Method for adjusting the deformation geometry of a deformation tool in an optimising manners, corresponding deformation tool and appropriate test tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

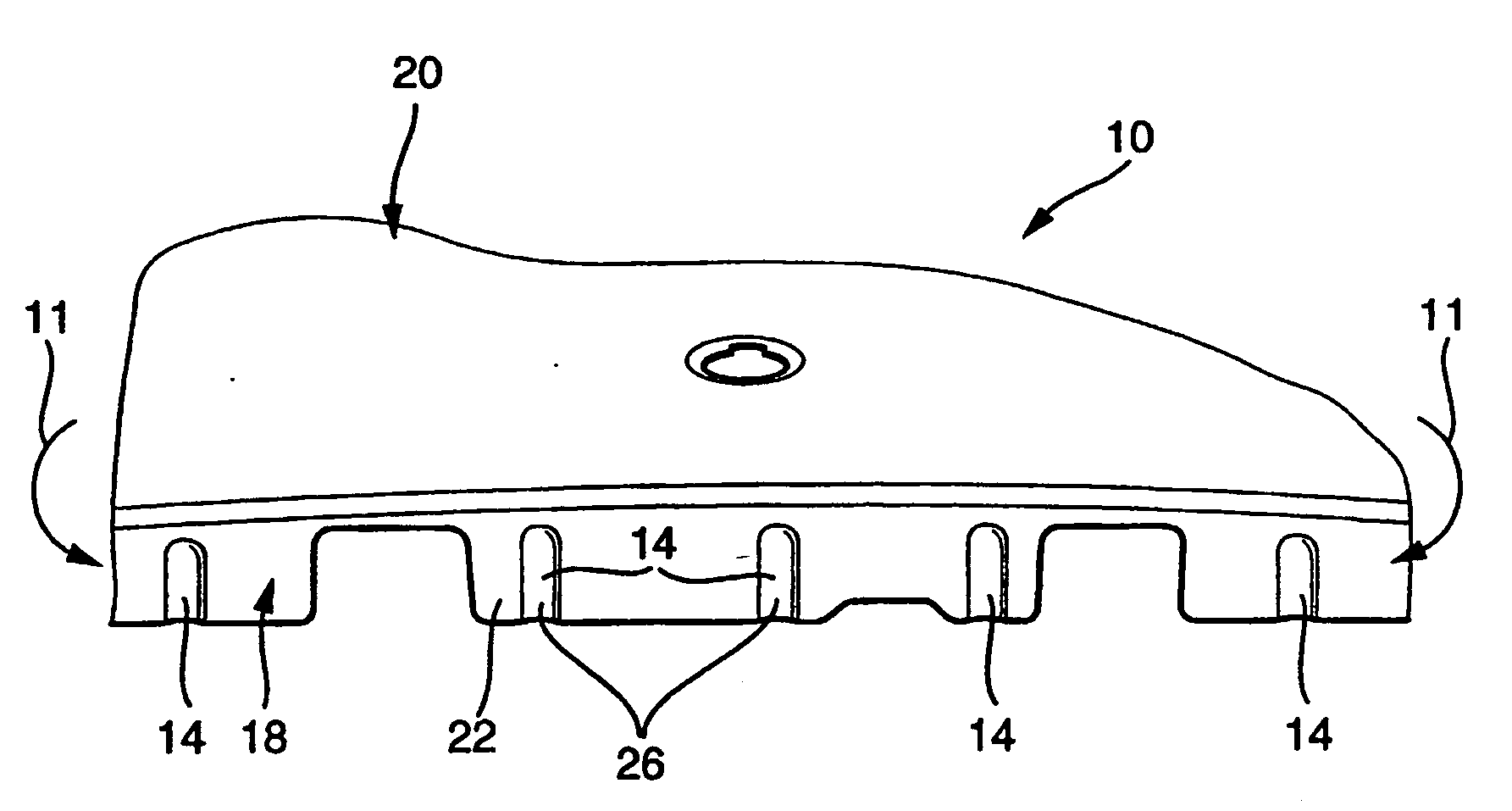

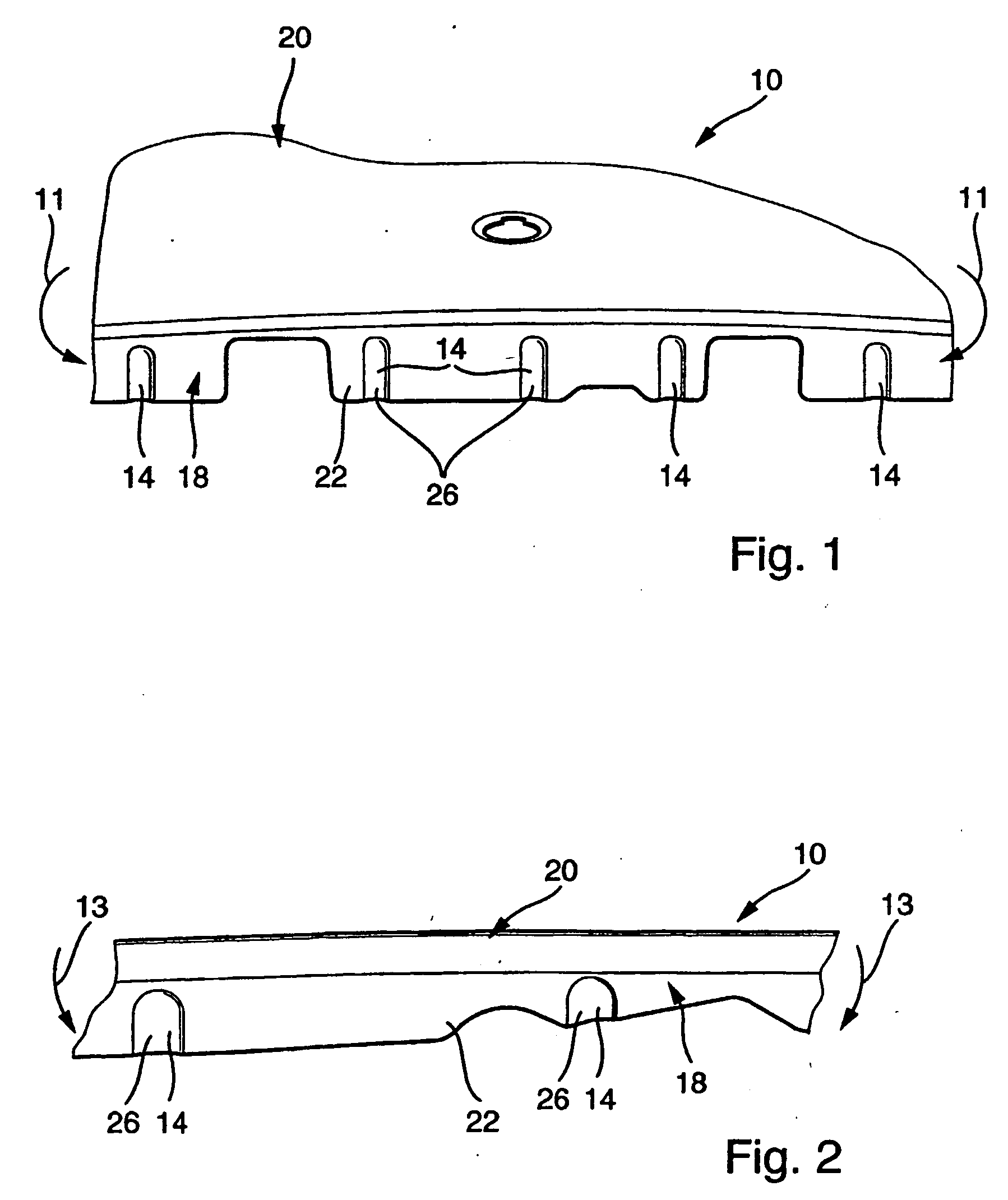

[0027]FIG. 1 shows in schematic partial representation a sheet metal 10 deep drawn on the basis of a deformation tool 12 shown in greater detail on the basis of FIG. 4, having the shape of a motor hood of a motor vehicle. The sheet metal 10 exhibits a geometric shape preformed by means of the deformation tool 12, which corresponds essentially to the desired intended geometry of the vehicle body part to be produced. However if there occurs an elastic spring back deformation which is fundamentally not to be avoided in the case of deep drawn aluminum sheet metal, strong, on the basis of which it is often not directly possible to achieve due to, even in the case of a correctly shaped deformation tool with respect to the deformation geometry, a sufficient precision of the deformation exactness of the sheet metal 10, in particular in regard to a previously provided sheet curvature in the main extension plane 20.

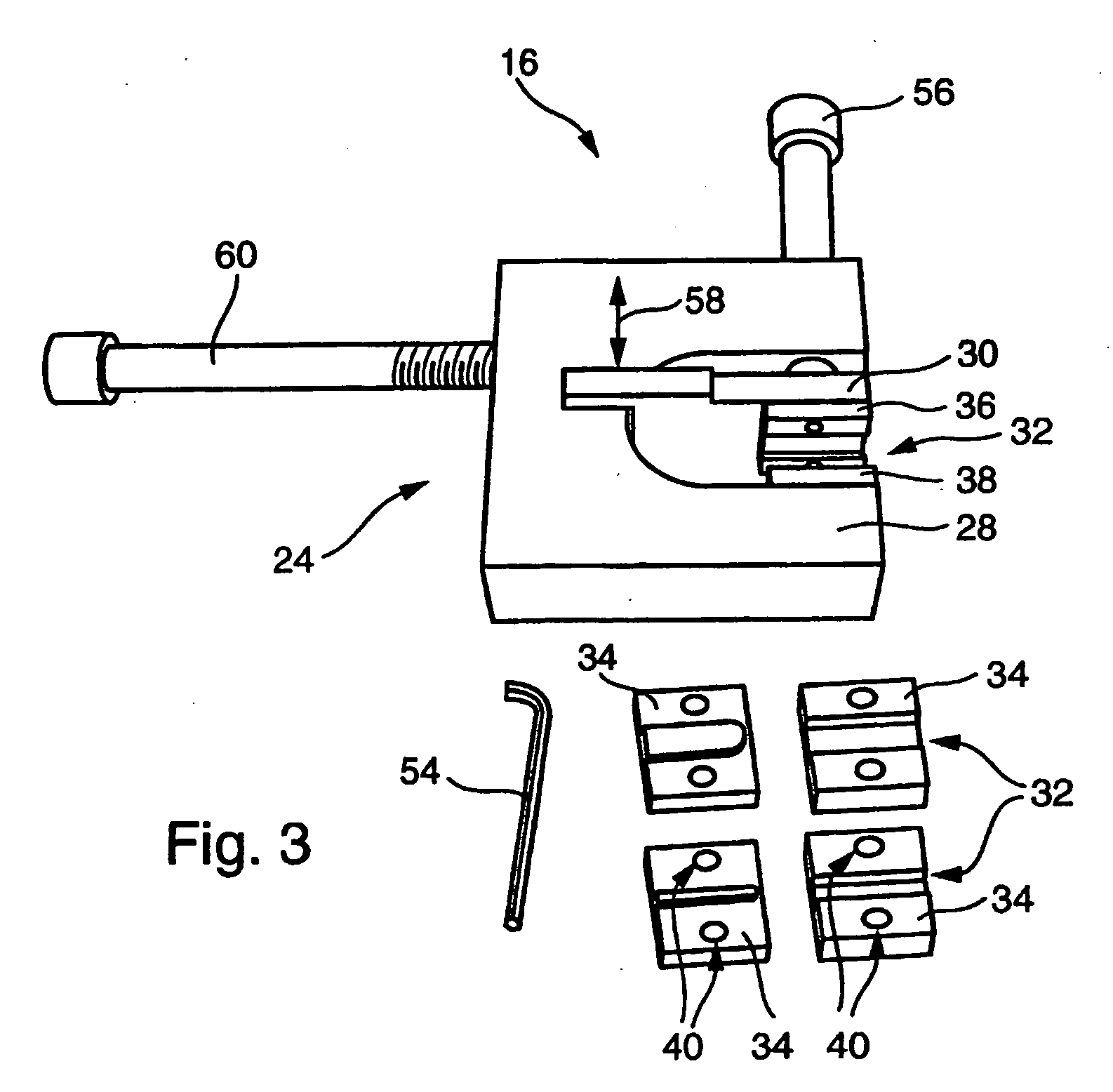

[0028] For adjusting or conforming the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Deformation enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com