Golf club and method for manufacturing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

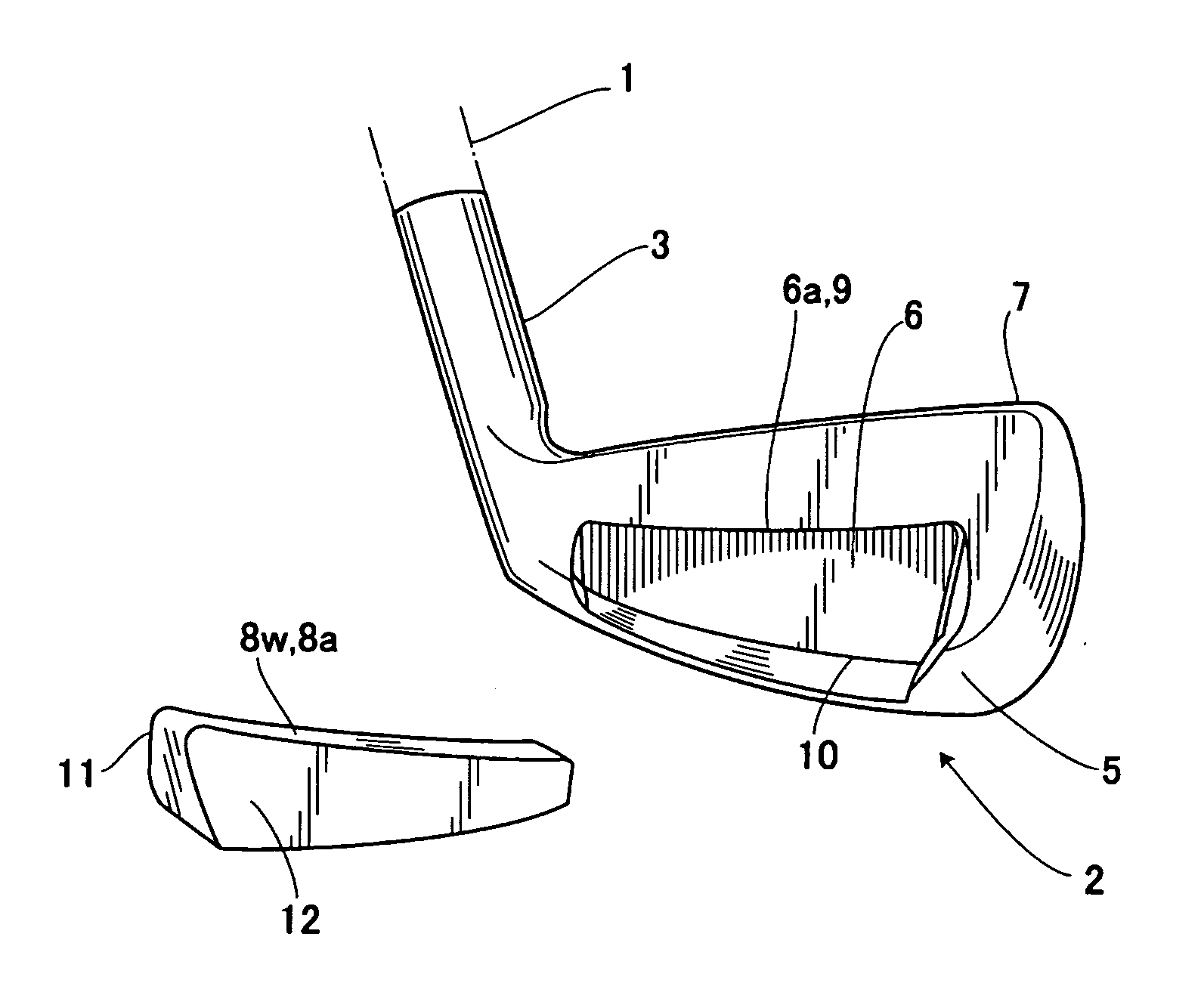

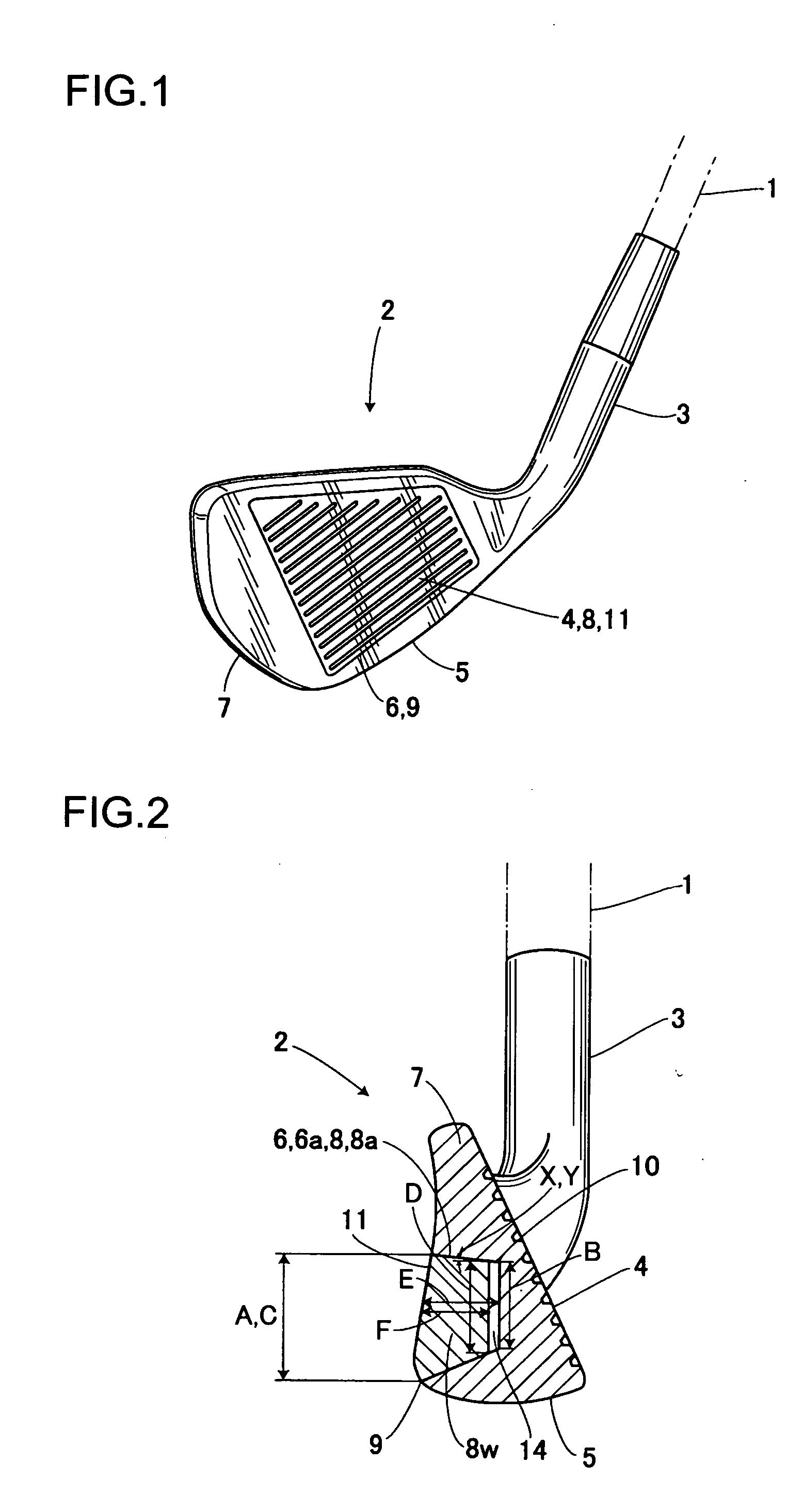

[0036] FIGS. 1 to 3 illustrate a A golf club of the present invention comprises a shaft 1 provided with a grip (not illustrated) on an upper end thereof, and a head 2 connected to a lower end of the shaft 1. The head 2 is formed with a hosel 3 on one side thereof as a shaft connecting portion protruding from the one side, a face 4 on a front side thereof, a sole 5 on a lower portion thereof, respectively. The head 2 having the hosel 3, the face 4 and the sole 5 comprises: a head body 7 as one member concavely formed with a receiving portion 6 on a rear side thereof; and a weight 8w as the other member of tabular fitted into the receiving portion 6. The head body 7 is made of an iron-based material manufactured by applying hot-forging to S20, but other kinds of materials, forgings can be properly applied. The weight 8w is made of a material having larger specific gravity than that of the head body 7. For instance, the weight 8w is made from tungsten, tungsten alloy.

[0037] An inner c...

second embodiment

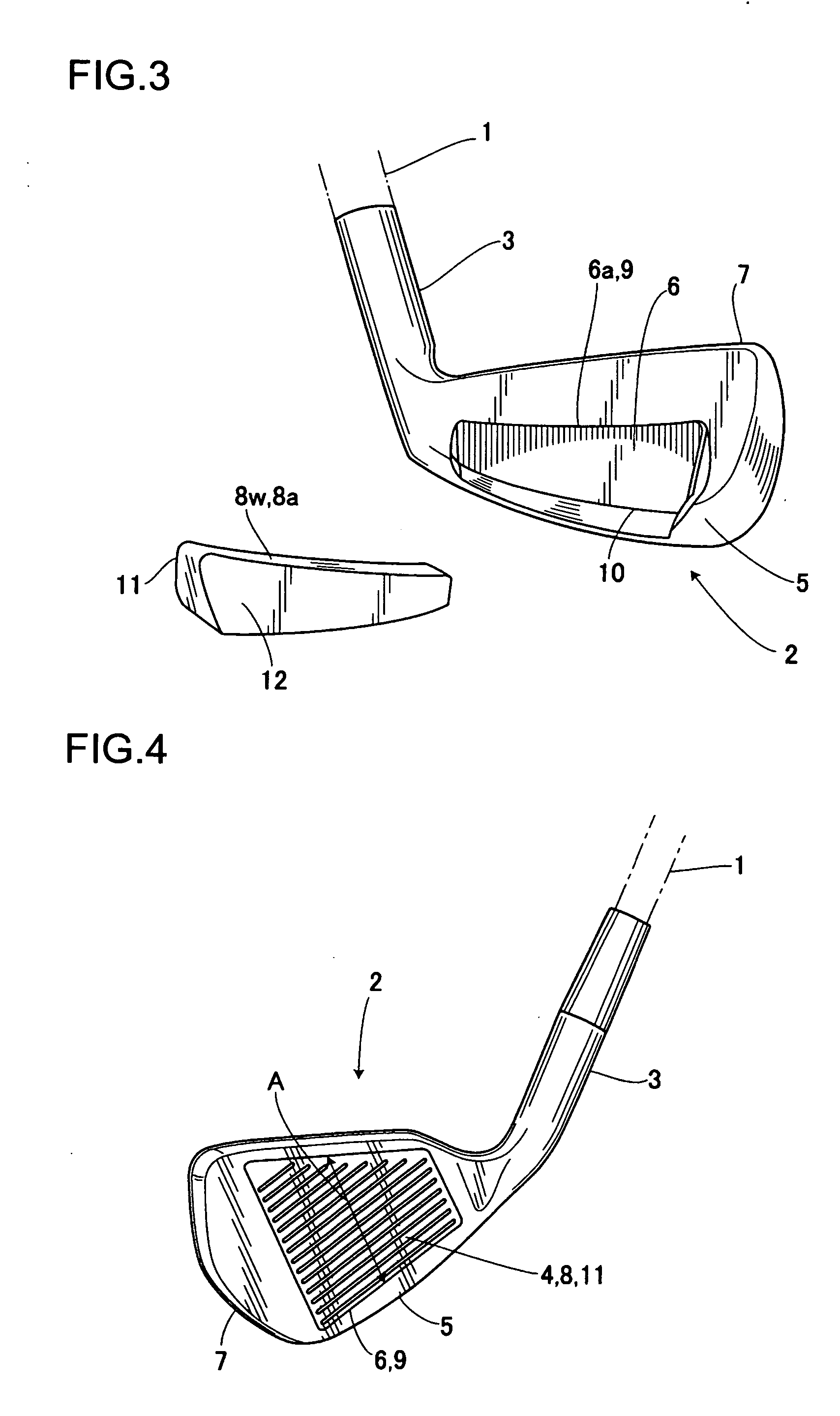

[0044] Next, the present invention will now be described with reference to FIGS. 4 to 7. The same reference numbers will denote the same structure portions, while detailed explanations thereof will be omitted. The head 2 having the hosel 3 and the sole 5 comprises: the head body 7 as one member concavely formed with the receiving portion 6 corresponding to the face 4; and a face member 8 as the other member of tabular fitted into the receiving portion 6. The head body 7 is made of an iron-based material, while the face member 8 is made from, for instance, titanium, titanium alloy, and thus they are made from different metals.

[0045] The inner circumference 6a of the receiving portion 6 is tapered so as to allow the width A of the aperture portion 9 of the concaved receiving portion 6 to be gradually wider than the width B of the recess portion 10 which extends from the aperture portion 9 toward the center of the head 2 with respect to the aperture portion 9. The recess portion 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com