Anti-roll bar with link actuator for controlling torsional rigitidy

a technology of torsional rigitidy and anti-roll bar, which is applied in the direction of mechanical equipment, shock absorbers, transportation and packaging, etc., can solve the problems of many parts of the known system, the intermediate portion of the anti-roll bar may be subjected to a torsional force, and the vehicle ride may be affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

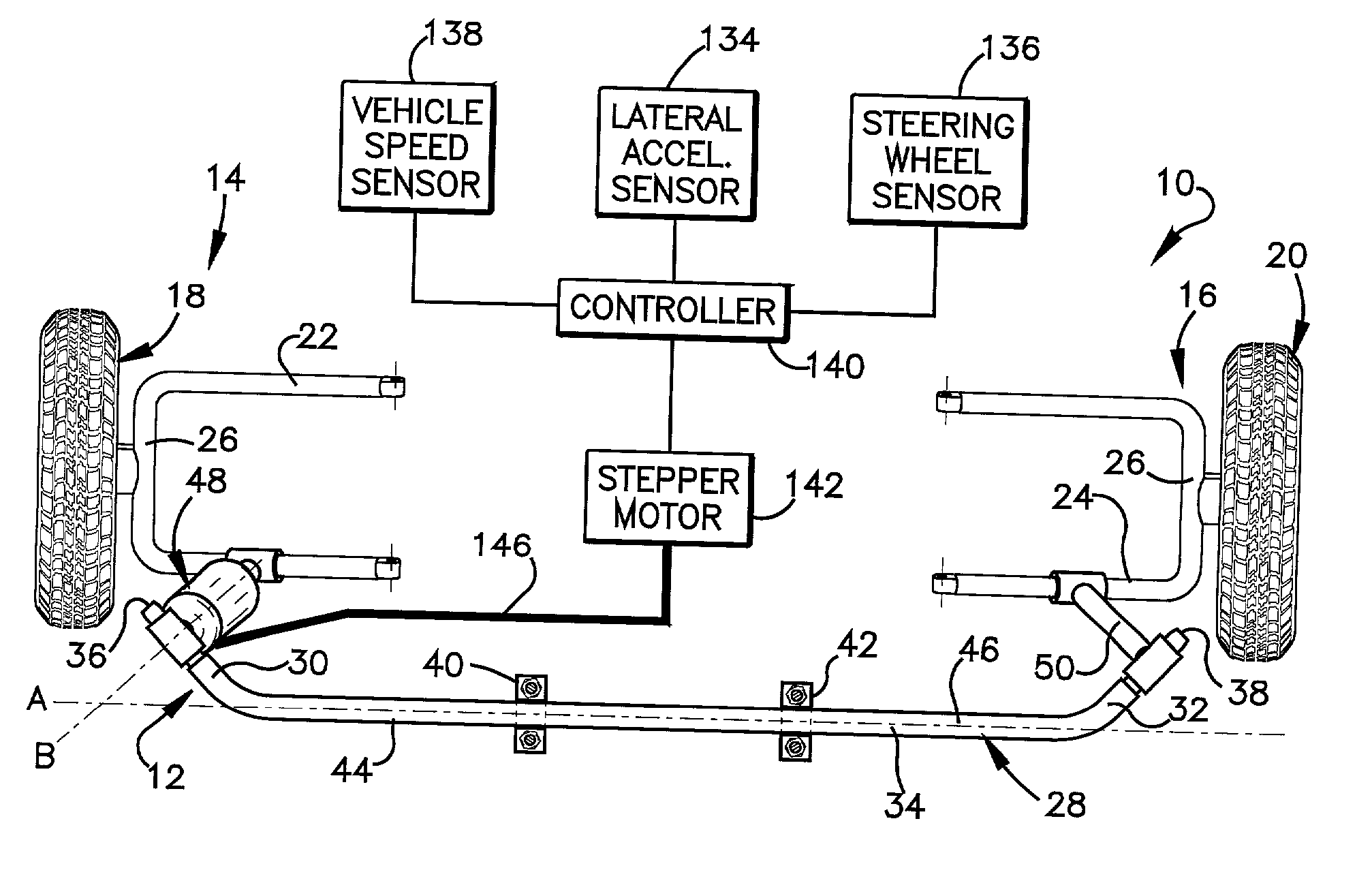

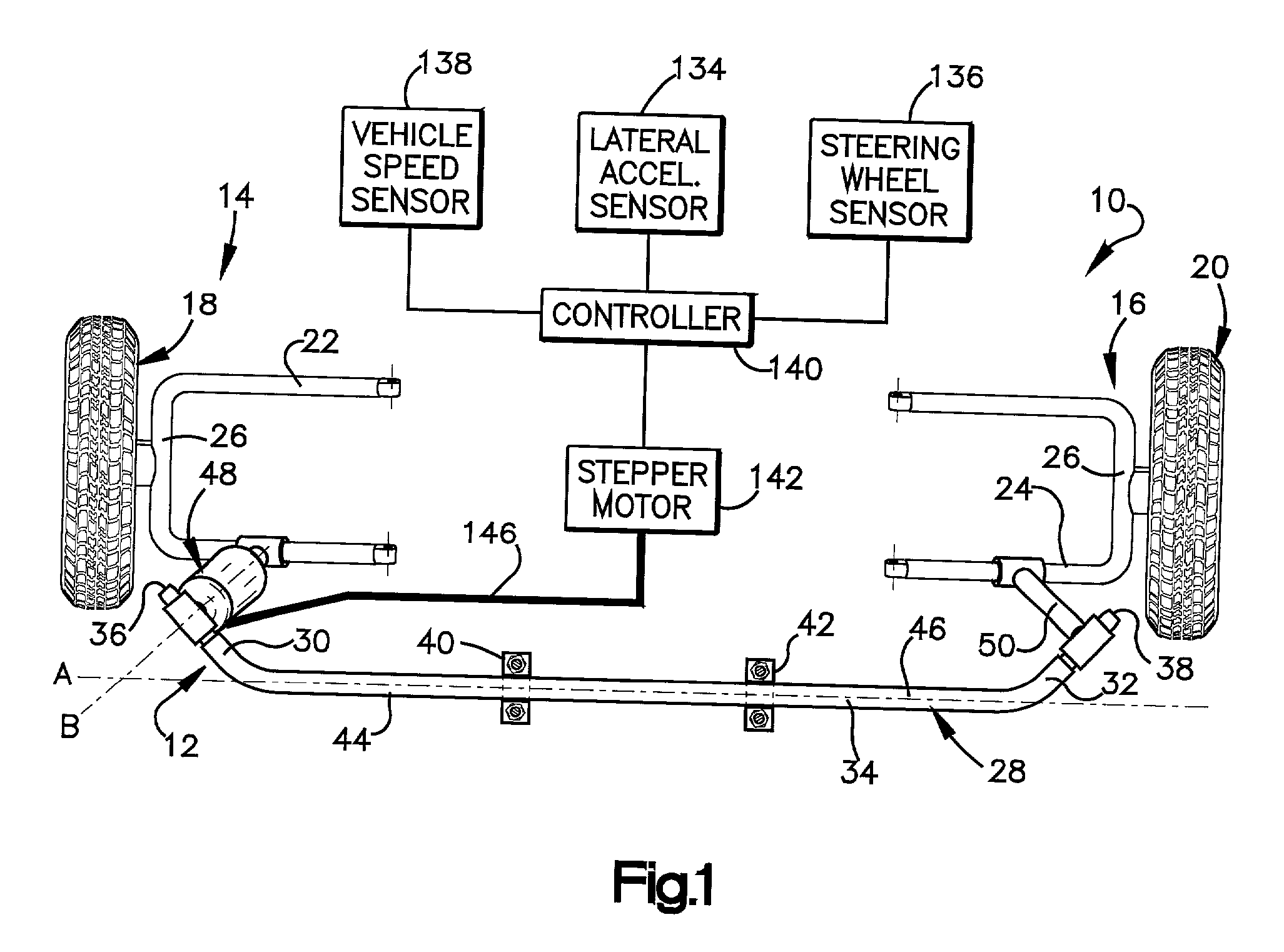

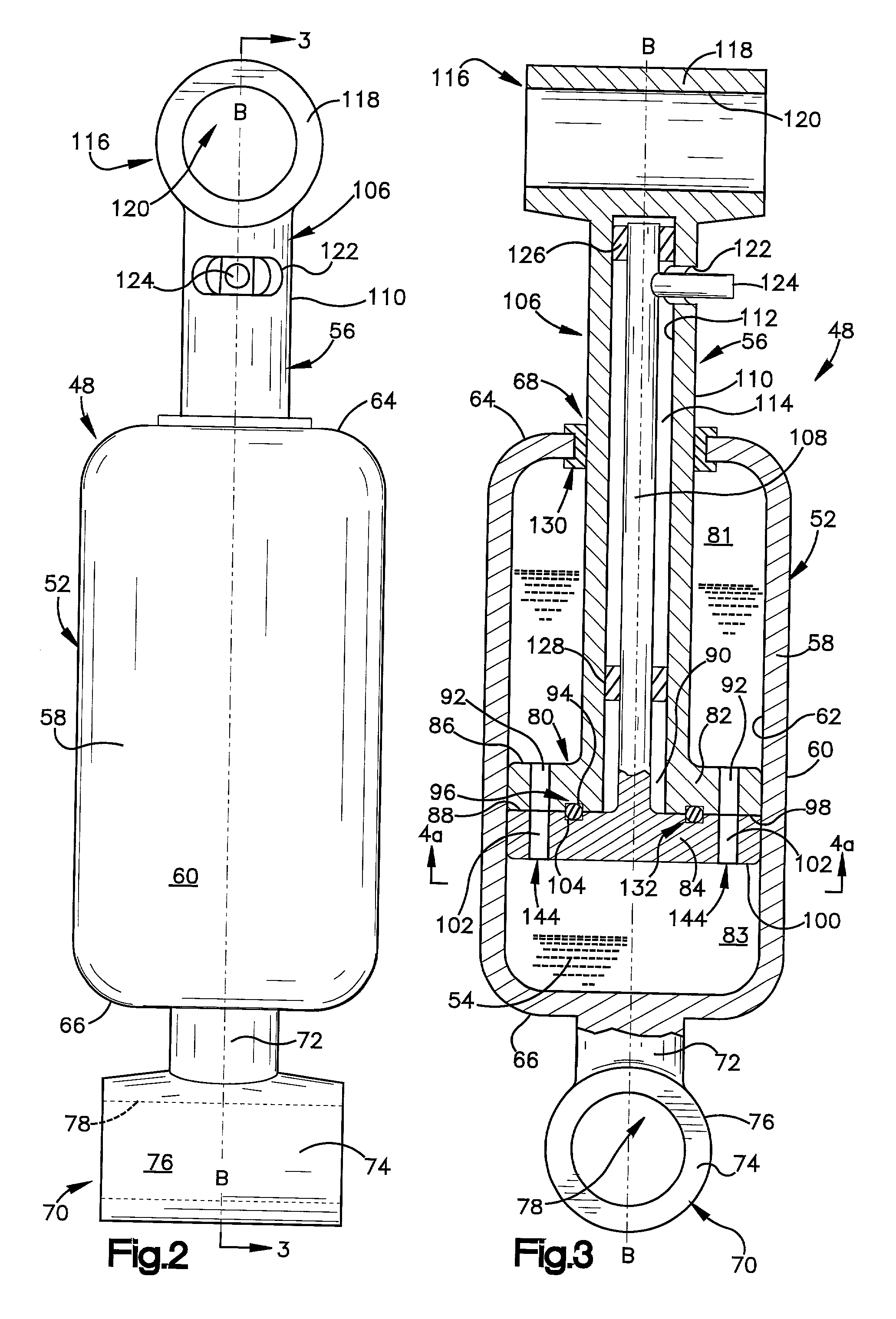

[0015] FIG. 1 schematically illustrates a portion of a vehicle suspension 10 including an apparatus 12 of the present invention.

[0016] The suspension 10 includes a left-hand side 14 and a right-hand side 16. A first steerable wheel 18 is connected to the left-hand side 14 of the suspension 10 and a second steerable wheel 20 is connected to the right-hand side 16 of the suspension 10.

[0017] The left-hand side 14 of the suspension 10 includes a first control arm 22 and the right-hand side 16 of the suspension 10 includes a second control arm 24. Both the first and second control arms 22 and 24 are U-shaped. Steerable wheel 18 connects with a closed portion 26 of the U-shape of control arm 22. Steerable wheel 20 connects with a closed portion 27 of the U-shape of control arm 24.

[0018] The apparatus 12 of the present invention includes an anti-roll bar 28. The anti-roll bar 28 includes opposite first and second end portions 30 and 32, respectively. An intermediate portion 34 is interpos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com