Abradable device on the blower casing of a gas turbine engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

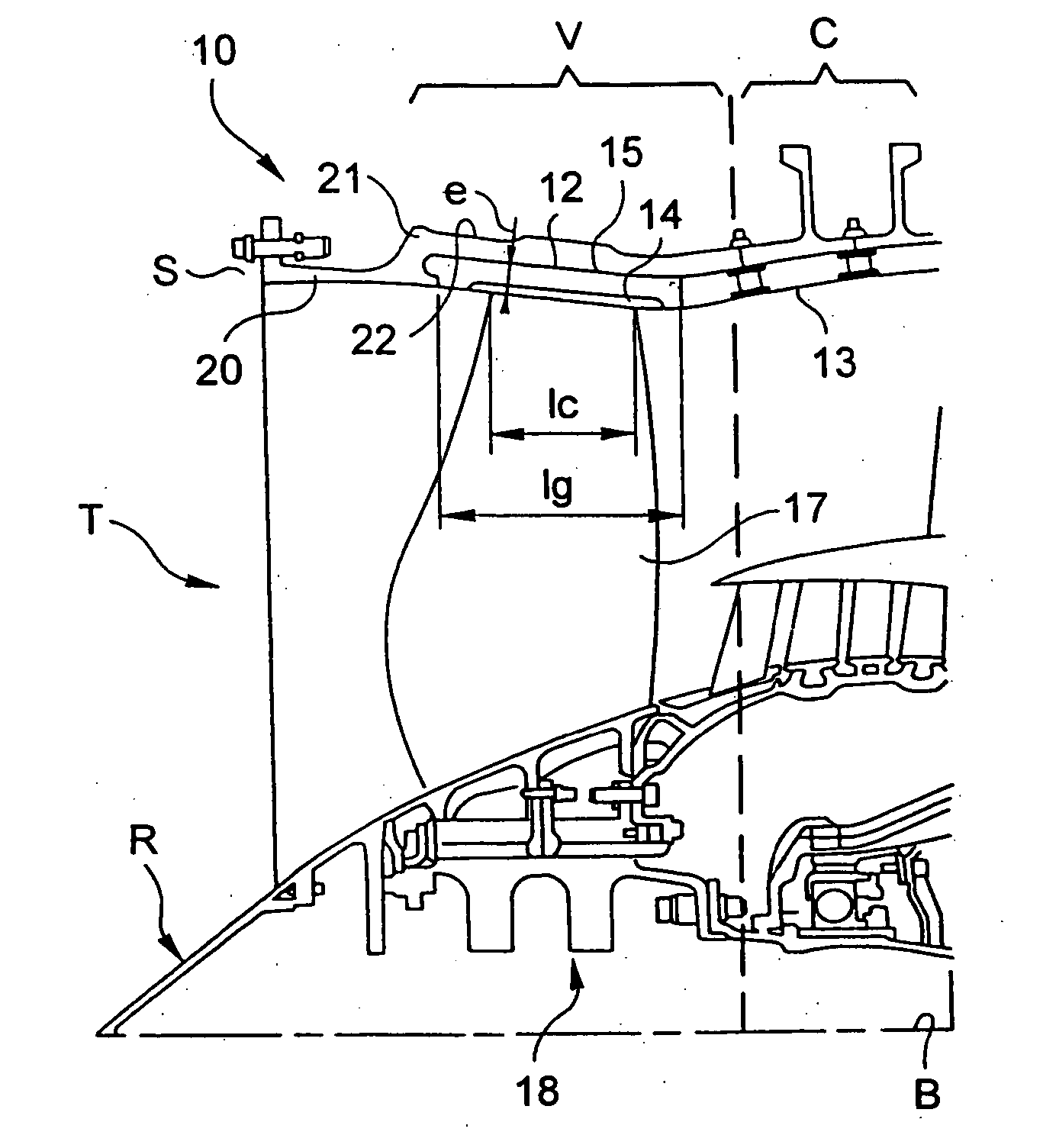

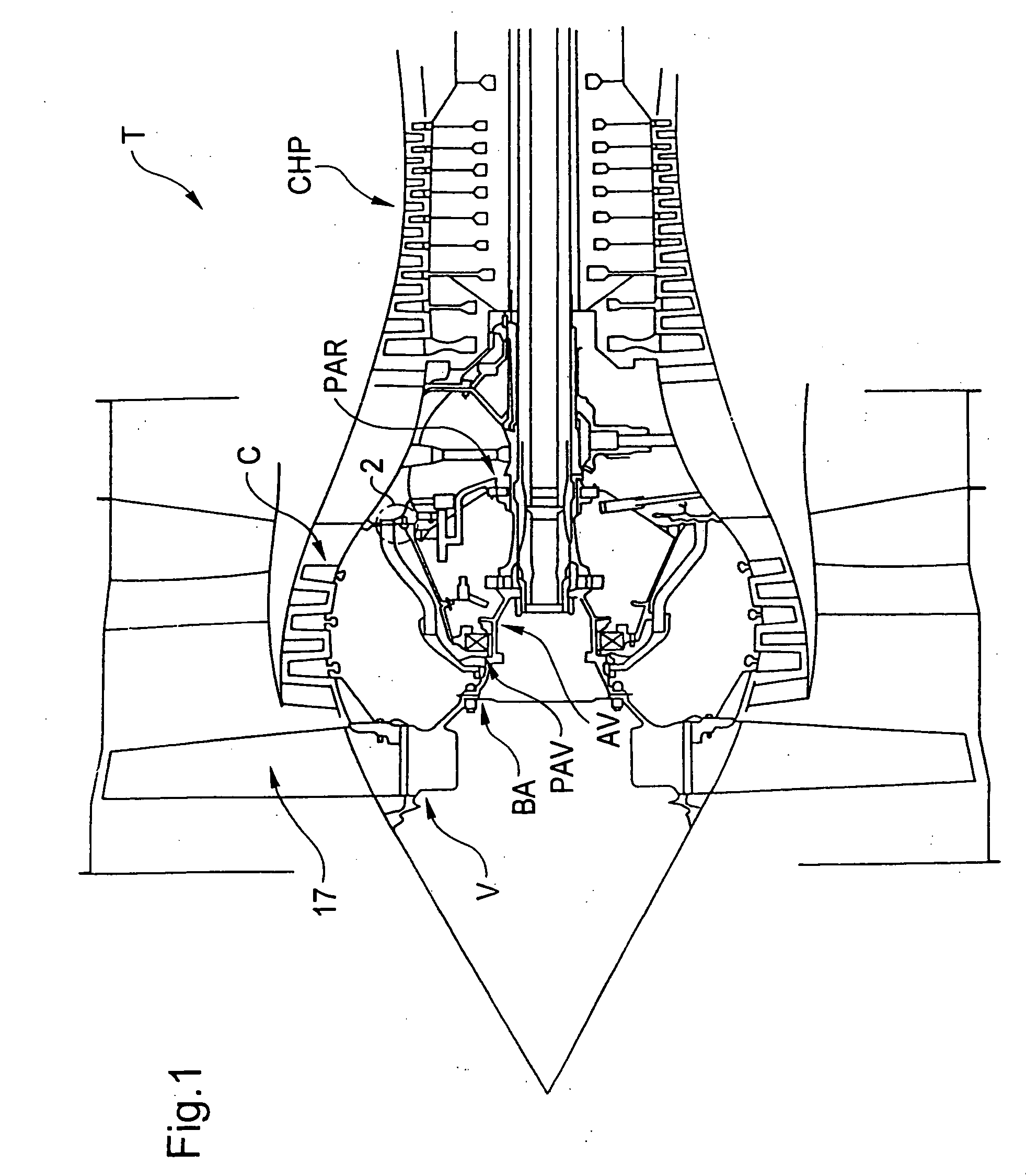

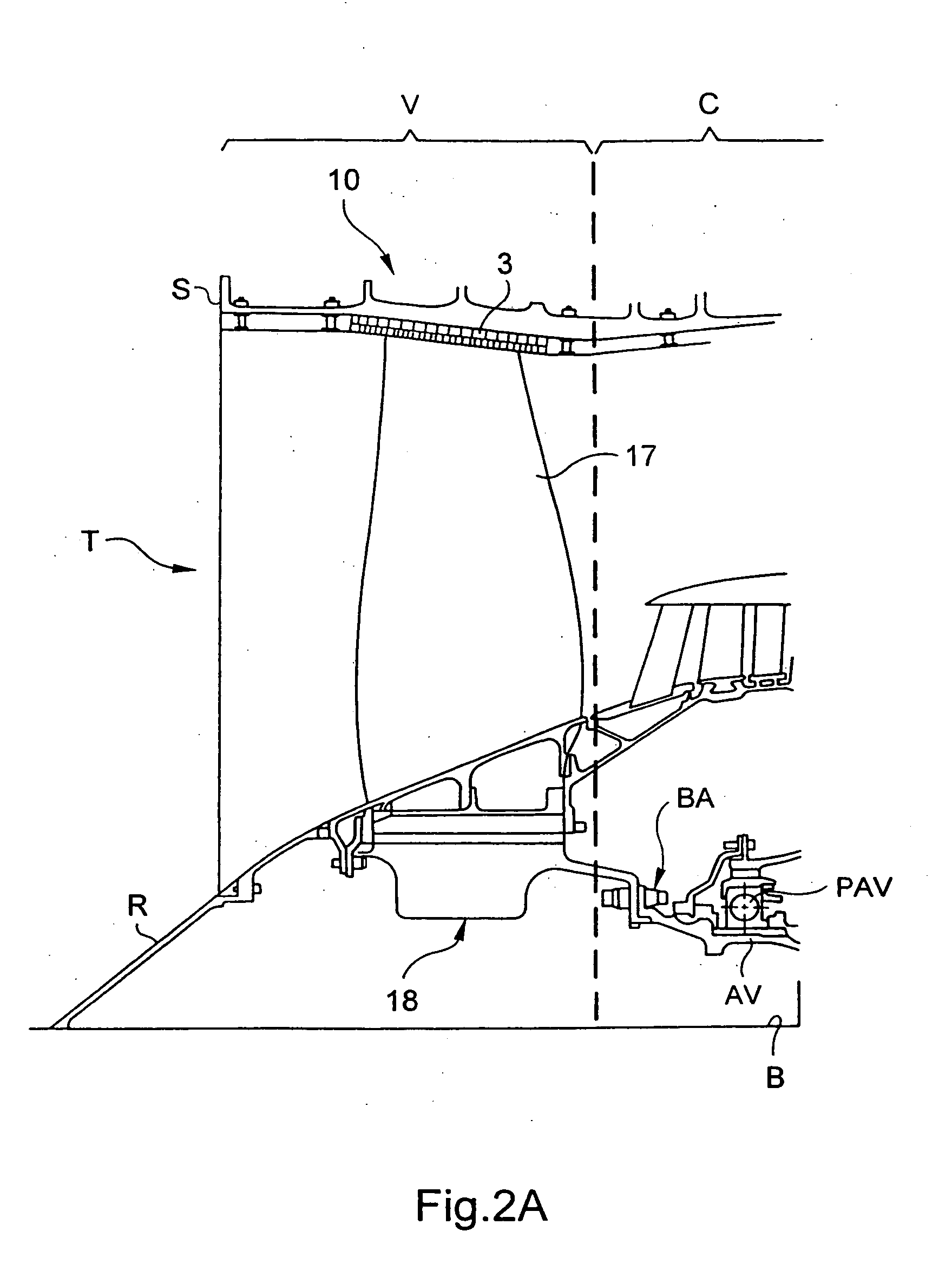

[0021]FIG. 1 depicts a section of a turbine engine T along its axis of rotation. This section comprises a blower V for accelerating the air before the entry to the stages of the compressor C, and then a high-pressure compressor CC. The blower V comprises a disc provided with blades 17 connected by screwing to the front end BA of a blower shaft AV mounted on a front bearing PAV and a rear bearing PAR as detailed in the application FR 2 752 024. The front and rear bearings are supported by support pieces connected to a fixed part of the turbine engine (the stator), at least one of the bearings being connected by connections which are sufficiently fragile to break when there is an excessive load on a blower blade. Such a bearing is referred to as a “fusible bearing”. These weak connections can be connections by screws whose cross-section is reduced over part of the length of the screw for example. Once the connection is broken, the bladed disc of the blower continues to turn freely, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com