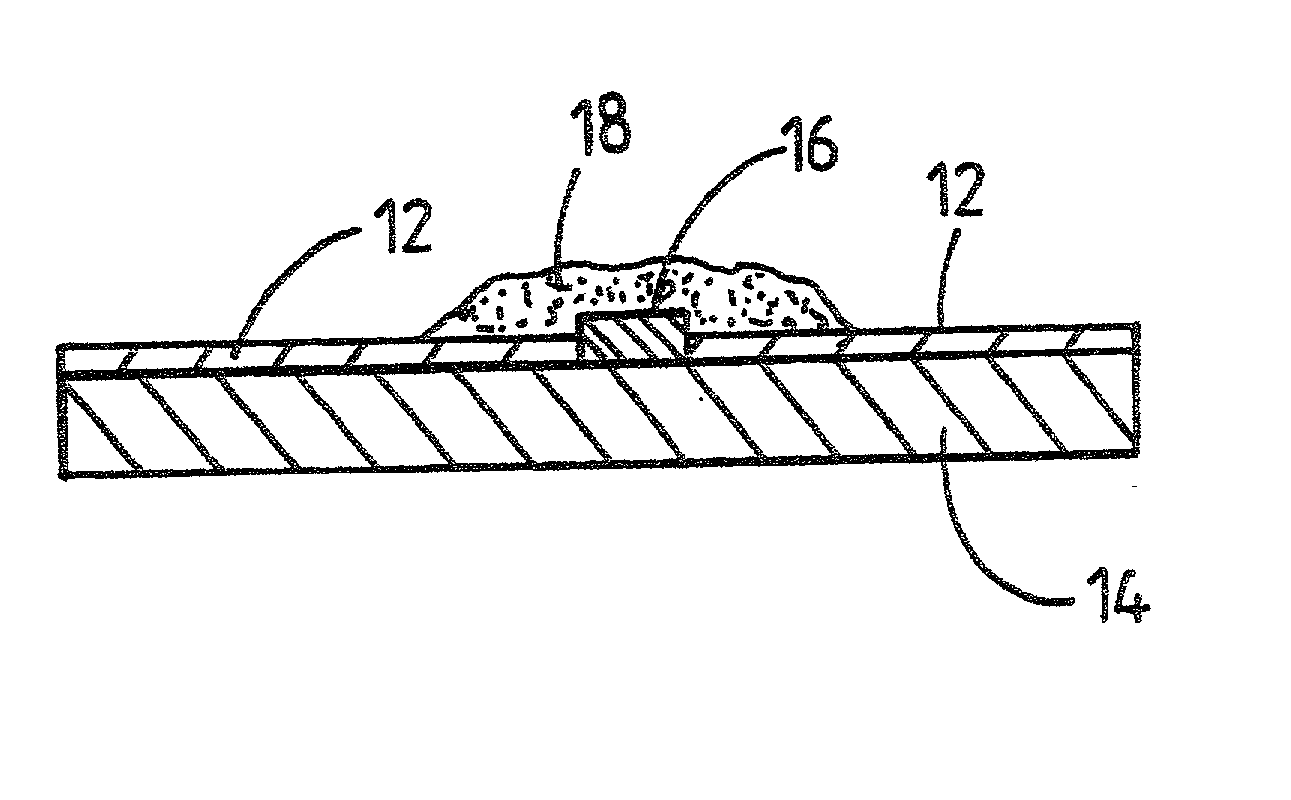

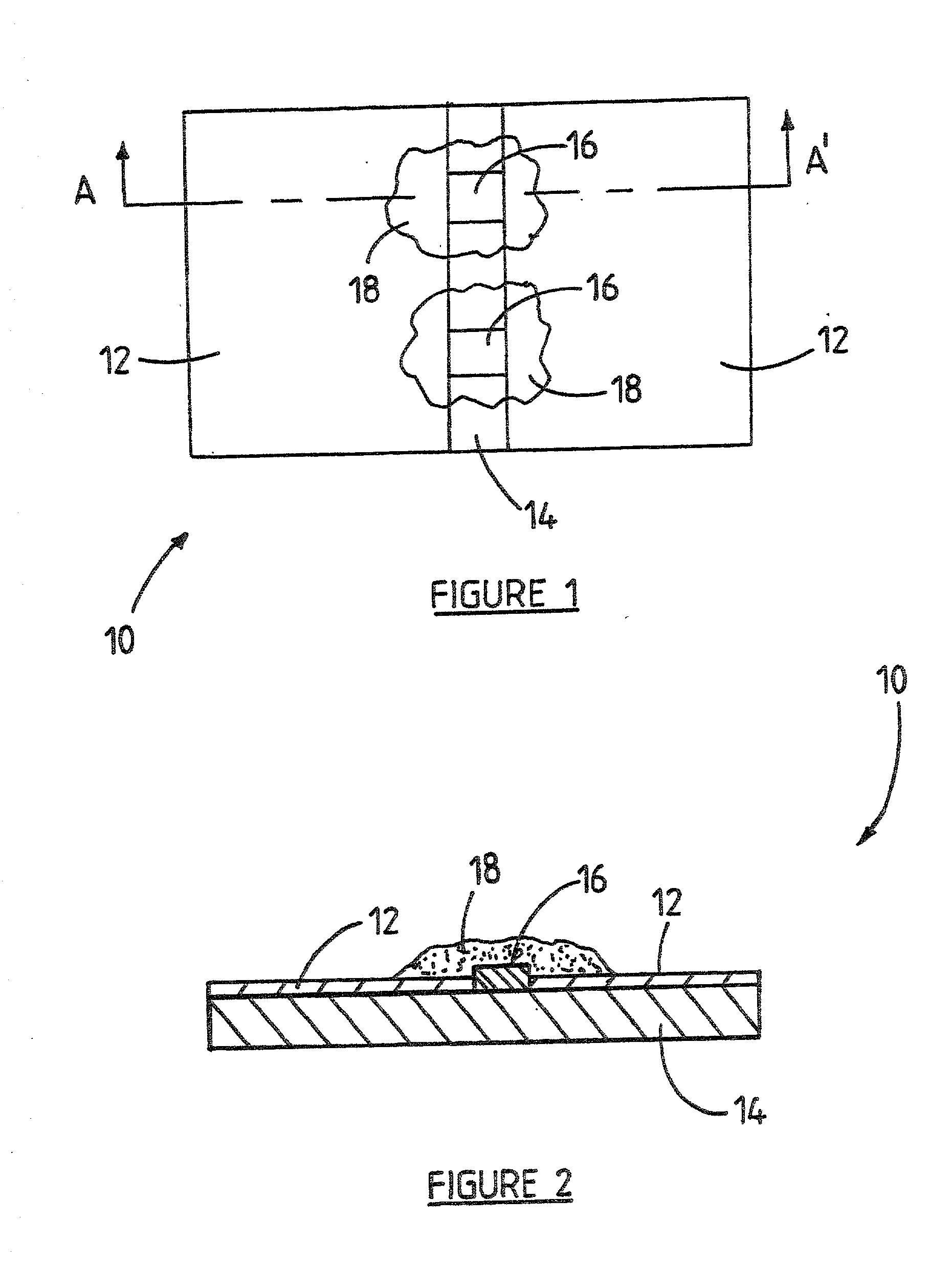

[0030] Referring to FIGS. 1 and 2, according to a first embodiment, the initiating device 10 includes two spaced electrical conductors 12 located on an insulating substrate 14; and two separate resistive means in the form of thick film resistive bridges 16 extending between the electrical conductors 12, for releasing energy upon application of an electrical current to the resistive bridges 16.

[0031] An explosives or pyrotechnic composition, generally designated by reference numeral 18, covers the resistive bridges 16. It will be appreciated that the resistive means need not necessarily be in the form of thick film bridges, but could also be in the form of thin film bridges, wires, dope substances or other resistive substances. There could also be no physical bridge present at all, in which case the resistive path being created by the conductive explosive or pyrotechnic composition itself (see FIGS. 5 and 6).

[0032] The energy requirement of single path resistive initiation devices is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com