Cable ties having innate connection compatibility with mounting plates

a technology of innate connection and mounting plate, applied in the field of cable ties, can solve the problems of inability to group with the pre-existing closely-mounted mounting plate, and difficulty is not resolvabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

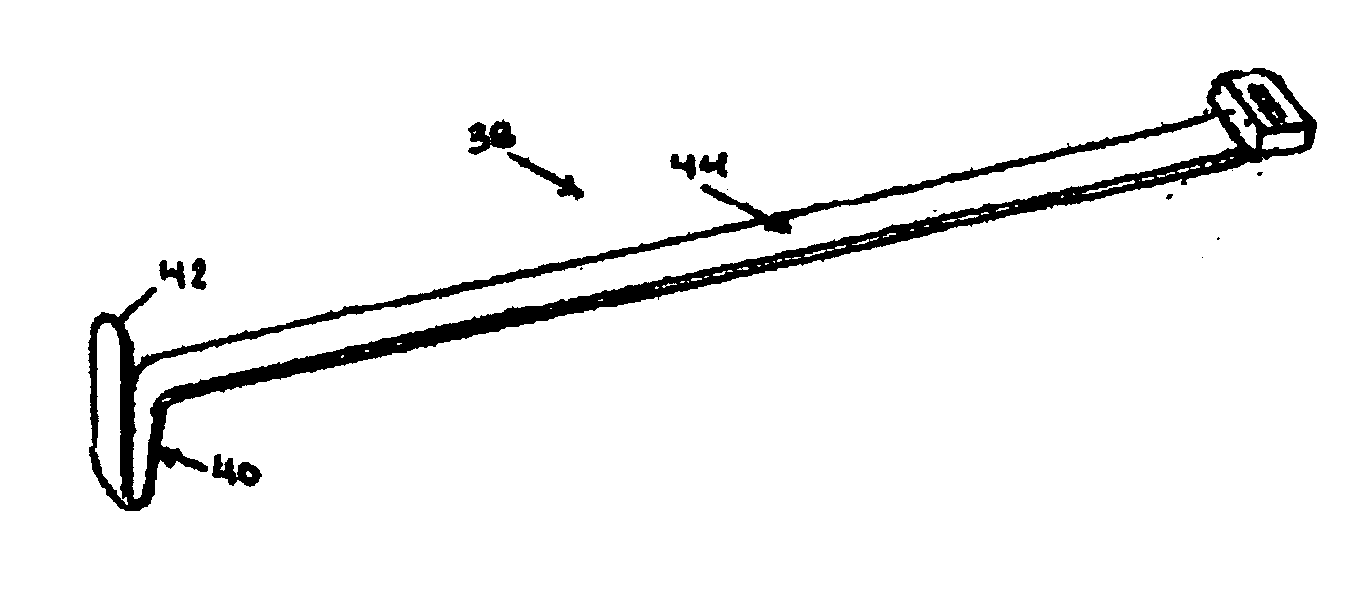

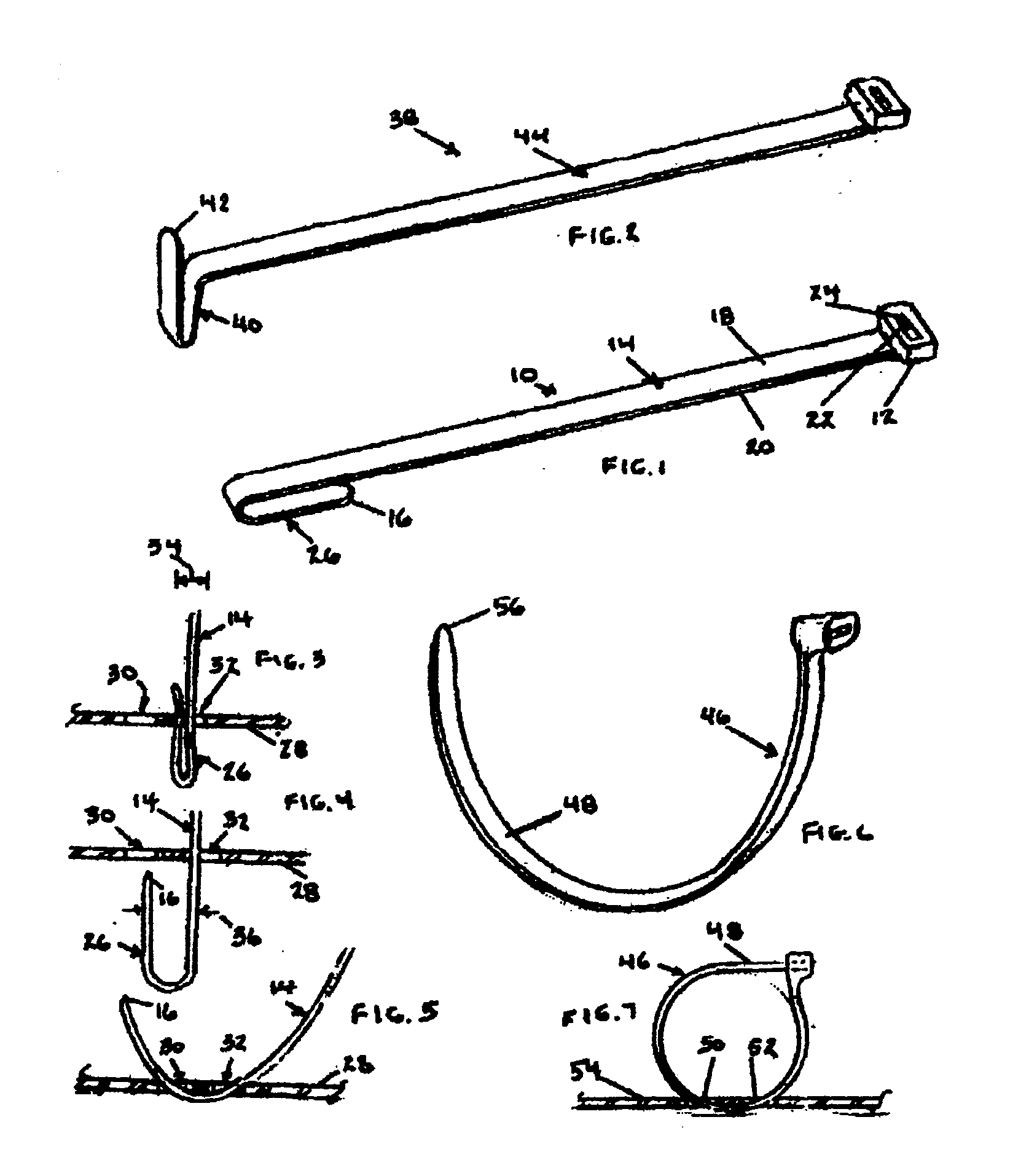

[0016] Referring to FIG. 1, cable tie 10 includes a head portion 12 and a tail portion 14 contiguous with head portion 12 and extending to tail portion free end 16. Serrations (not shown) are formed on either or both of top and bottom sides 18 and 20 of tail portion 14. Head portion 12 includes pawl 22 extending into through passage 24. As is known, pawl 22 may be a plastic member integrally formed with cable tie 10 or may be a metal member.

[0017] Cable tie 10 is a molded plastic member, the making mold being constructed to impart undulation 26 to tail portion 14 at tail portion free end 16.

[0018] Referring to FIG. 3, mounting plate 28 defines apertures 30 and 32 extending therethrough. Undulation 26 of tail portion 14 is inserted into aperture 32, which is of a cross-dimension 34 less than the cross-dimension 36 of undulation 26. Undulation 26 is accordingly cross-wise compressed in the course of the insertion, as shown in a first stage of assembly of FIG. 3.

[0019] Referring to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com