Paint ball reservoir with stiffener insert

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following discussion describes in detail one embodiment of the invention and several variations of that embodiment. This discussion should not be construed, however, as limiting the invention to those particular embodiments. Practitioners skilled in the art will recognize numerous other embodiments as well.

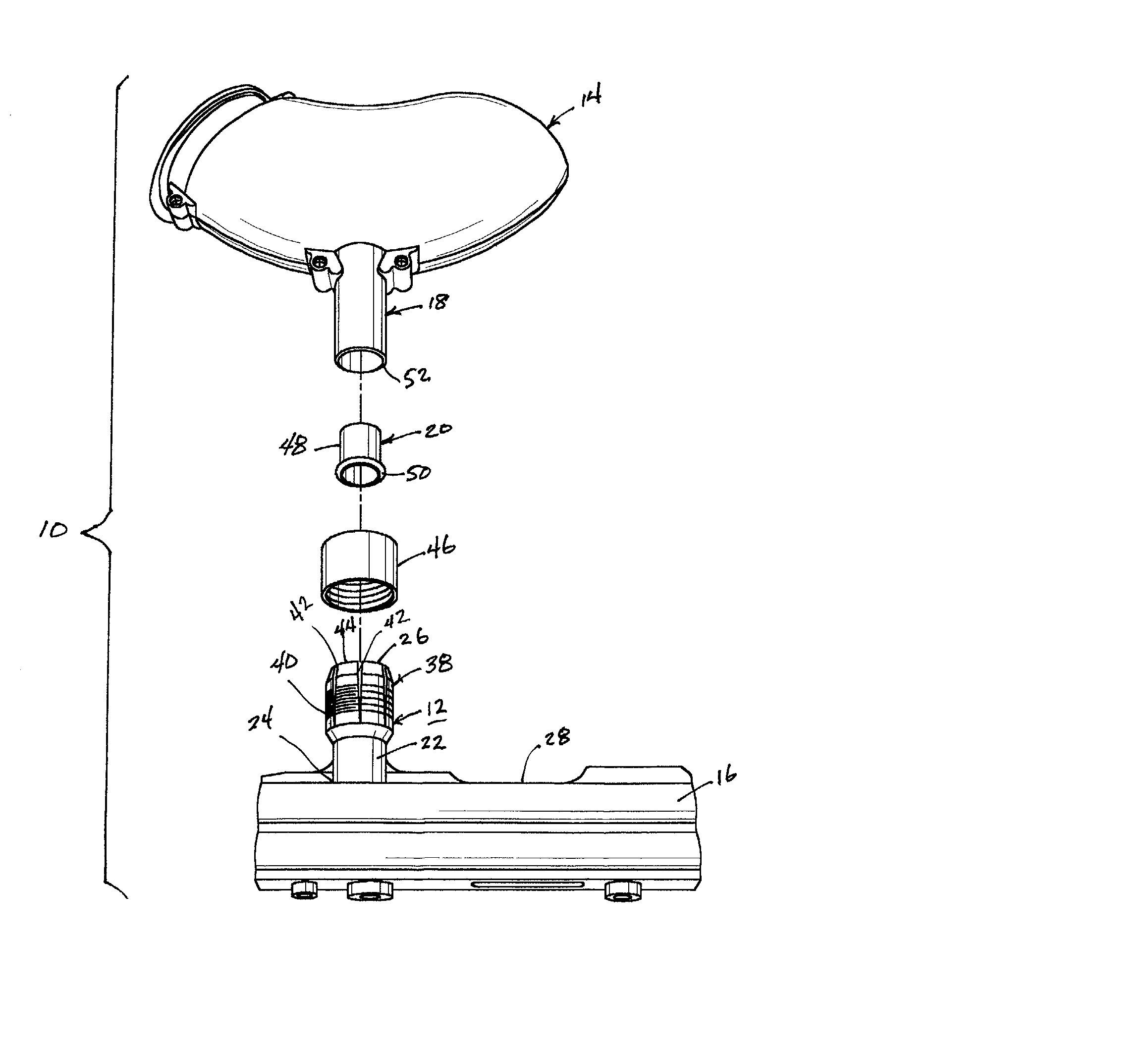

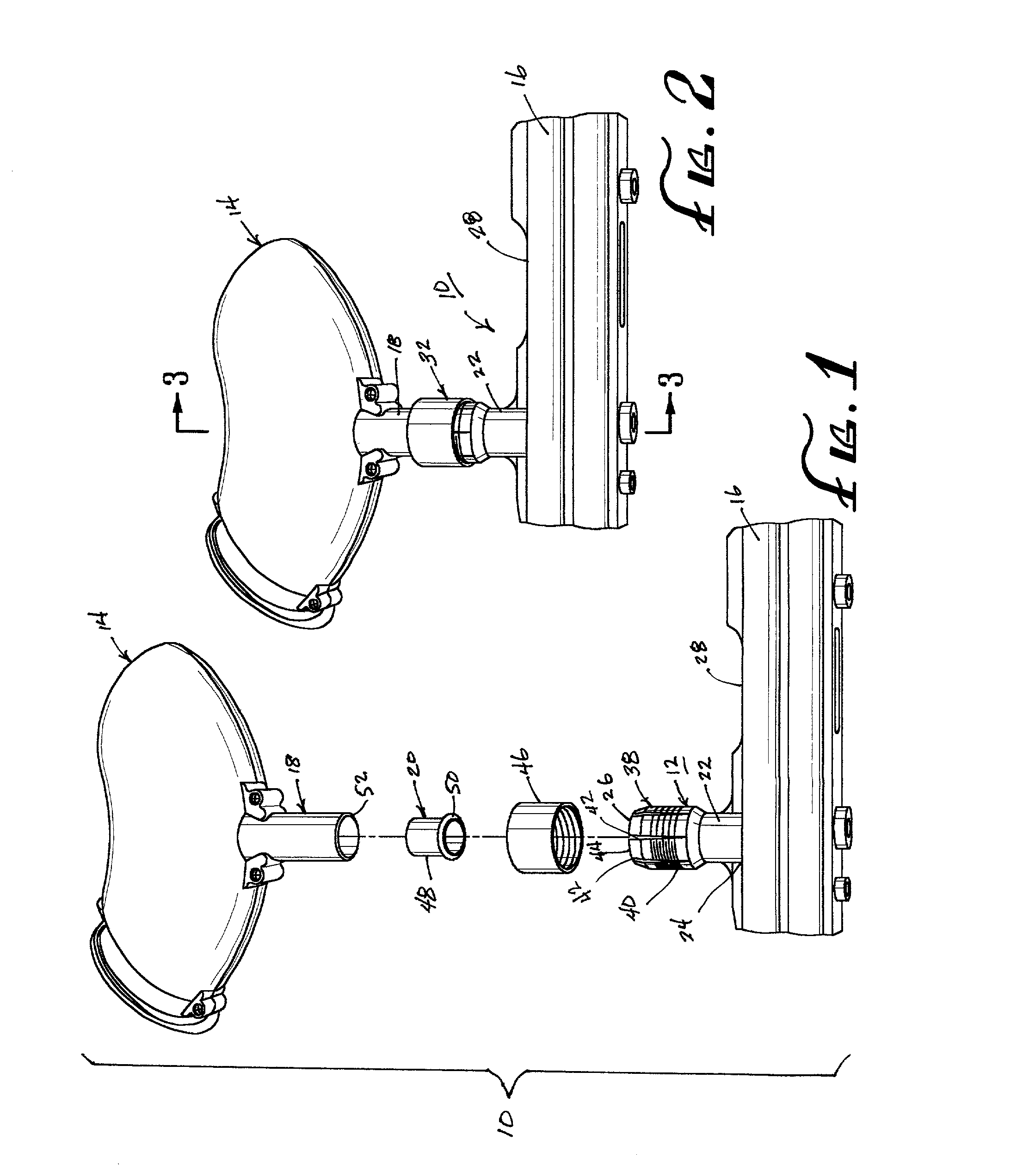

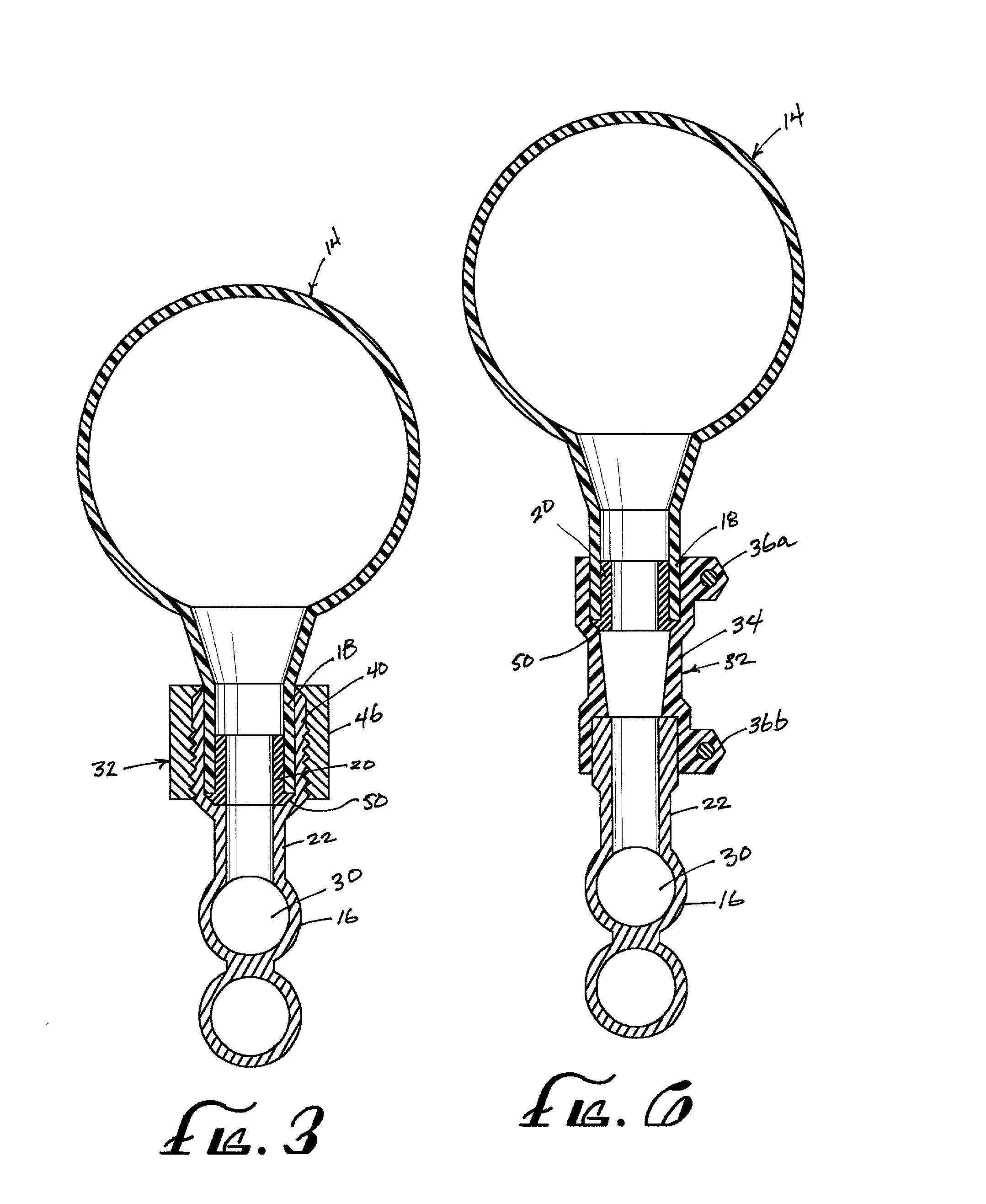

[0018] The invention is a paint ball gun 10. The paint ball gun 10 comprises a reservoir connector 12 for connecting a paint ball reservoir 14 to the paint ball gun barrel 16. The paint ball reservoir 14 comprises a downwardly directed reservoir nipple 18. The reservoir nipple 18 has an outside diameter between about 3 / 4 inches and about 2 inches, most typically between about 7 / 8 inches and about 11 / 8 inches. In the invention, a stiffener insert 20 is disposed within the reservoir nipple 18.

[0019] The reservoir connector 12 comprises a connector nipple 22 having a lower end 24 and an upper end 26. The lower end 24 is adapted for attachment to the upper portion 28 of a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com