Chromatography device

a chromatography device and chromatography column technology, applied in the direction of filtration separation, separation processes, instruments, etc., can solve the problems of difficult tooling for operators, limited access to the end piece or mounting bolts, and undesirable disassembly of columns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

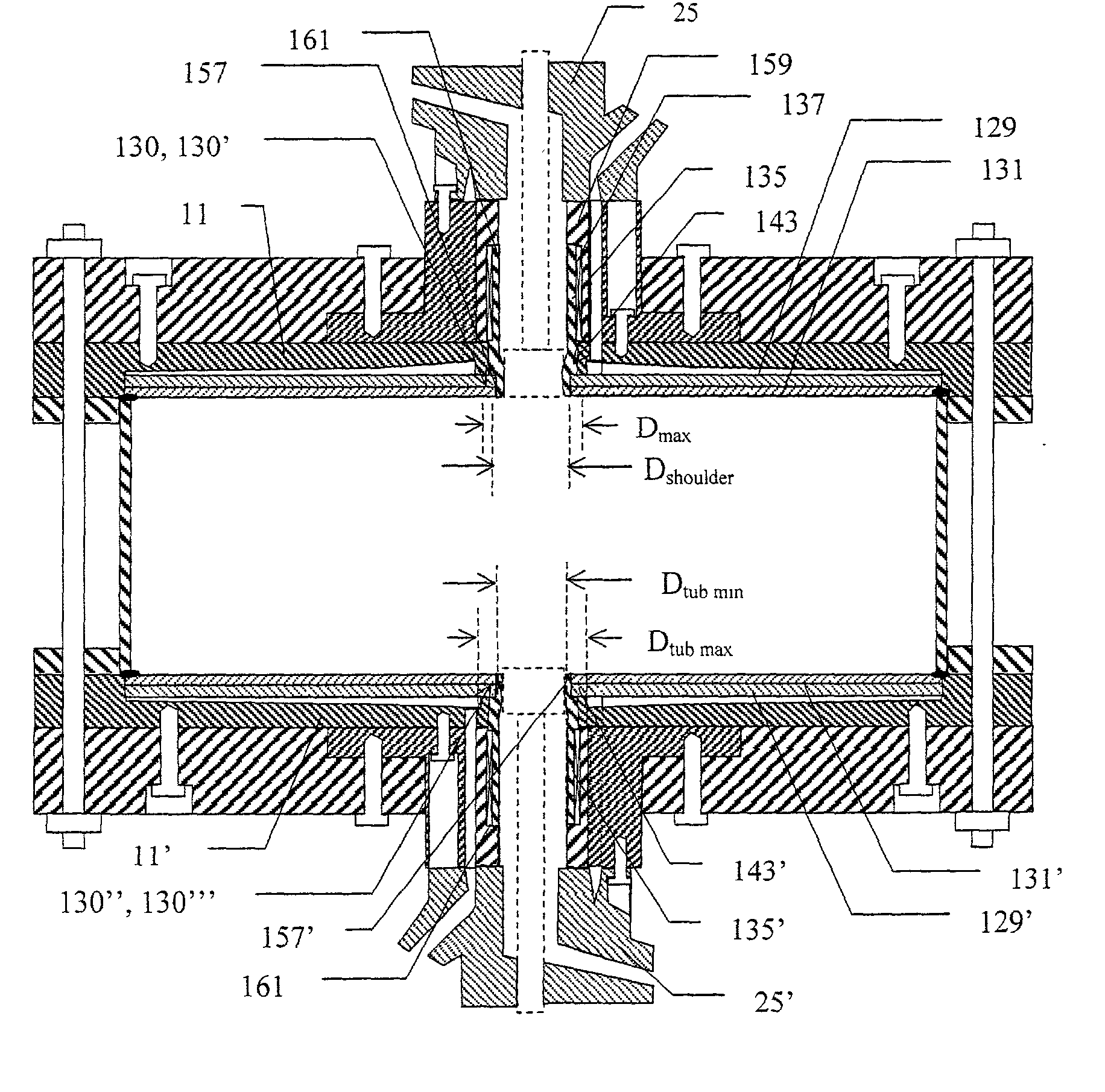

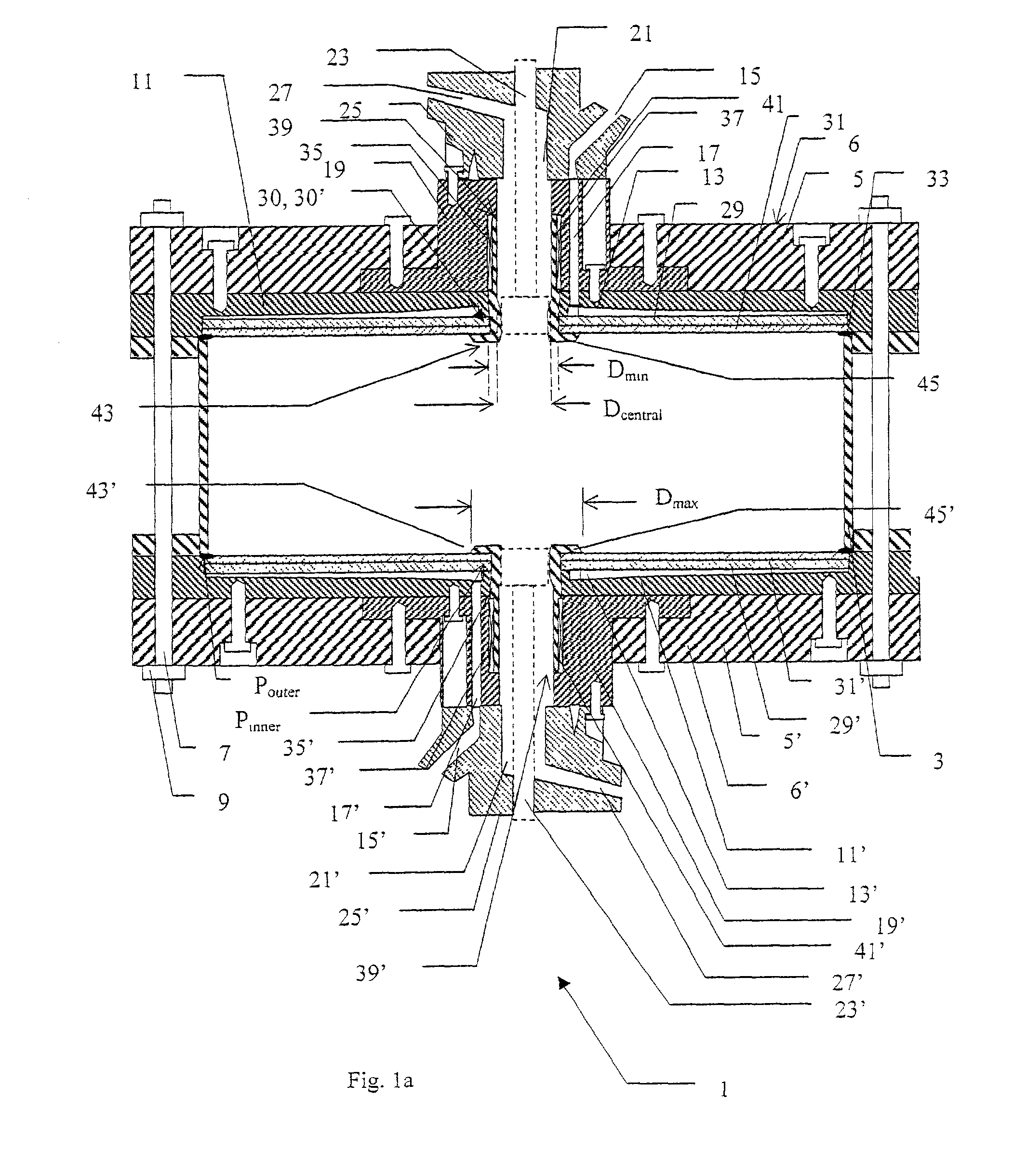

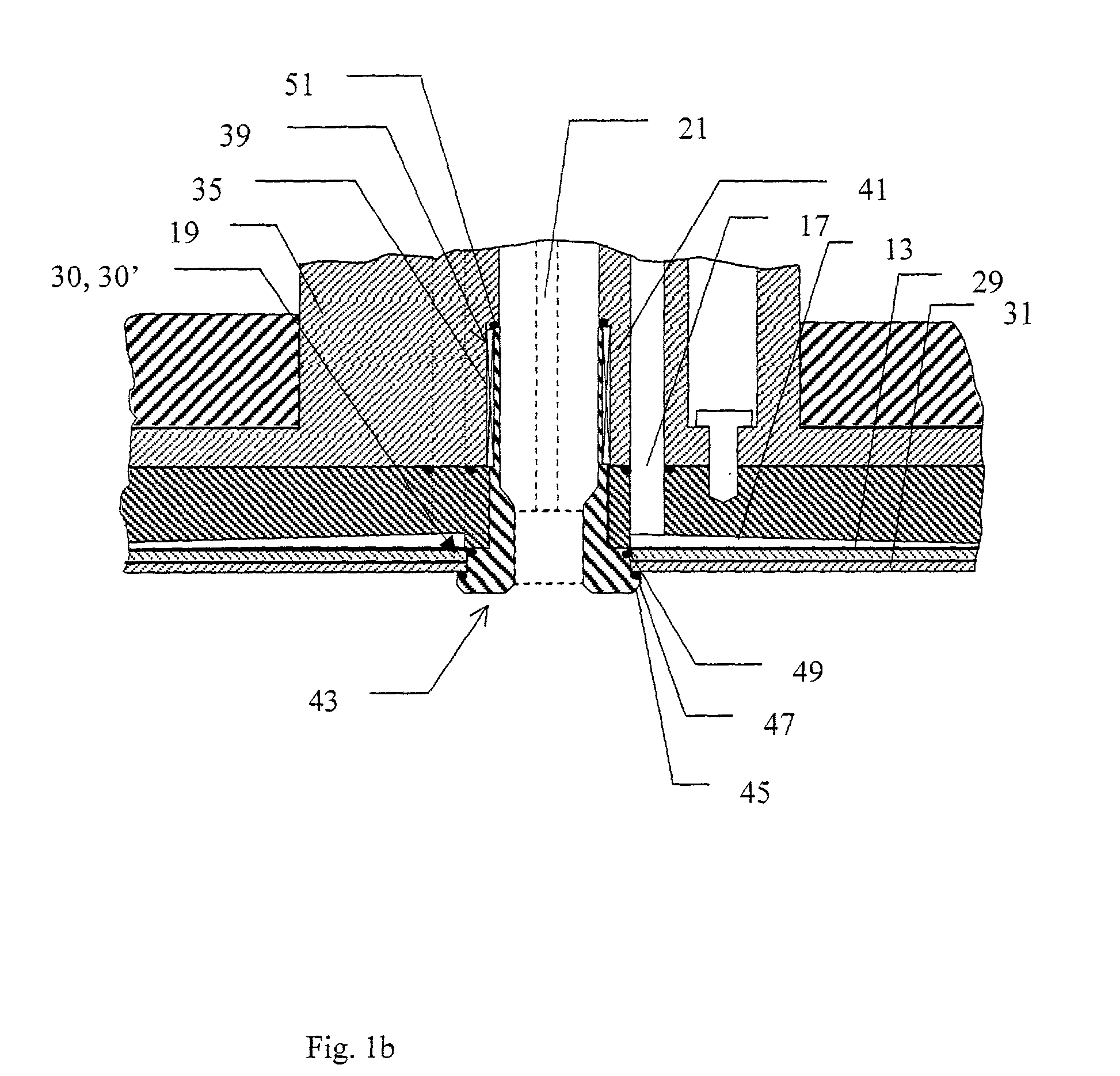

[0016] FIG. 1 shows schematically an embodiment of a prior art chromatography column 1. In this example the two ends of the column are substantially identical and either end can be used as the inlet end while the other end is used as the outlet end. For the sake of convenience and clarity of description, it will be assumed that the upper end of the column is the inlet end while the bottom end is the outlet end. Column 1 has a cylindrical wall 3 that has an end plate 5, 5' mounted on it at, respectively, the upper end 6 and the lower end 6' and these are held in place by external longitudinal threaded tie bars 7 with tensioning nuts 9. The space bounded by the wall 3 and end plates 5, 5' is intended to contain a bed medium (not shown). Each end plate 5, 5' supports a distributor cell 11, 11' on its side facing into the column 1. Each distributor cell 11, 11' has mobile phase distributing means, for example radially extending ribs 13, 13', for evenly distributing the mobile phase over...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com