Fluidic MEMS device

a microelectromechanical and fluid technology, applied in microstructural devices, microstructure technology, printing, etc., can solve the problems of fluid leakage and/or fracture of packaging materials, incompressible fluids, and low compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

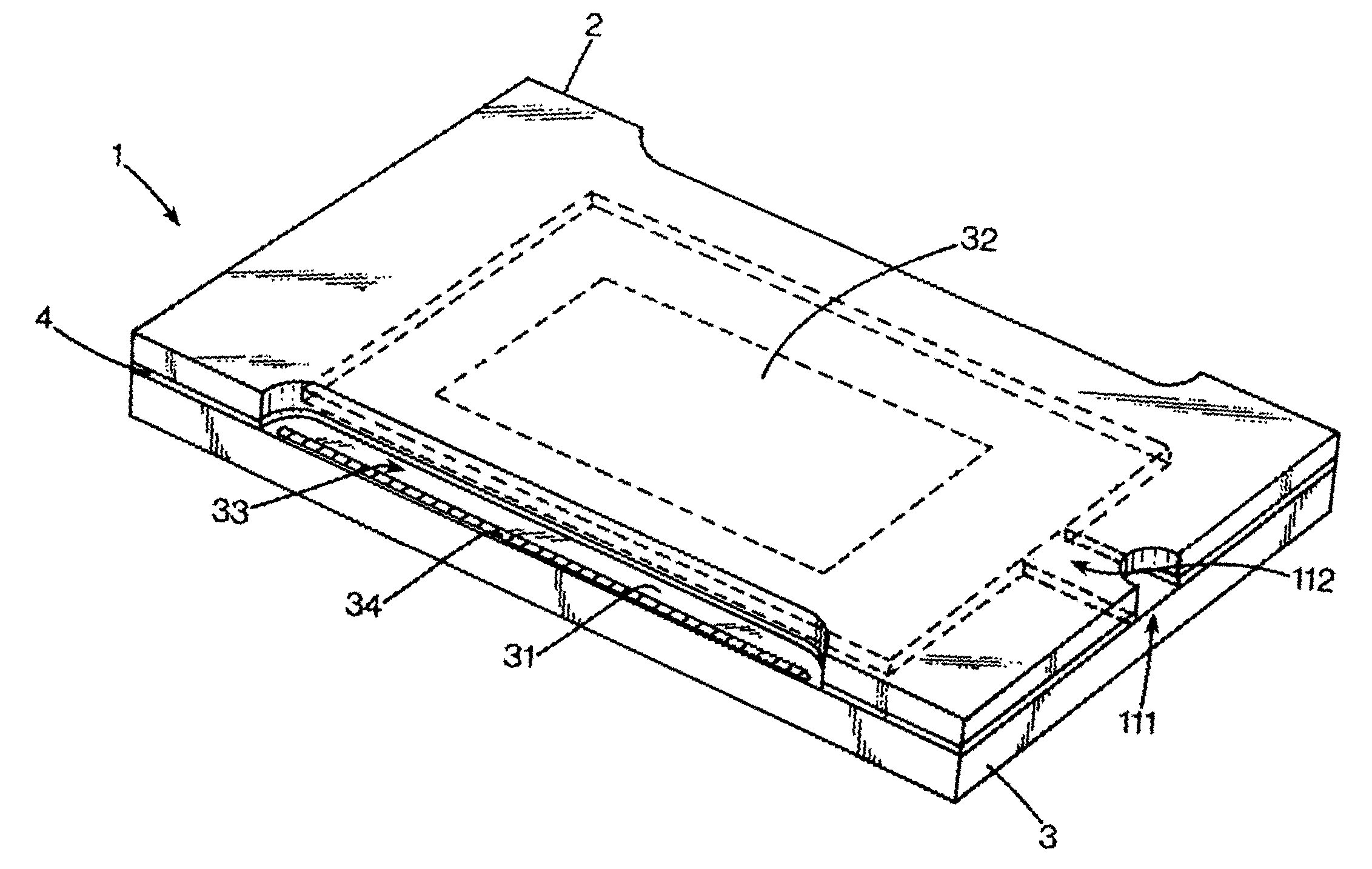

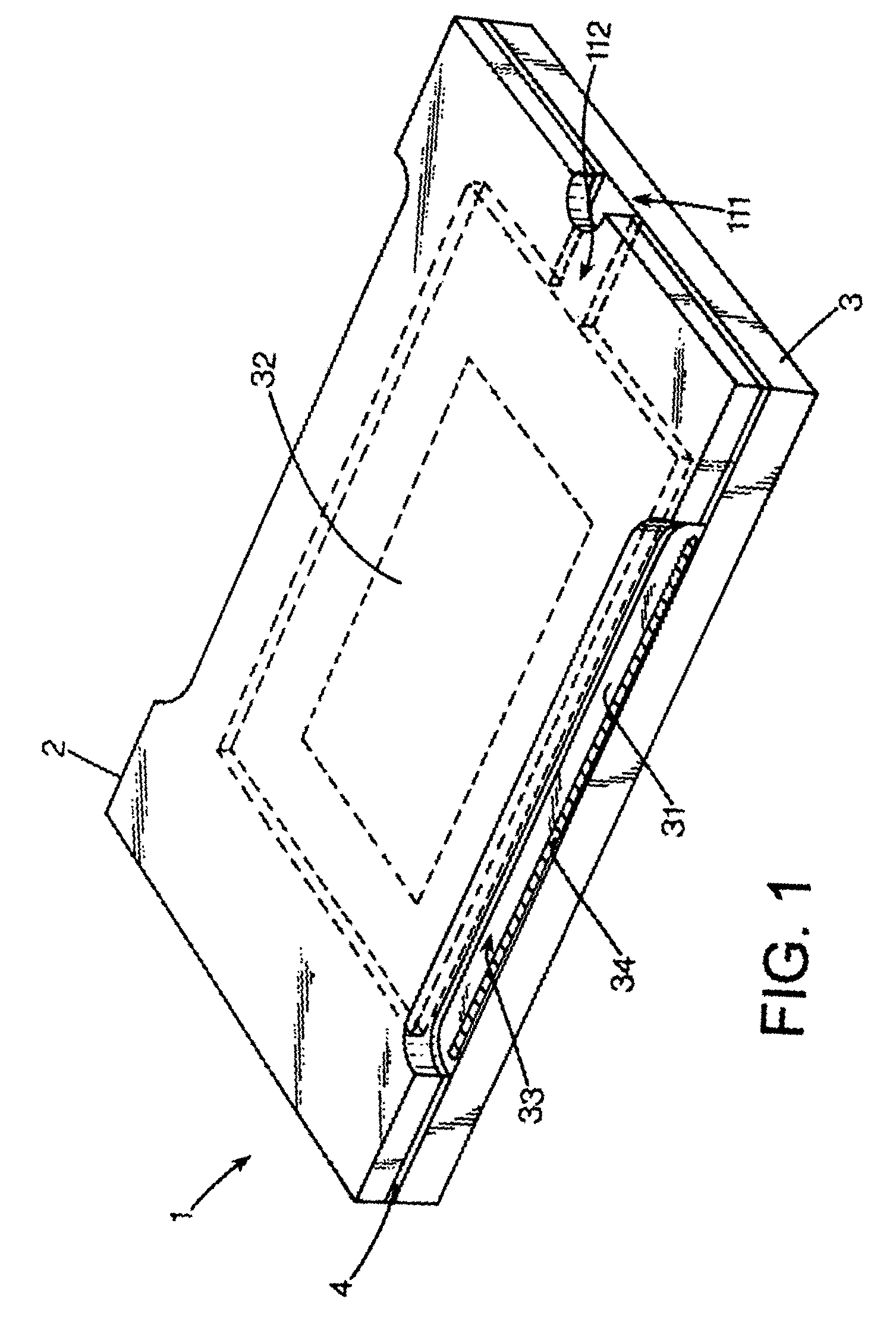

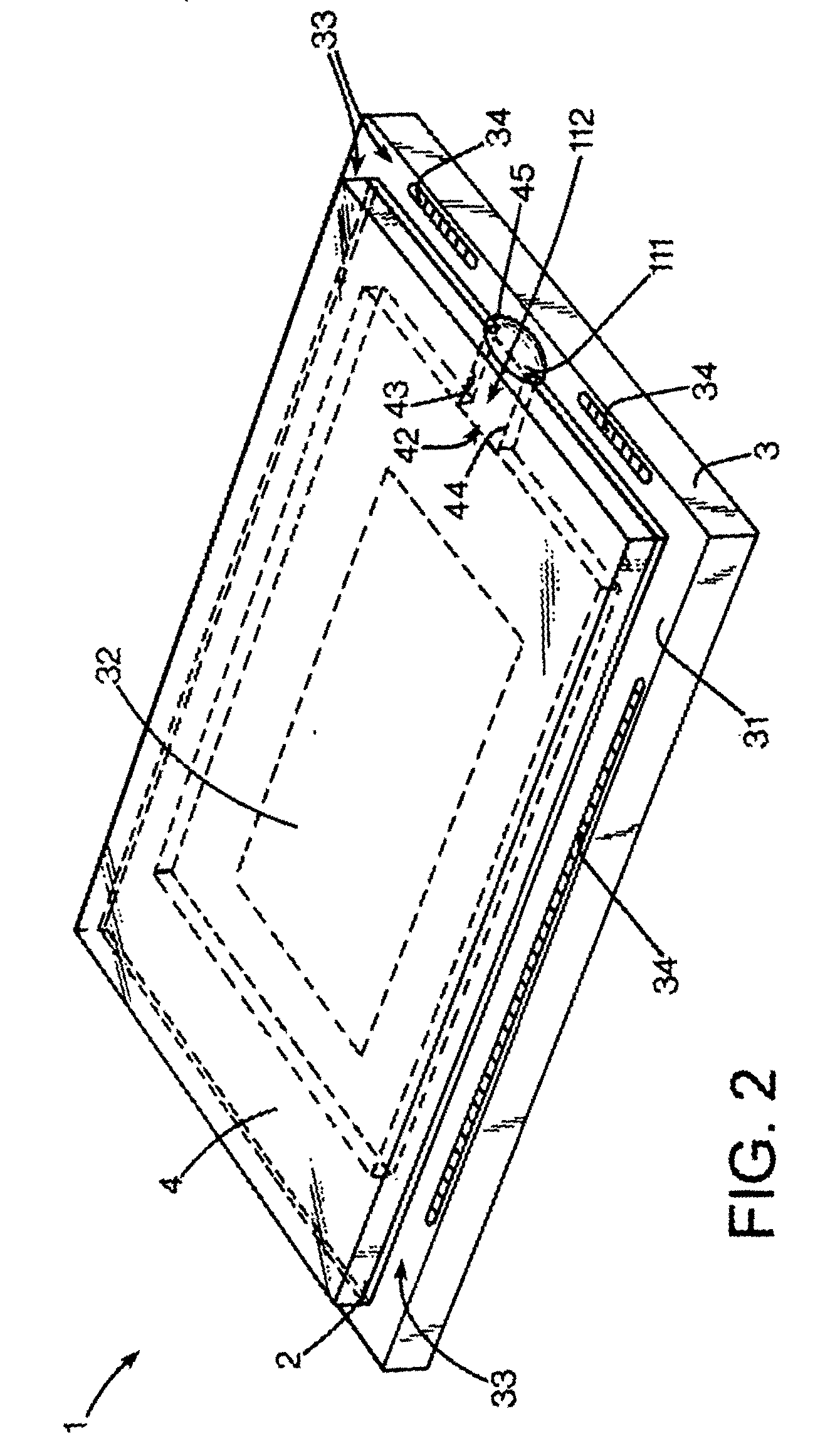

[0014] In the following detailed description and in the several figures of the drawing, like elements are identified with like reference numerals.

[0015]FIGS. 1 through 4 illustrate exemplary embodiments of MEMS package assemblies suitable for use as fluidic MEMS devices. A MEMS assembly or package 1 includes a cover plate 2, a substrate 3 and a bond ring 4. A primary face 21 (FIG. 3) of the cover plate 2 is attached to a primary surface 31 of the substrate by a bond ring 4. The cover plate 2 may be an optical window or aperture and may comprise silicon, glass, plastic, metal or metal alloys, such as Kovar (TM), or other suitable material. The substrate 3 may be a silicon substrate and may have a MEMS structure 32 fabricated on the primary surface 31. The bond ring 4 may be an inorganic bond ring. The cover plate may be smaller than the substrate and may define exposed portions 33 on the substrate which are not covered by the cover plate. Electrical bonding pads 34 for making electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com