Water weighted tarp

a self-weighting, tarpaulin technology, applied in the direction of building components, transportation and packaging, building insulation, etc., can solve the problems of prone to tearing the tarpaulin, jeopardizing the entire tarpaulin, and objects that are not always handy, so as to achieve continuous and uniform water weighting, the effect of not being able to blow away

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

of the Figures

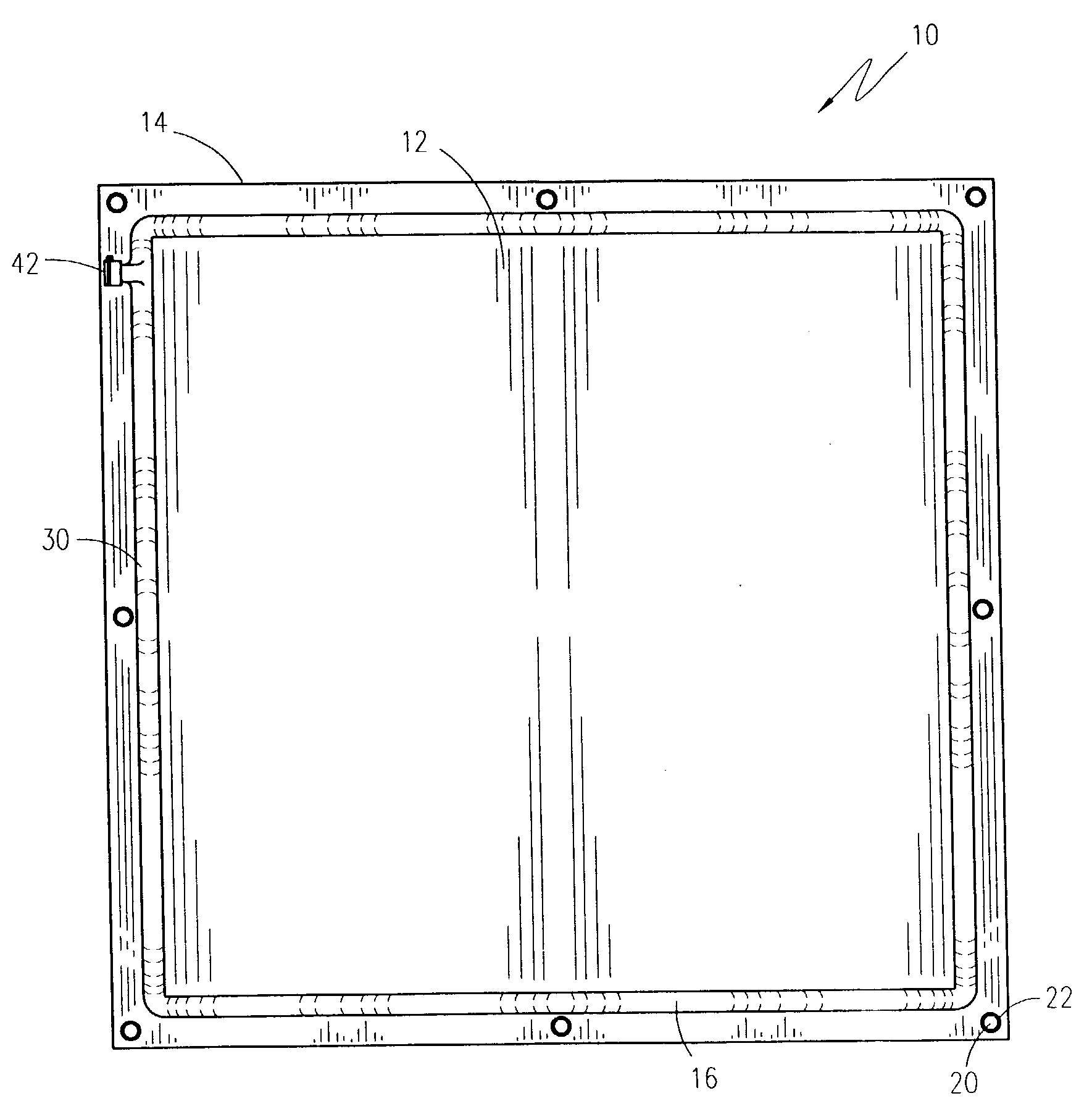

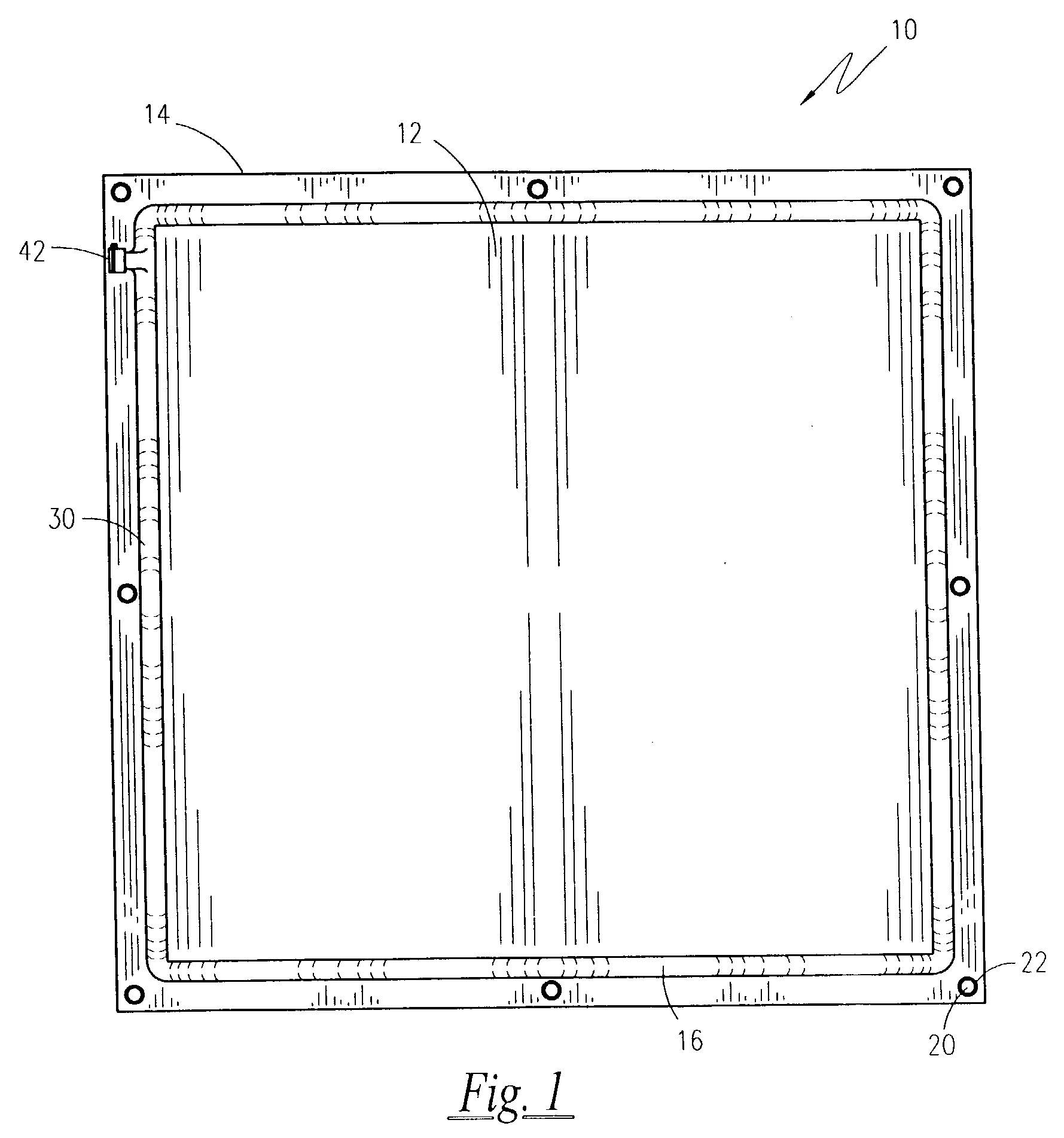

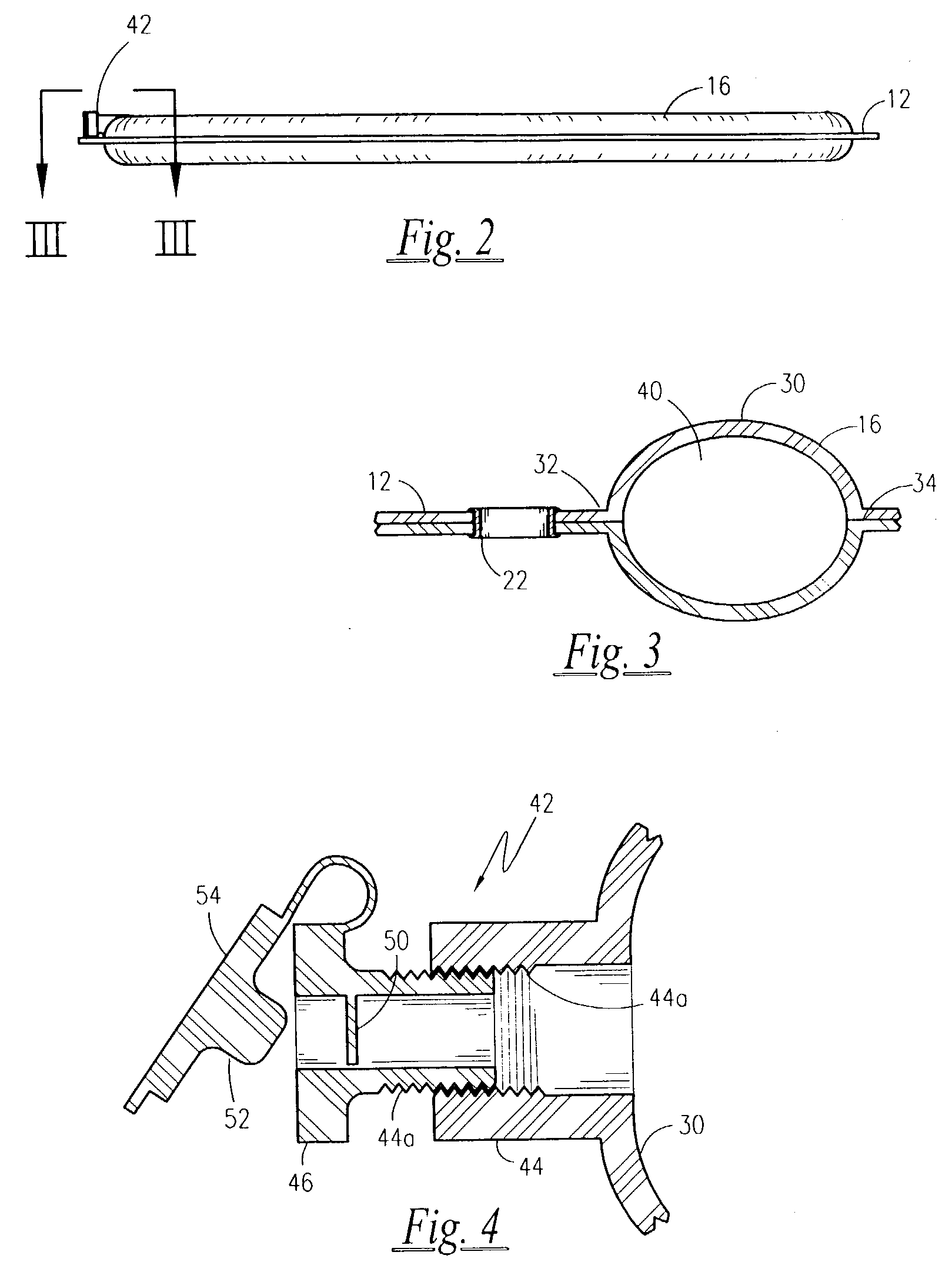

[0035] Referring now to FIG. 1-2, a weighted water tarp apparatus 10 is shown, according to the present invention, having a generally flat tarp planar surface 12 anticipated as being of an otherwise conventional material and construction as tarps currently available. Shown here as rectangular in shape, it is envisioned that any geometry could also incorporate the teachings of the present invention. The tarp planar surface 12 is bounded by a peripheral hem 14, and is circumscribed out its outer perimeter by a perimeter tube 16. The peripheral hem 14 is shown forming a plurality of tie-down holes 20, each aligned with conventional metal grommets 22 for added strength and resistance to tearing. The peripheral tube 16 is shown in greater detail in conjunction with FIG. 3, and has a seamless upper tube sidewall 30 terminated at each side in an attachment flange 32. A lower sidewall 34 is affixed to the attachment flanges 32 in a water-tight, sealed manner. Similarly, the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com