Safety device for firearms with a firing pin lock

a safety device and firearm technology, applied in the direction of safety arrangement, weapons, weapons, etc., can solve the problems of inability to fire shots, inability to release safety wing unintentionally from the secure position, and inability to exclude inadvertent release of safety during normal use of weapons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention is being described further, by example of the widespread firing pin lock type "Dakota". The arresting of the safety shaft here is easily achieved. Notably, this invention can be implemented or other locks of similar design, since a particular advantage of the present invention is that it can be fitted to already existing locks.

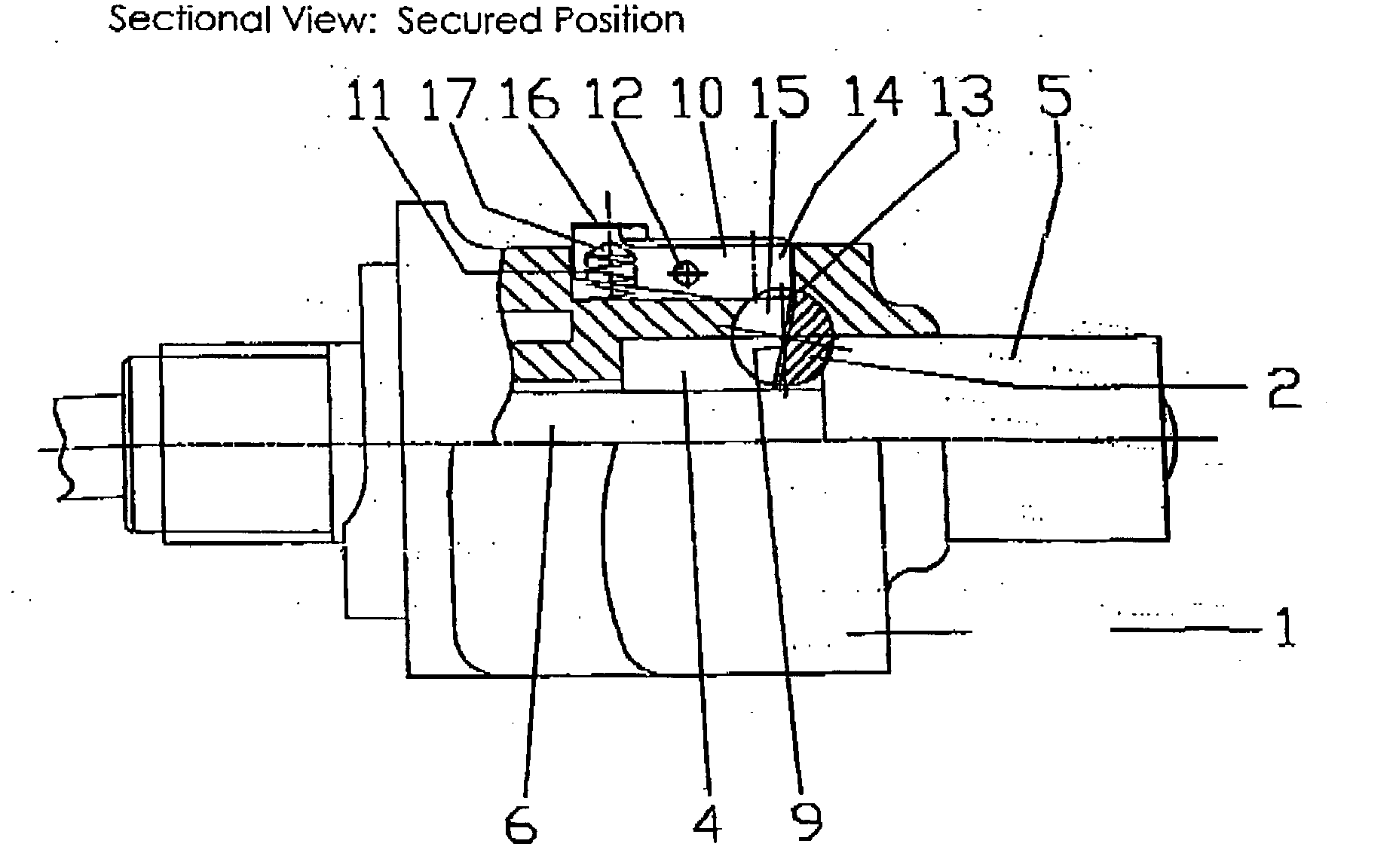

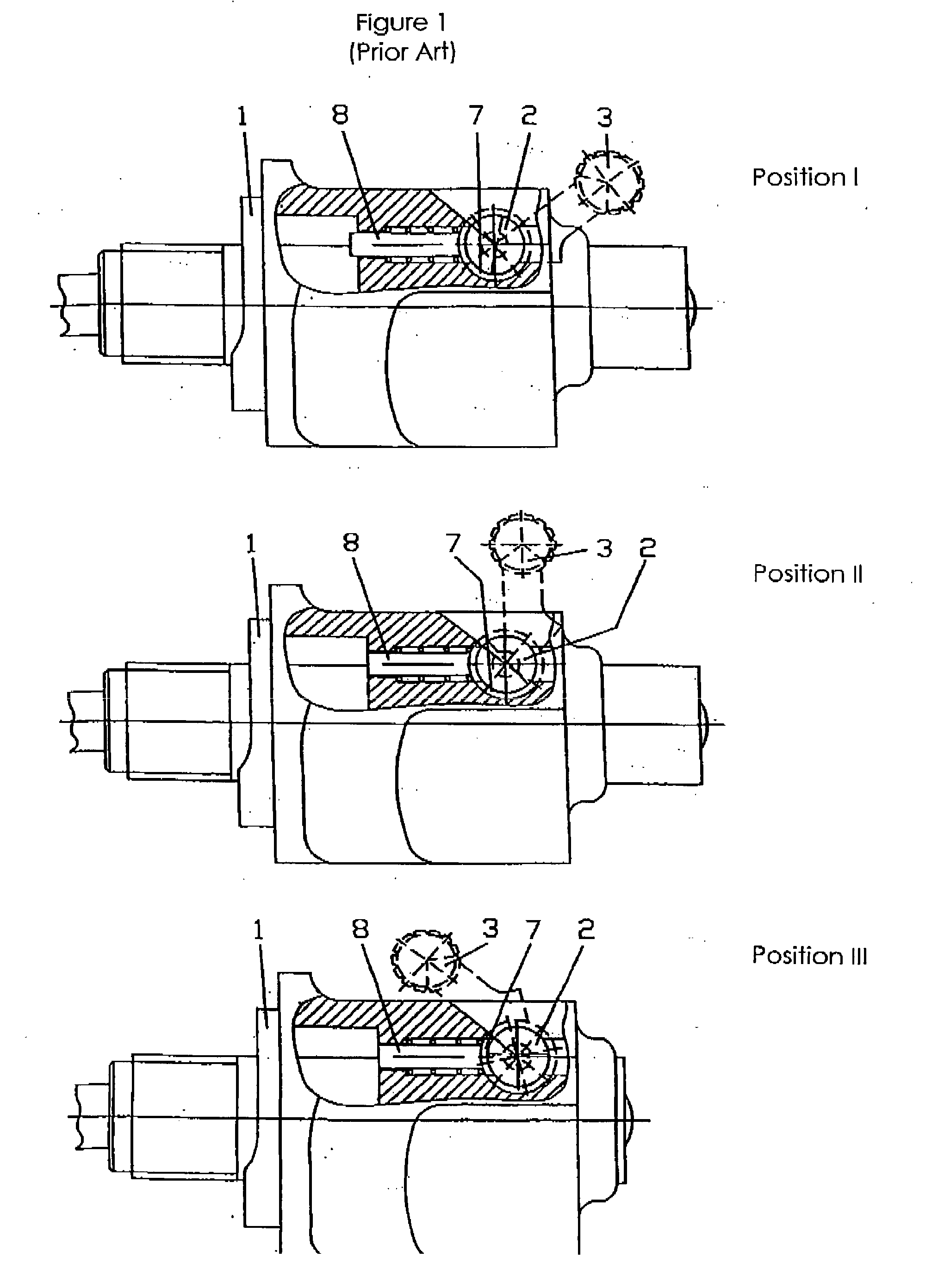

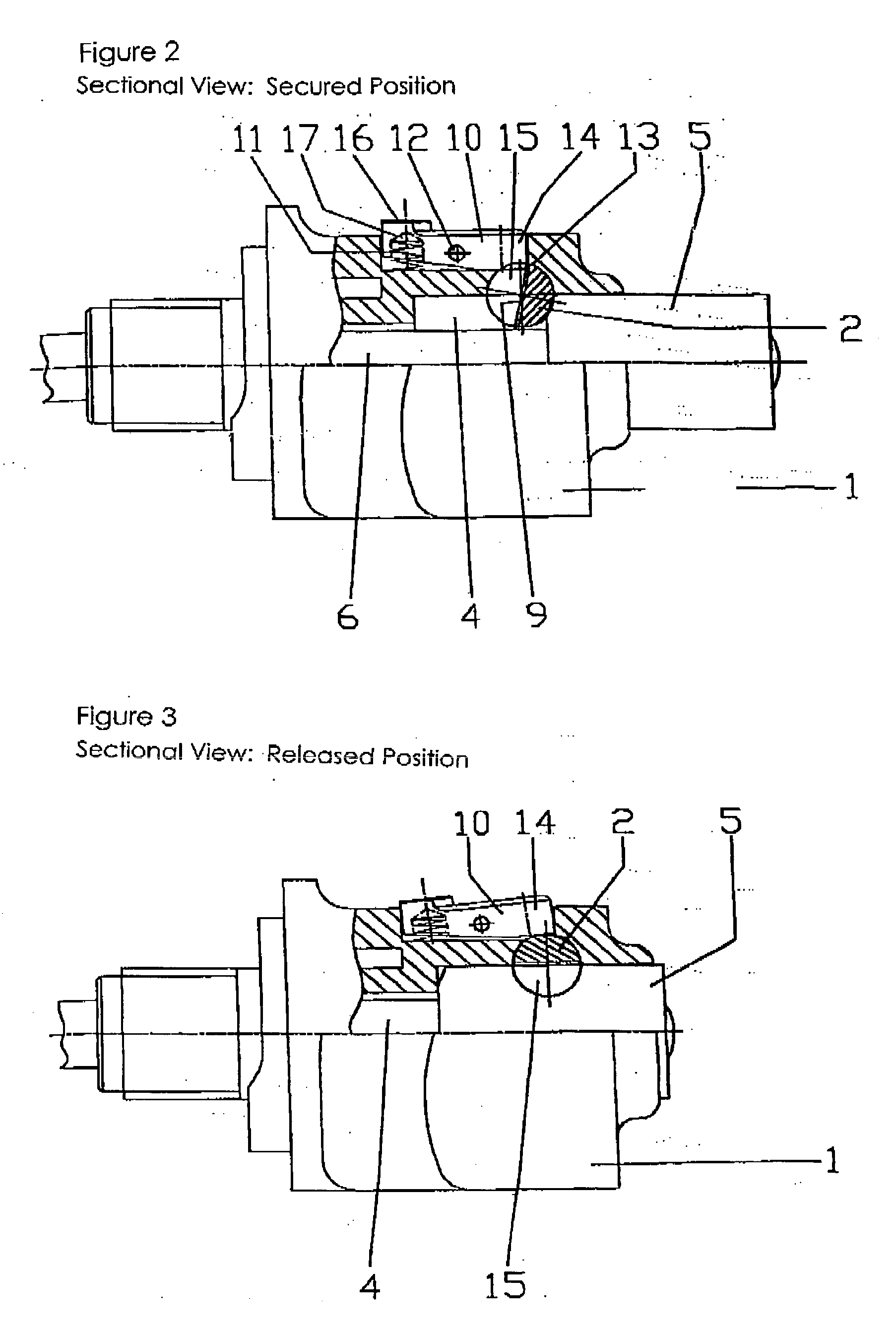

[0017] The firing pin lock 1 in FIG. 1 in top view is provided with a safety shaft 2. The safety shaft 2 is situated in the lock 1 and is turned by means of the safety wing 3 affixed to it. In the shown position I of the safety wing 3 the weapon is completely secured. The safety shaft 2 is swiveled into the firing pin bore 4 (FIG. 2) and abuts to the nut / mother of the firing pin 5. Thereby the firing pin 6 is blocked. At the same time the pin 8 is pushed forward through the cam area 7 into a dead end bore existing close by the socket, which is not shown in detail, and the lock 1 is thereby secured against turning. The position of the pin 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com