Collar stiffening device and method of use

a collared and collared technology, applied in the direction of clothing, shirts, garments, etc., can solve the problems of haphazard use, inability to use stays in open collared single-layer knit shirts, curling through any length of wearing time, etc., and achieves sufficient stiffness and flexibility, convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

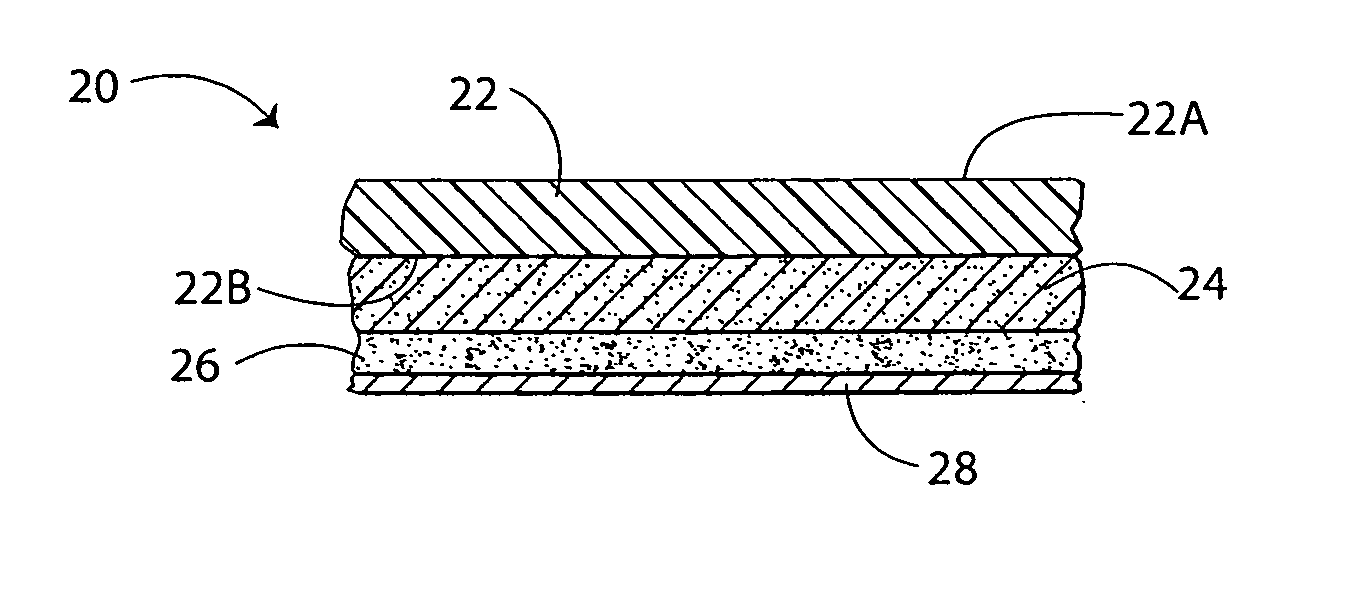

[0018] A prior art adhesive collar stiffening device is shown in FIG. 1 and generally designated 10. The collar support 10 comprises a thin flat relatively rigid base support member 12, a thin layer of pressure sensitive and water soluble adhesive material 14 covering one face of the support member, and a porous flexible backing 16 removably engaged with the adhesive covered face of the support member. As discussed hereinabove, the minimal clearance between flexible backing 16 and support member 12 makes the removal of flexible backing 16 extremely problematic and results in difficulty in use of prior art collar support 10 to ordinary users.

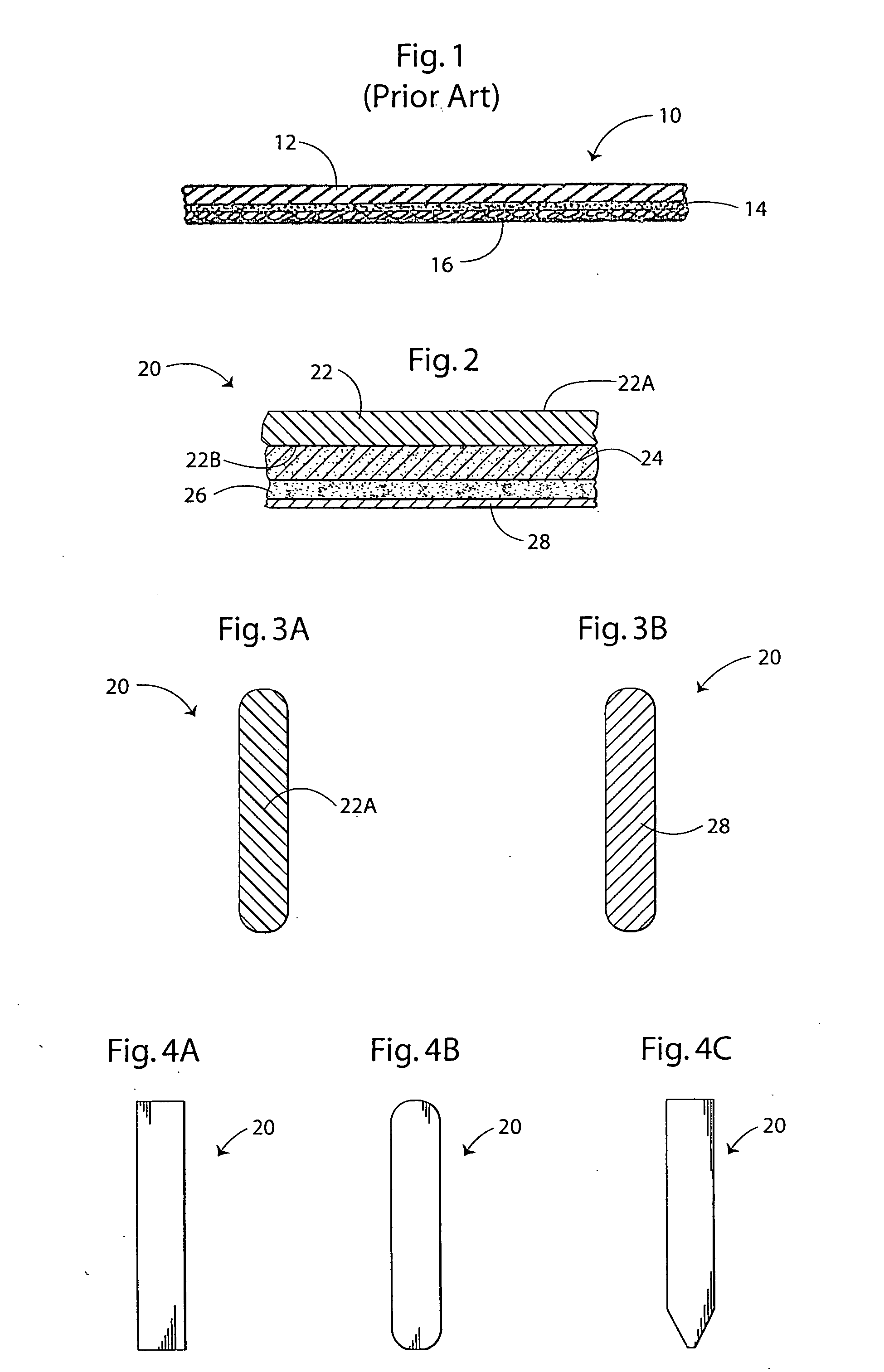

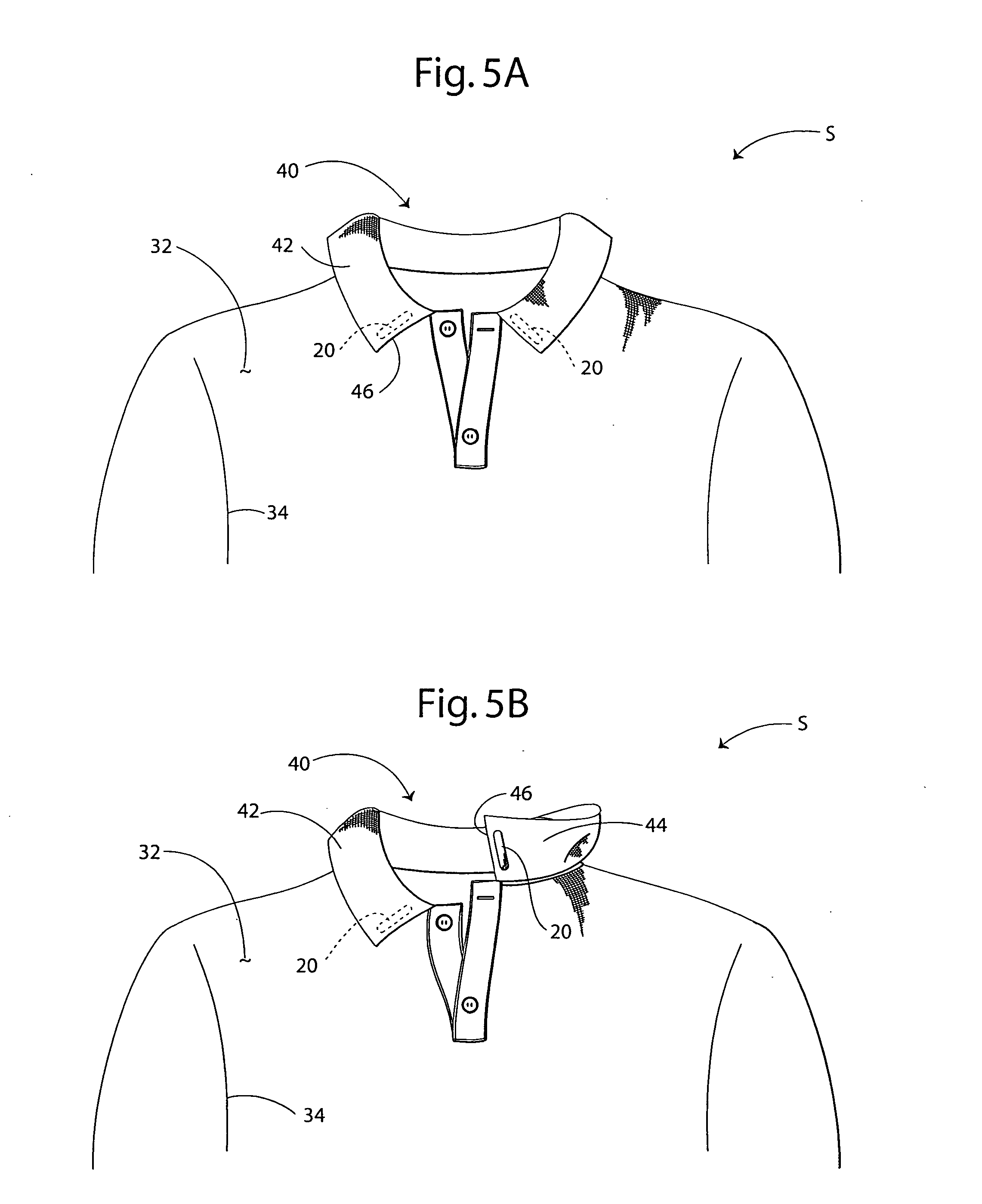

[0019] A preferred embodiment of the collar stiffening device of the present invention, generally designated 20, is shown in FIGS. 2, 3A and 3B and is designed to provide the long sought solution of relative ease of use of the collar stiffening device for stiffening shirt collars. Collar stiffening device 20 comprises a collar stay 22 having a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com